Buoyant board filter

A filter tank and floating plate technology, applied in the direction of filtration separation, gravity filter, loose filter material filter, etc., can solve the problems of long drainage process, affecting the discharge of suspended solids at the far end, and affecting drainage time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

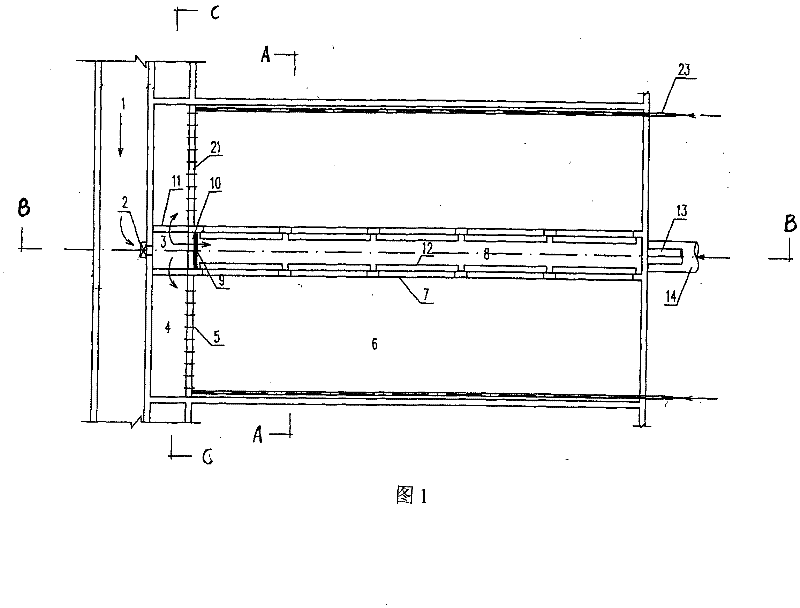

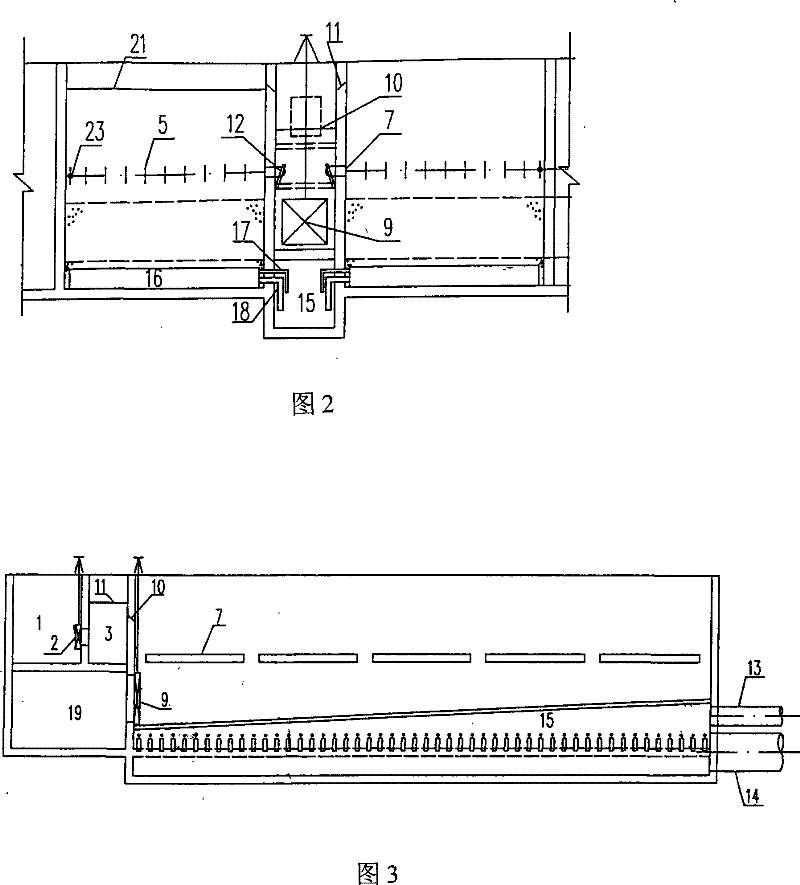

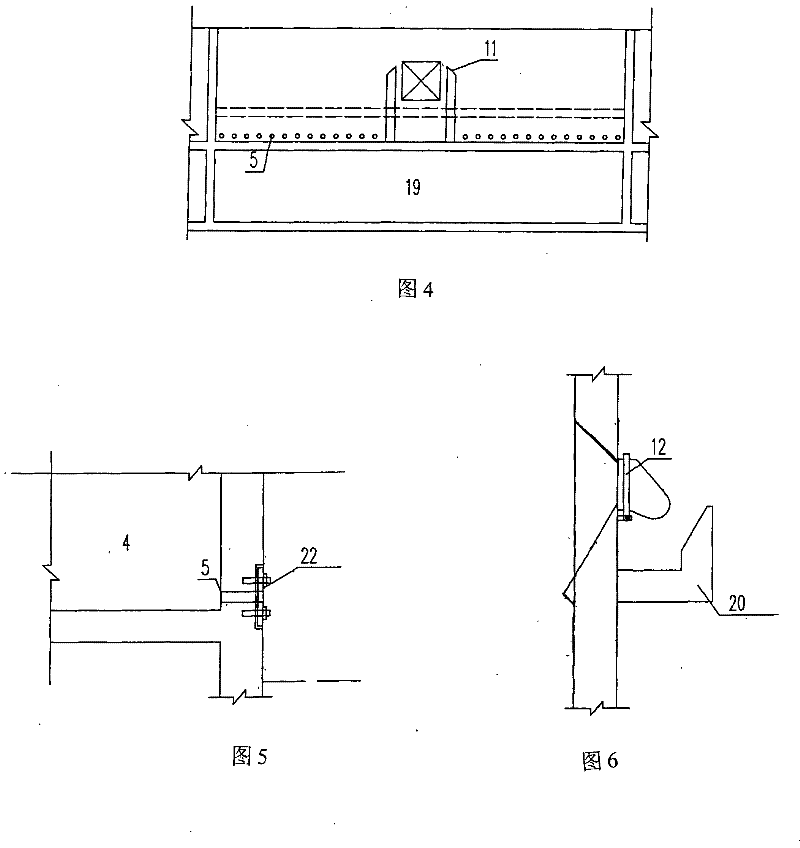

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] Such as figure 1 The shown embodiment is a single pool of floating plate filter, the pool is 15000mm long, 9600mm wide, and the actual filtration area is 120m 2 , the design filtration rate gm / h processing capacity is 23,000 m 3 / d, there is a drainage channel in the center of the filter, with a net width of 1200mm, the side wall of the drainage channel is 200mm wide, and the height reaches the top of the pool. There are 5 flat rectangular drainage holes and floating plates on each side wall. The length of the drainage hole is 2600mm, and the height is 200mm. The spacing is 300mm, and the bottom of the hole is about 500mm higher than the surface of the filter material. The diameter of the water distribution hole in the water inlet distribution chamber is 50mm, the distance between the centers is 150mm, and the elevation of the center of the hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com