Ethanol dehydration fluidized bed process and reaction

A fluidized bed reactor and ethanol dehydration technology, which is applied in chemical instruments and methods, bulk chemical production, chemical/physical processes, etc., can solve the problems of high energy consumption, severe corrosion, heat transfer effect and poor catalyst stability of ethanol dehydration process and other problems, to achieve the effect of saving the amount of lye, solving the corrosion problem, and reducing the amount of entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

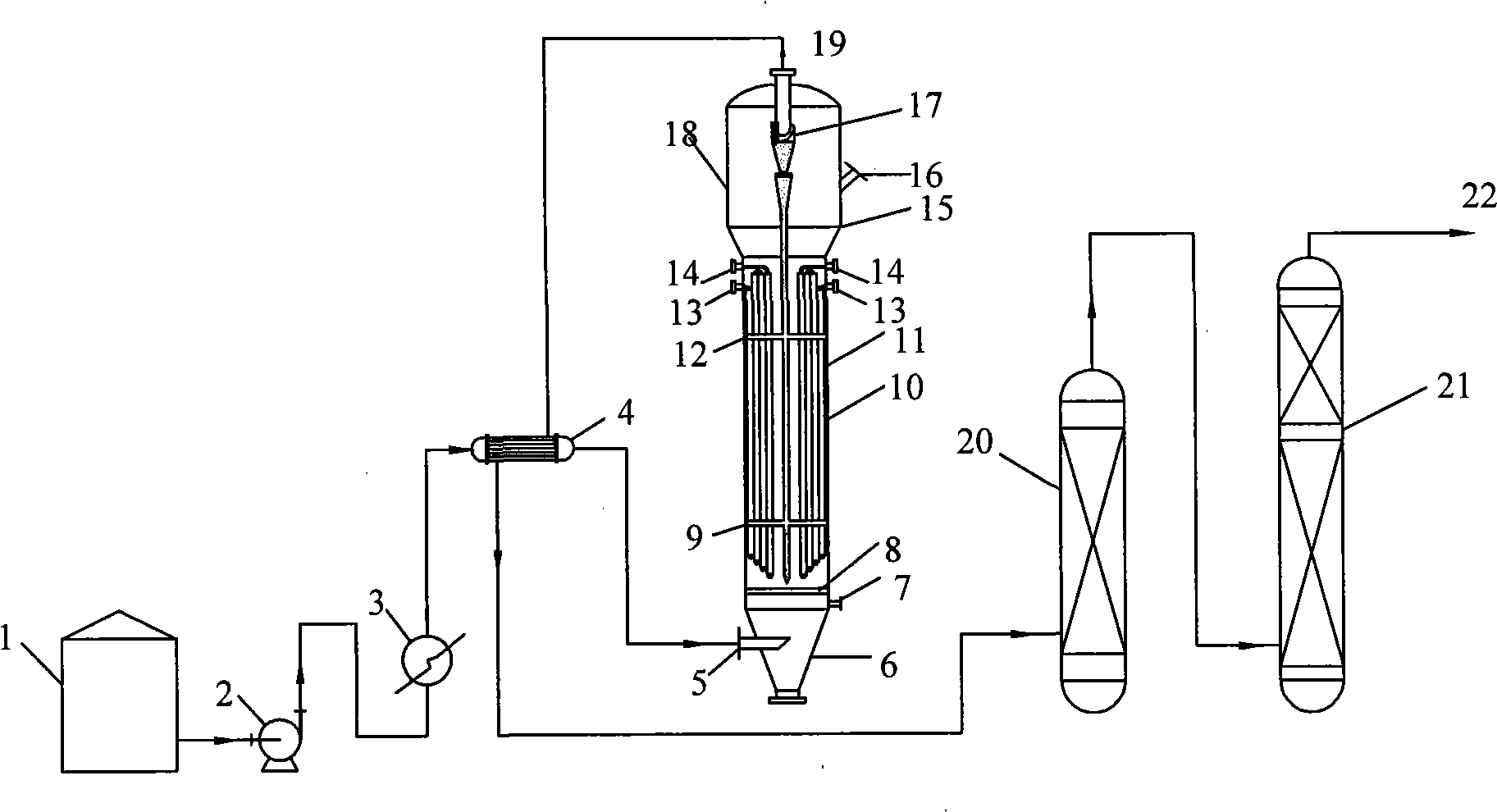

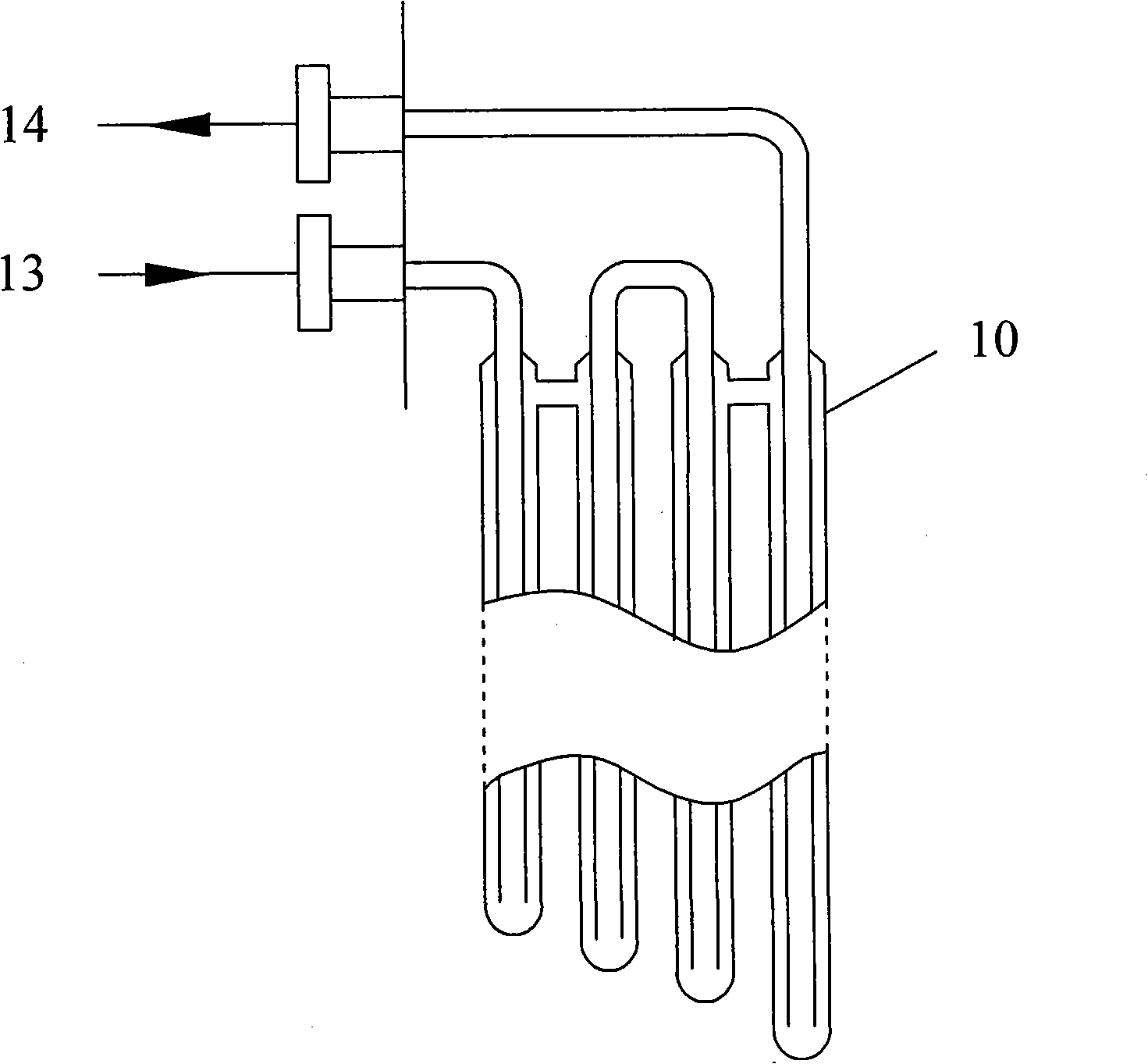

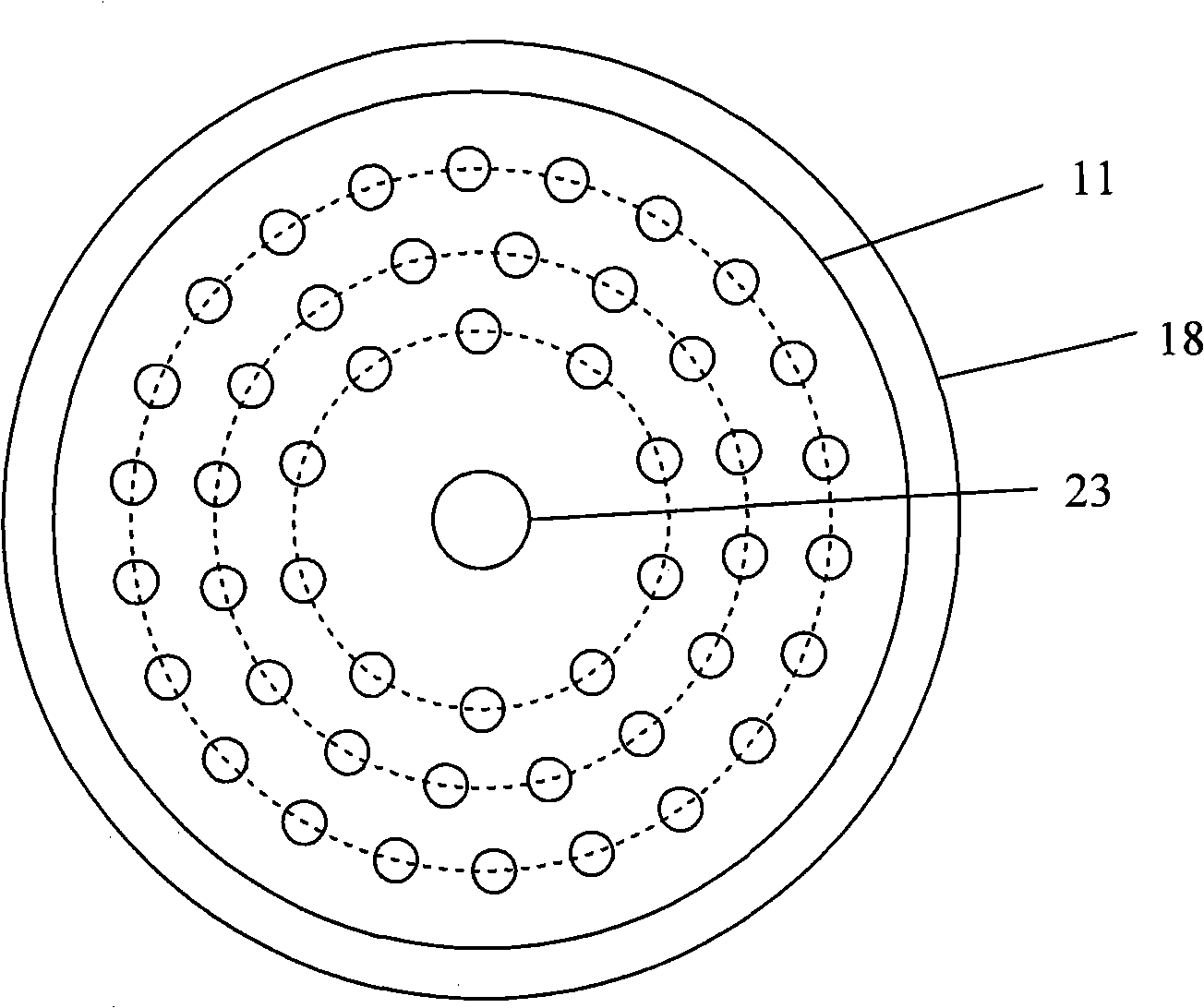

[0037] The lower end of the housing 11 of the fluidized bed reactor is sealed with the upper end of the lower cone 6, and a feed gas inlet 5 for the fluidized bed reactor is provided in the middle of the lower cone 6, corresponding to the housing 11 and the lower cone 6. A catalyst discharge port 7 is provided at the sealed position, and a gas distribution plate 8 is provided at the lower part of the casing 11 and the upper part of the catalyst discharge port 7 to collect the sinking catalyst. Two casing fixing pipes are provided in the housing 11, respectively the lower casing fixing pipe 9 and the upper casing fixing pipe 12, to fix the central conduit 23 and the lower end of the cyclone separator 17 built in the fluidized bed reactor. The finger sleeve bundle 10 is arranged between the cyclone separator 17 and the casing 11 . The heat transfer oil outlet and inlet of the finger-shaped bushing bundle 10 are respectively arranged on the upper part of the housing 11 . The low...

Embodiment 2

[0040] When ethanol dehydration is carried out in this process, the ZSM-5 molecular sieve catalyst modified by lanthanum with an average particle size of 300 μm is first loaded into the fluidized bed reactor through the catalyst feed port, and the heat transfer oil is used to preheat the fluidized bed and the catalyst. When reaching the reaction temperature of 250°C, the ethanol raw material with a concentration of 50wt% is preheated through the preheater, and the vaporized gas enters the inlet of the fluidized bed reactor through the heat exchanger, and the catalyst begins to fluidize under the action of the air flow, and after stabilization The pressure in the reactor is kept constant, the larger catalyst particles return to the fluidized bed cylinder through the expansion section, and the smaller catalyst particles return to the gas distribution plate through the cyclone separator through the central conduit. The gas after the reaction enters the water washing tower after he...

Embodiment 3

[0042] When ethanol dehydration is carried out in this process, the SAPO-31 molecular sieve catalyst modified by cerium with an average particle size of 300 μm is first loaded into the fluidized bed reactor through the catalyst feed port, and the heat transfer oil is used to preheat the fluidized bed and the catalyst. When reaching the reaction temperature of 260°C, the ethanol raw material with a concentration of 65wt% is preheated through the preheater, and the vaporized gas enters the inlet of the fluidized bed reactor through the heat exchanger, and the catalyst begins to fluidize under the action of the air flow, and after stabilization The pressure in the reactor is kept constant, the larger catalyst particles return to the fluidized bed cylinder through the expansion section, and the smaller catalyst particles return to the gas distribution plate through the cyclone separator through the central conduit. The reacted gas enters the water washing tower after being exchange...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com