Bright brush plating nano-chromium solution and preparation thereof

An electric brush plating and nanotechnology, which is applied to electric brush plating solution, the preparation of the bright electric brush plating nano-chromium solution, and the field of bright electric brush plating nano-chromium solution, can solve the problem of low wear resistance, poor brightness, and reduction of electric brushing. The concentration of chromic anhydride in the chrome plating solution has the effect of broadening the scope of the process and promoting the application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Pour 200g of chromic anhydride into a beaker, add 1000ml of distilled water, measure sulfuric acid into the beaker, the concentration ratio of sulfuric acid and chromic anhydride is 1:100, stir with a magnetic stirrer to form a mixed solution, then add 6g of potassium iodide, 13g of trichloroacetic acid, and 3g of fluorine Sodium chloride, stirred until all dissolved, filtered, that is.

Embodiment 2

[0059] Pour 300g of chromic anhydride into a beaker, add 1000ml of distilled water, measure sulfuric acid and add it to the beaker, the concentration ratio of sulfuric acid and chromic anhydride is 1:100, stir with a magnetic stirrer to form a mixed solution, then add 8g of potassium iodide, 15g of trichloroacetic acid, 5g of fluorine Sodium chloride, stirred until all dissolved, filtered, that is.

Embodiment 3

[0061] Pour 250g of chromic anhydride into a beaker, add 1000ml of distilled water, measure sulfuric acid into the beaker, the concentration ratio of sulfuric acid and chromic anhydride is 1:100, stir with a magnetic stirrer to form a mixed solution, then add 7g of potassium iodide, 14g of trichloroacetic acid, 4g of fluorine Sodium chloride, stirred until all dissolved, filtered, that is.

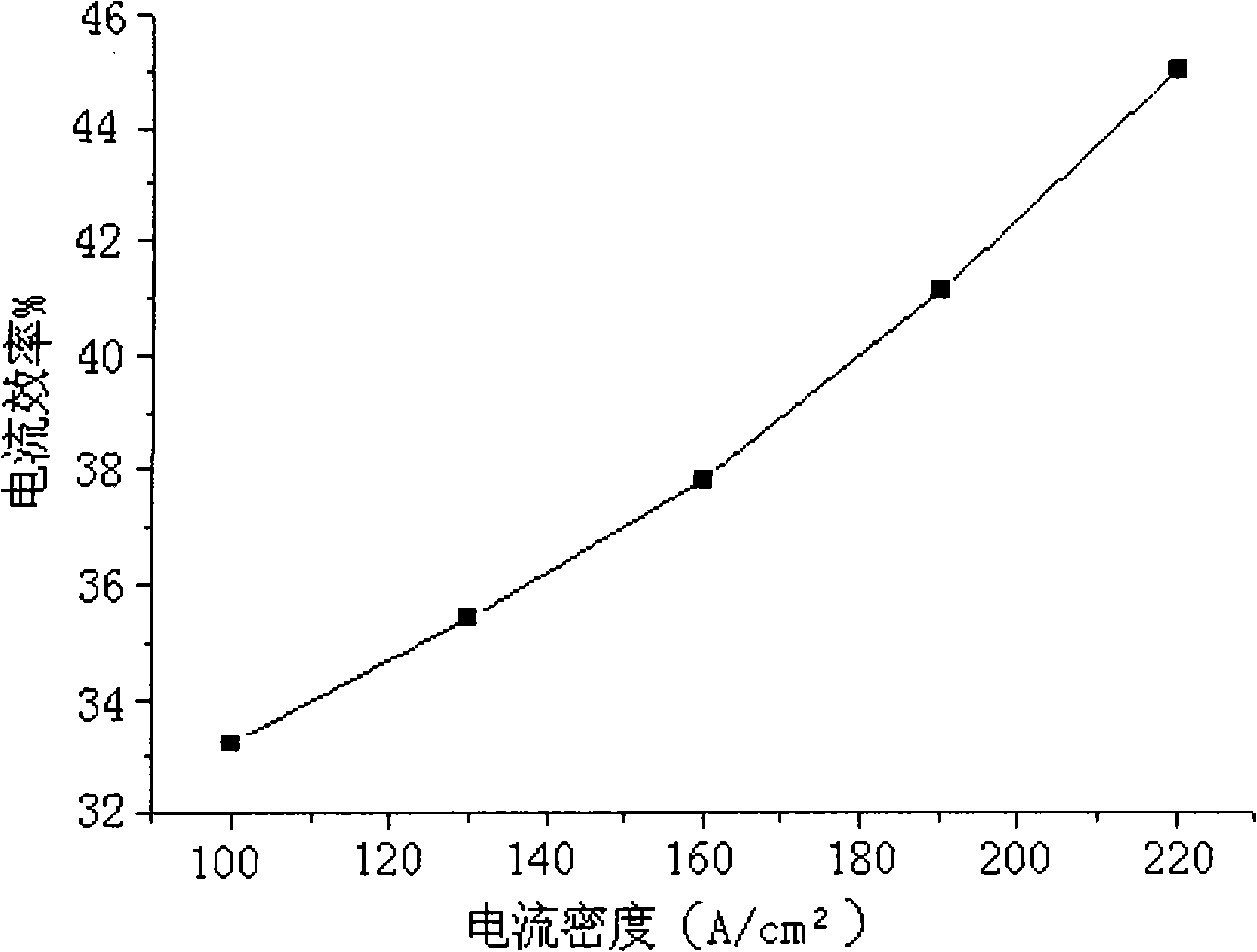

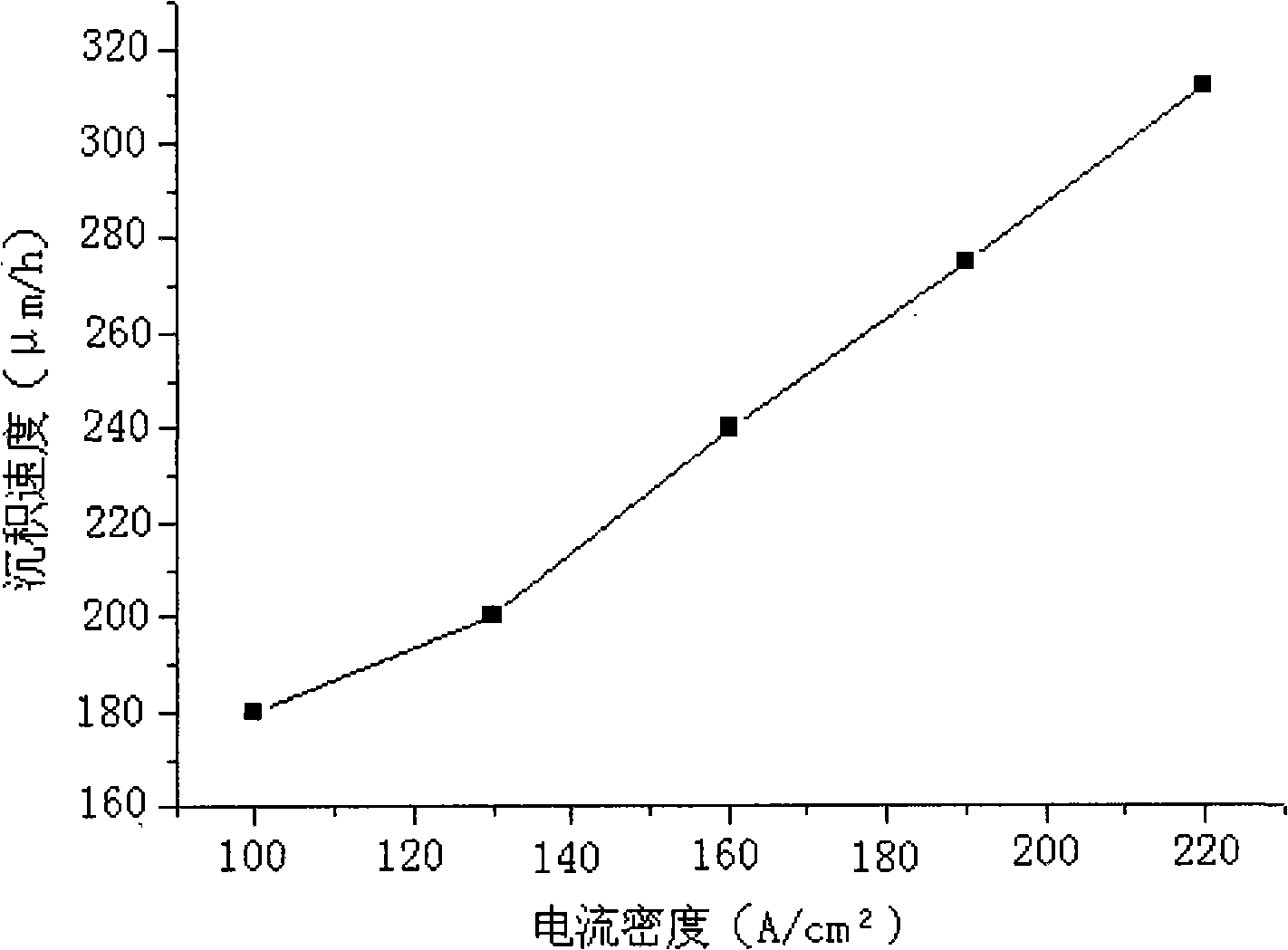

[0062] The invention is used for brush chrome plating. The table below lists the performance test data of the chrome coating under the condition of electrochrome plating, existing brush chrome plating and brush chrome plating of the present invention.

[0063] Table Chromium coating properties

[0064] Test items

[0065] Hardness (HV)

[0066] The above table shows that compared with the conventional brush chrome plating, the brush plating nano-chromium solution of the present invention greatly improves the relative brightness of the chromium plating layer, the coati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com