LCD hard type protection film

A liquid crystal display and protective film technology, which is applied in the field of composite films, can solve the problems of small surface friction coefficient, lack of support force, long transportation time, etc., and achieve the effect of soft surface, strong support force and scratch prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

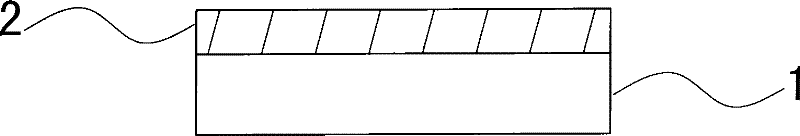

[0024] 1. If figure 1 As shown, a PET film with a thickness of 0.125 cm is selected to construct a PET layer 1, and a layer of glue with a thickness of 0.01 cm is coated on the PET film to form an adhesive layer 2;

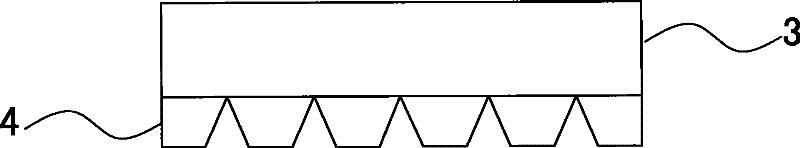

[0025] 2. If figure 2 , 3 As shown in and 4, the PE textured film with antistatic function is selected, the thickness of the PE layer 3 of the PE textured film is 0.03cm, the thickness of the adhesive layer 4 of the PE textured film is 0.02cm, and the convexity of the PE textured film is 0.03cm. The vertical distance between the top of the 6 and the bottom of the hole is 0.02cm;

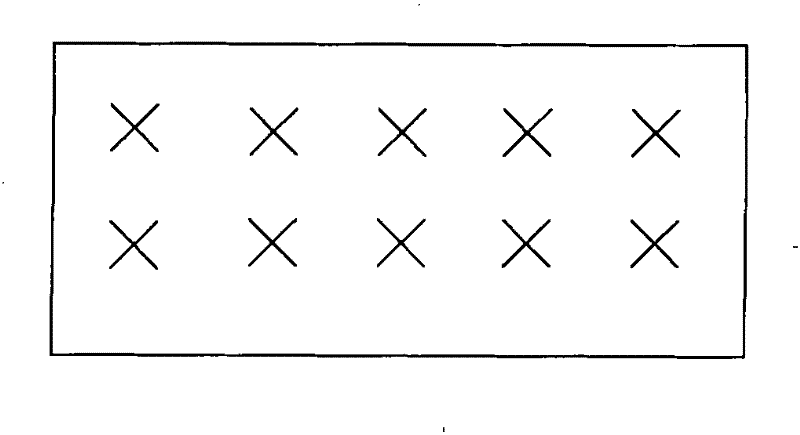

[0026] 3. Composite coating of PET film with glue layer and PE textured film with roller machine, the composite pressure is 7kg / m 2 , constituting the hard protective film of the liquid crystal display, after rolling and laminating, the surface of the PE layer of the hard protective film has a raised structure 7, such as Figure 5 shown;

[0027] 4. Face the PE film of the hard pro...

Embodiment 2

[0029] 1. If figure 1 As shown, choose 0.075cm thick PET film;

[0030] 2. If figure 2 , 3 As shown in and 4, select the PE textured film, the thickness of the PE layer is 0.04cm, the thickness of the adhesive layer is 0.025cm, and the depth of the cavity is 0.025cm;

[0031] 3. Use a coating machine to coat a layer of glue with a thickness of 0.008cm on the PET film, and then use a compound roller to compound the glue-coated PET film and PE textured film, and the compound pressure is 6kg / m 2 , constituting the hard protective film of the liquid crystal display, after rolling and laminating, the surface of the PE layer of the hard protective film has a raised structure, such as Figure 5 shown;

[0032] 4. Face the PE film of the hard protective film to the liquid crystal display and cover the display surface of the liquid crystal module, and use adhesive tape to fix the periphery of the hard protective film to protect the liquid crystal display and prevent the display su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com