Method for manufacturing high-efficiency silicon solar cell sheet

A silicon solar cell, high-efficiency technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of difficult processing, high production cost, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] 1. Preparation of oxide phosphorus source or silicon dioxide phosphorus latex source:

[0017] The oxide phosphorus source is modulated by glass powder and ammonium dihydrogen phosphate.

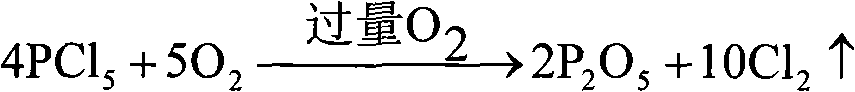

[0018] The silicon dioxide phosphorus latex source is prepared from ethyl orthosilicate and phosphorus pentoxide.

[0019] 2. Specific operation steps:

[0020] 1. Remove the damaged layer on the surface of the P-type silicon wafer by chemical etching, texturing and chemical cleaning according to the conventional method.

[0021] Although the silicon wafer has been cleaned after cutting, there are still grease, metal and other impurities and dirt on the surface. In addition, there is a layer of damaged layer on the surface of the silicon wafer after cutting. The above-mentioned impurities will have a certain impact on the subsequent processes and the performance of the battery. These can be processed through cleaning, damage removal and texturing.

[0022] Texturing is the use of l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com