High manganese steel casting grain refinement casting technique

A casting process, high-manganese steel technology, applied in the direction of manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problems of micro-cracks, coarse grains, looseness, etc., to increase grain refinement, grain refinement, The effect of reducing the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

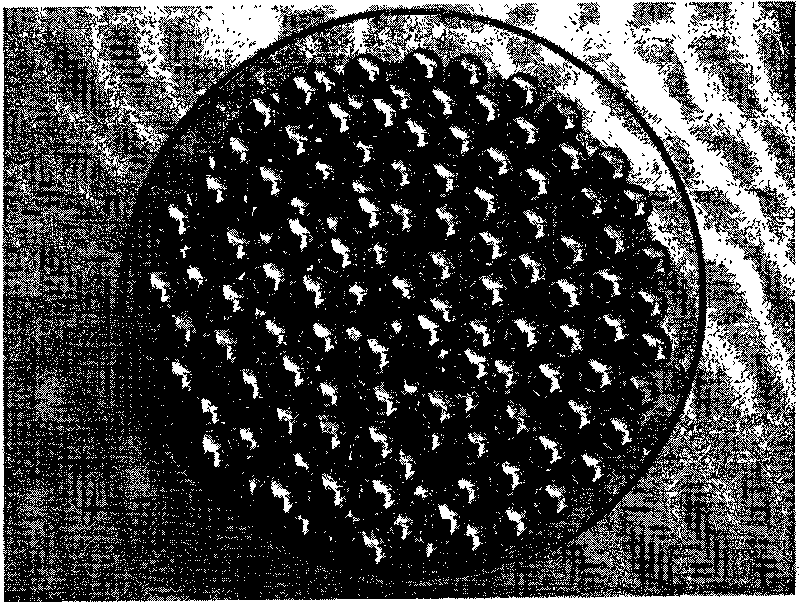

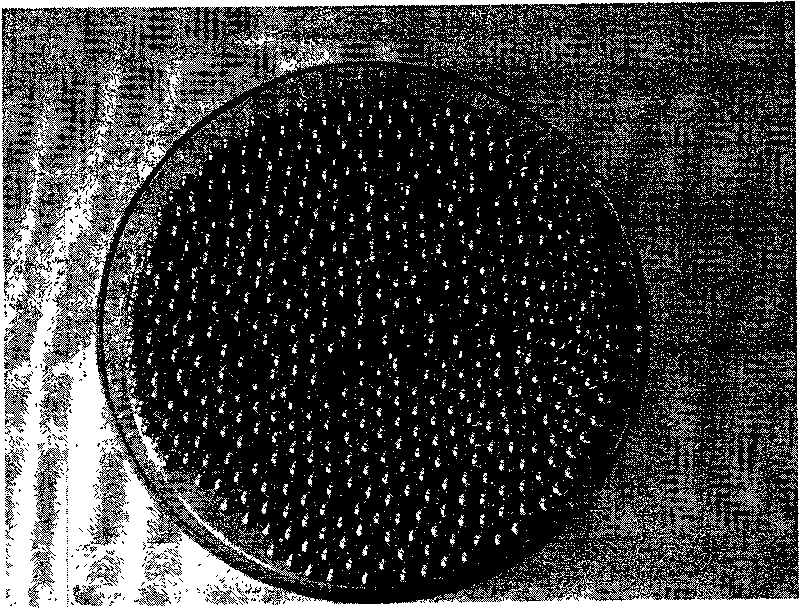

[0044] Such as figure 2 As shown, use thermal insulation riser and thermal insulation covering agent. The temperature of the molten steel is 1580°C. It is refined in the refining ladle to remove the inclusions. The weight of the molten metal is 0.6 tons. The pouring time is 32 seconds. The pouring temperature is 1480°C. Pouring under the protection of argon. Add 5% of the total weight of molten steel from the pouring system during the pouring process, and the size is 2mm metal particles, the metal particles are ZG 55, and the metal particle temperature is 180°C; the metal particles start to be added when the casting is poured for 11 seconds, and the metal particle addition time is 12 seconds. The casting adopts the hot boxing process, and the thermal cutting riser is cut by gas cutting method. The temperature of the thermal cutting riser is 650°C. After cutting, it is sent to the heat treatment kiln for homogenization treatment. The homogenization temperature is 1080°C and...

Embodiment 2

[0049] The difference from Example 1 is:

[0050] Such as figure 2 As shown, use thermal insulation riser and thermal insulation covering agent. The temperature of the molten steel is 1560°C. It is refined in the refining ladle to remove inclusions. The weight of the molten metal is 0.6 tons. The pouring time is 30 seconds. The pouring temperature is 1470°C. Add 2% of the total weight of molten steel from the pouring system during the pouring process, and the size is 5mm metal particles, the metal particles are ZG65, and the metal particle temperature is 245°C; the metal particles start to be added when the casting is poured for 10 seconds, and the metal particle addition time is 14 seconds. The casting adopts the hot-boxing process, and the hot-cut riser is cut by gas cutting method. The temperature of the hot-cut riser is 630°C. After cutting, it is sent to the heat treatment kiln for homogenization treatment. The homogenization temperature is 1075°C and the holding time...

Embodiment 3

[0054] The difference from Example 1 is:

[0055] Such as figure 2 As shown, use thermal insulation riser and thermal insulation covering agent. The temperature of the molten steel is 1590°C. It is refined in the refining ladle to remove inclusions. The weight of the molten metal is 0.6 tons. The pouring time is 28 seconds. The pouring temperature is 1480°C. Add 1.5% of the total weight of molten steel from the pouring system during the pouring process, and the size is 10mm metal particles, the metal particles are ordinary high manganese steel, the temperature of the metal particles is 320°C; the metal particles start to be added when the casting is poured for 14 seconds, and the metal particle addition time is 8 seconds. The casting adopts the hot boxing process, and the thermal cutting riser is cut by gas cutting method. The temperature of the thermal cutting riser is 600°C. After cutting, it is sent to the heat treatment kiln for homogenization treatment. The homogeniza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com