Biologic oxidation reactor for refractory auric sulfide ore

A biological oxidation and reactor technology, applied in metallurgical reaction equipment and biological fields, can solve the problems that the effect has not been fully confirmed, and achieve the effects of stable bed medium, improved residence time distribution, and wide operating range of flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

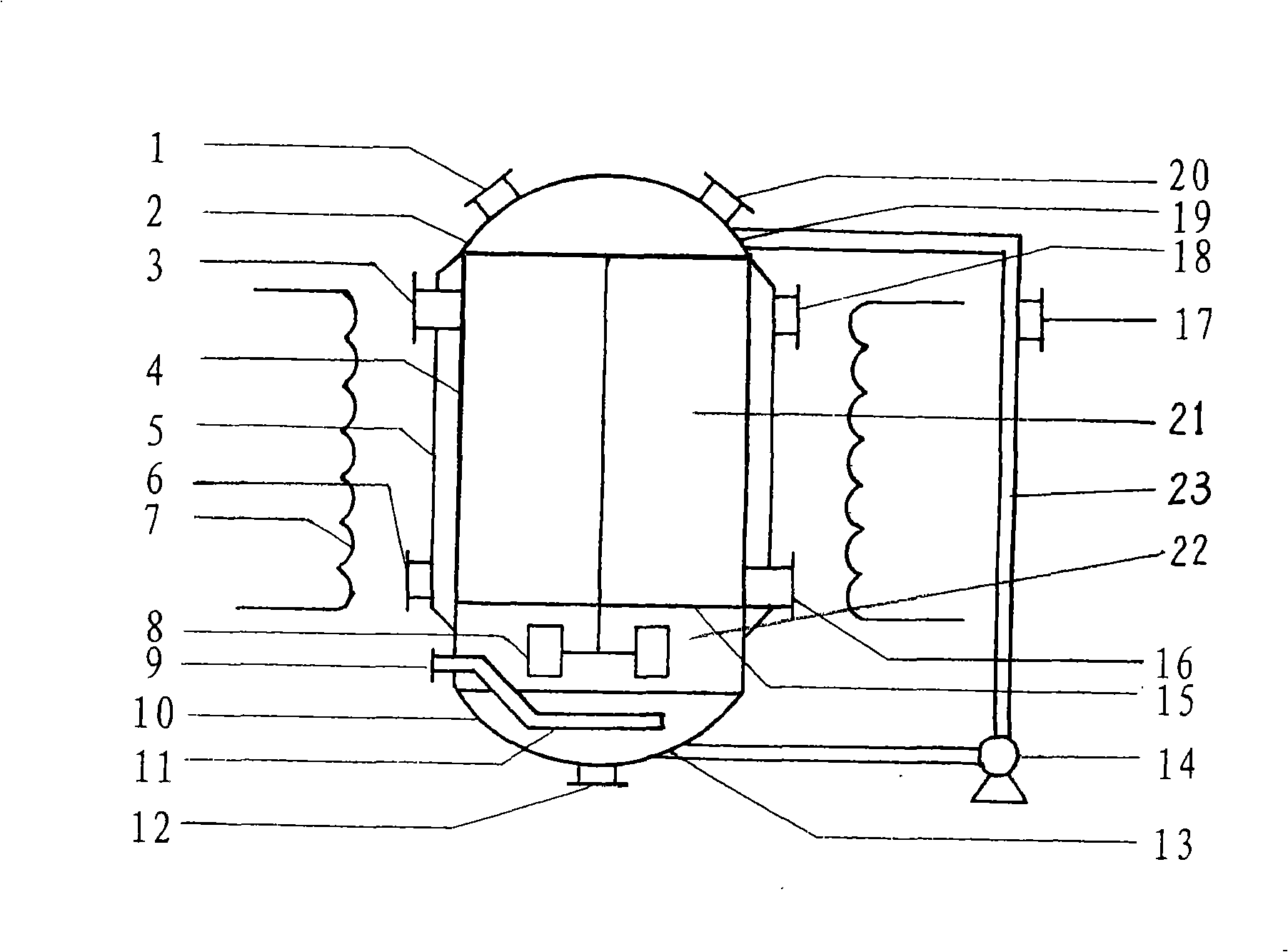

[0031] The specific implementation of the reactor for the biological oxidation of refractory gold sulfide ore according to the present invention will be given below in conjunction with the accompanying drawings.

[0032]A new reactor for bio-oxidation of refractory sulfide gold ore, including upper head 2, cylinder body 4, Helmholtz coil 7, three-blade propeller agitator 8, lower head 10, gas distribution device 11, sieve plate 15, and liquid circulation pipeline 23; an air outlet 1 and a manhole 20 are provided on the upper head 2, and a liquid outlet 12 is provided at the bottom of the lower head 10; the sieve plate 15 is located above the three-blade propeller agitator 8, Below the mineral particle outlet 16, the cylinder body 4 is divided into upper and lower parts, the upper part is the magnetically stable reaction zone 21, the lower part is the gas saturation zone 22, and the sieve plate 15 has an opening ratio between 0.4% and 1.4%. The gas-saturated liquid in the gas-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com