A ferritic stainless steel wire and wire rod excellent in corrosion resistance, cold-rolling ability and toughness having reduced surface defects and magnetic property

A technology of cold workability and corrosion resistance, applied in the field of magnetic stainless steel wire or steel wire with excellent corrosion resistance, cold workability and toughness, which can solve problems such as thermal bonding defects, high stainless steel wire, and inability to manufacture cheaply. To achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

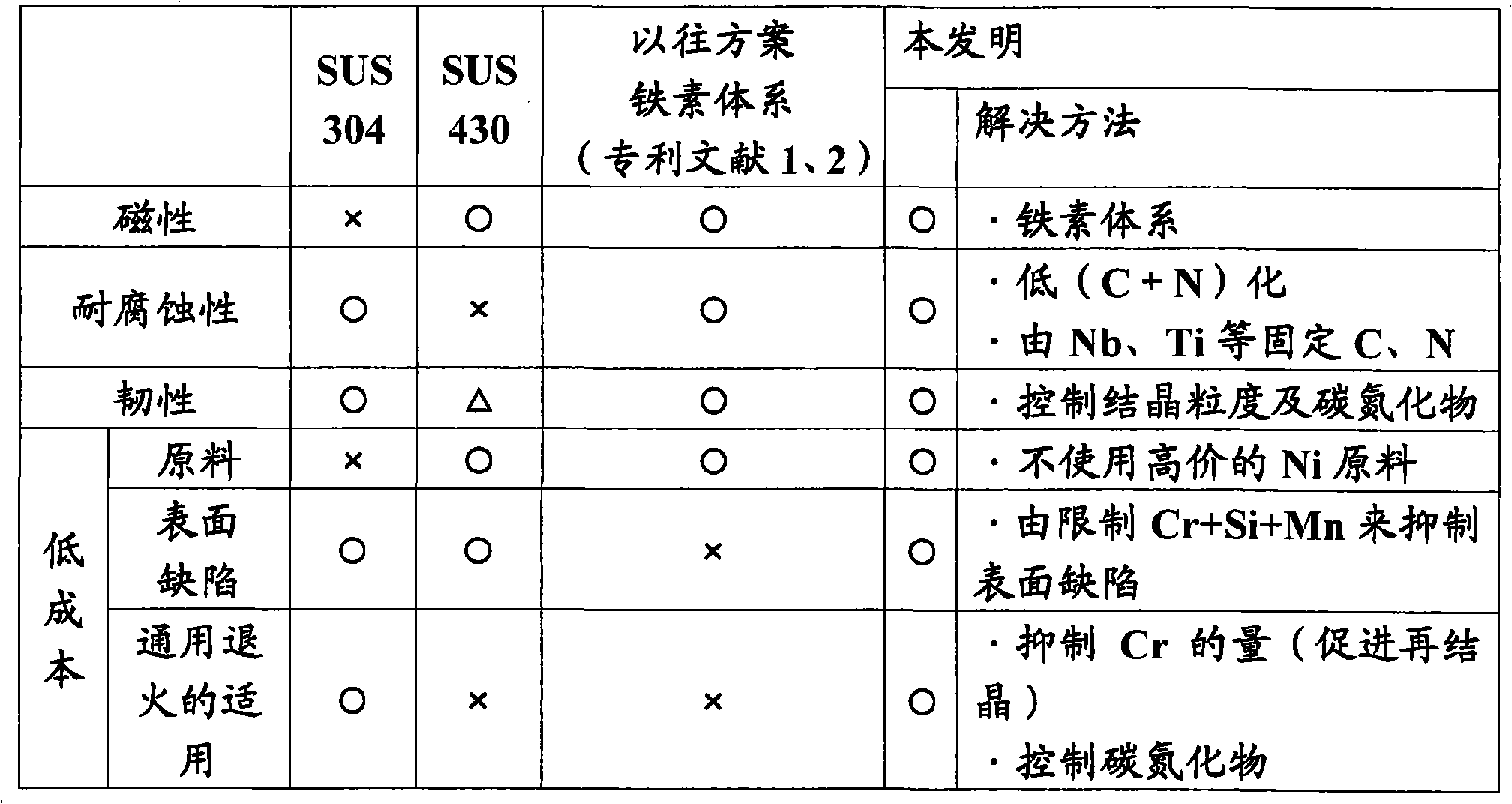

Problems solved by technology

Method used

Image

Examples

Embodiment

[0057] Embodiments of the present invention will be described below.

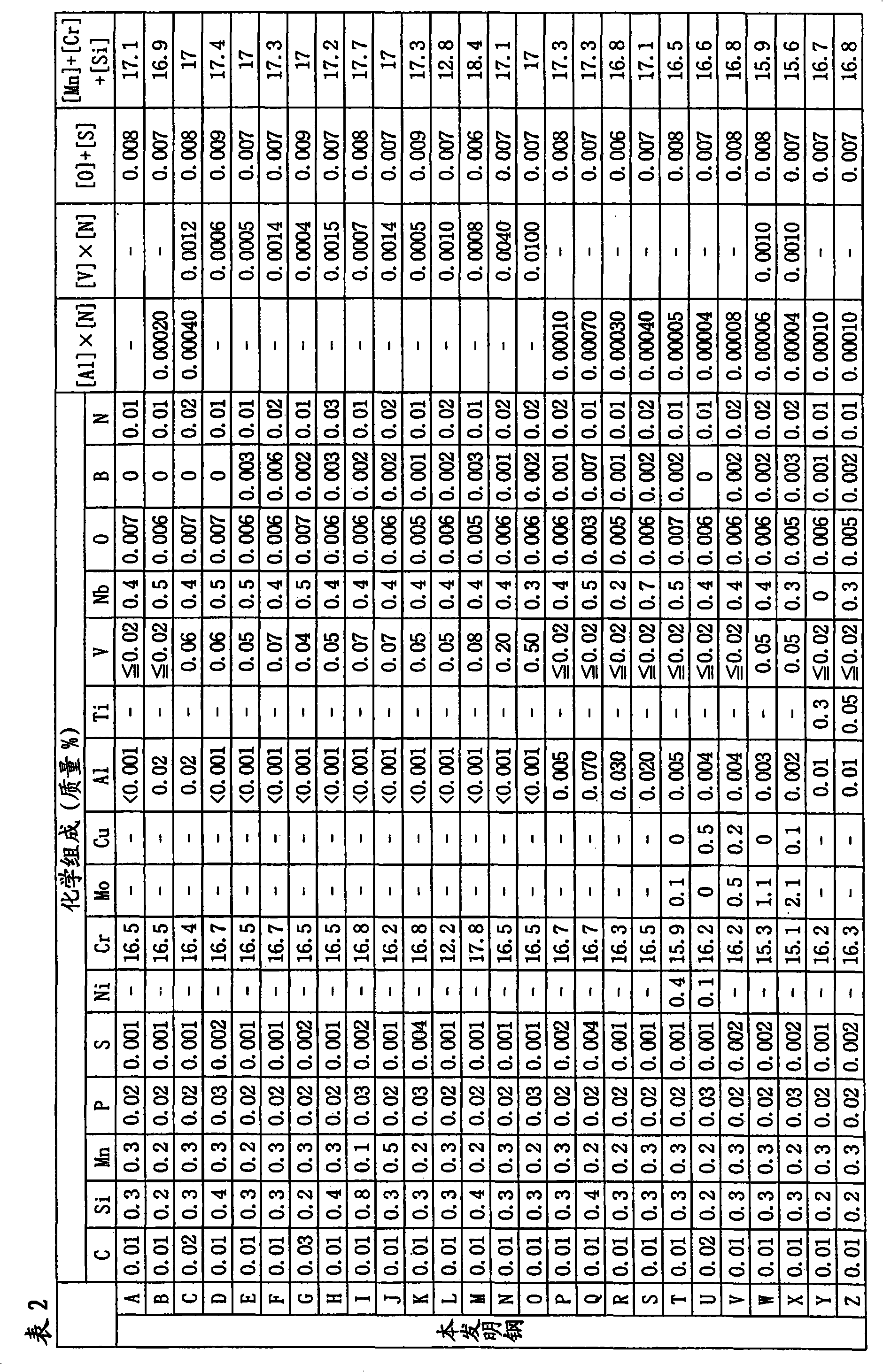

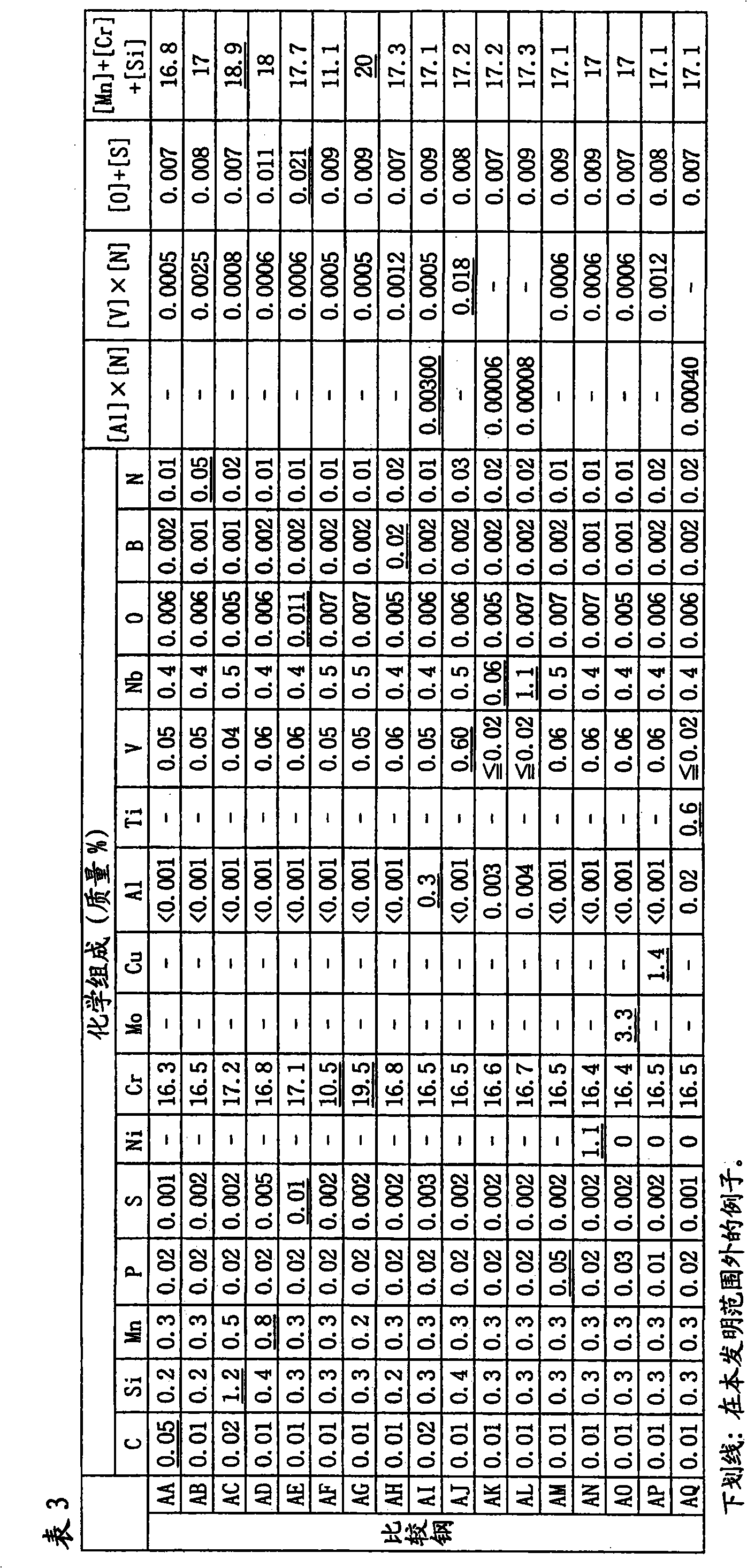

[0058] Table 2 and Table 3 show the chemical compositions of the steels of the examples of the present invention and the steels of the comparative examples.

[0059]

[0060]

[0061] The steels with these chemical compositions are melted in a 100kg vacuum melting furnace and cast into a 180mm slab. The slab is hot rolled into a wire rod until Φ5.5mm, and the hot rolling is completed at 1000°C, followed by three rounds at 1000°C. Min continuous annealing, cooling to room temperature with water cooling. Furthermore, pickling was performed to investigate surface defects. Then, cold wire drawing to Φ3.85 mm is performed.

[0062] Then, strand annealing (bright annealing, rapid cooling) was carried out at 1050°C (temperature performed in austenitic stainless steel wire), and cold workability (forging workability), toughness, corrosion resistance, and grain size were investigated. The results are shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com