Ultrasound suspending field visualized measurement method and its measuring systems

A technology of measurement system and measurement method, which is applied to measurement devices, measurement of ultrasonic/sonic/infrasonic waves, optics, etc., can solve problems such as low sensitivity, complicated measurement process, and non-adjustable measurement range, and achieve high precision, intuitive measurement results, The effect of simple and fast data processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

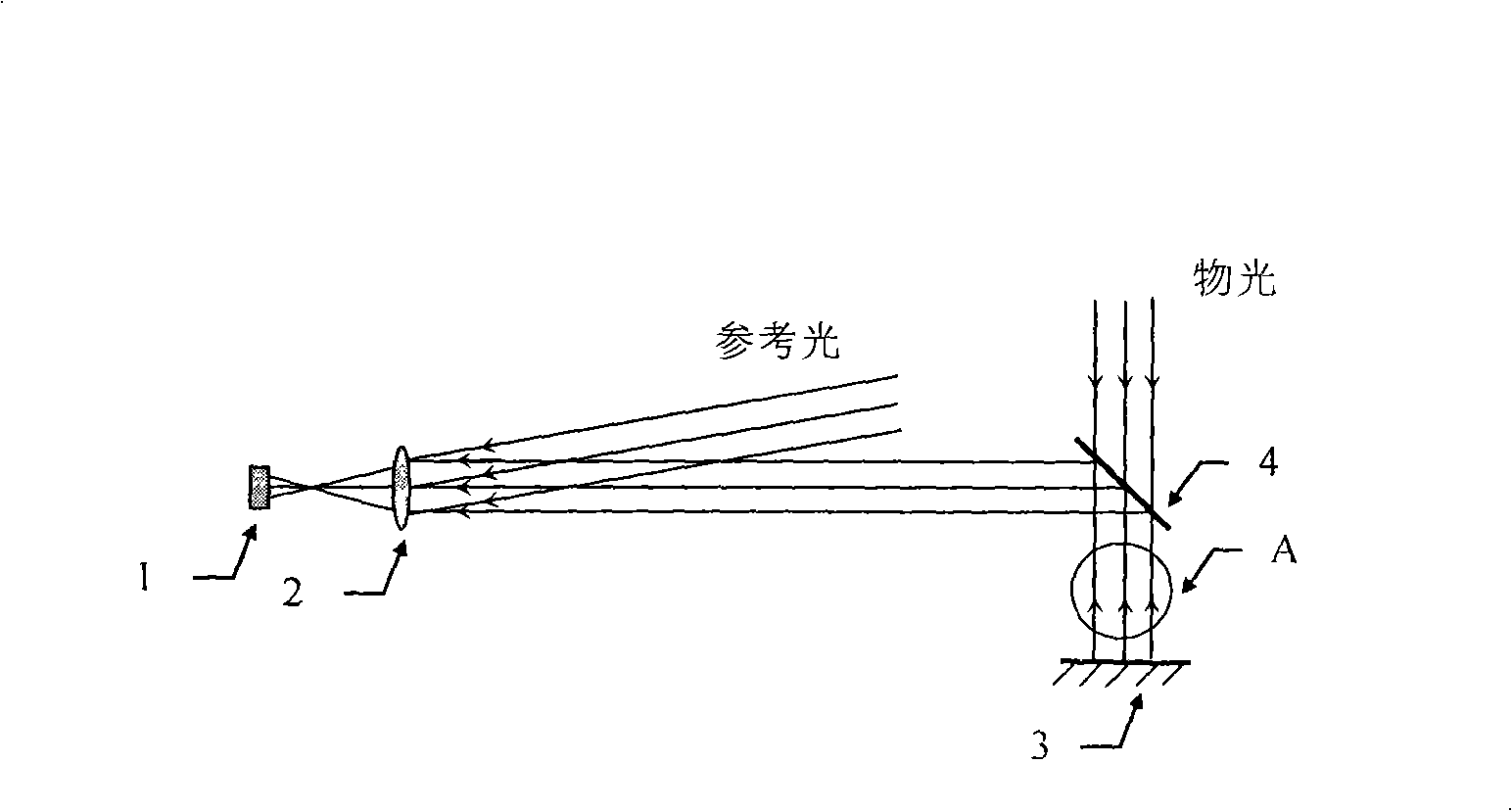

Method used

Image

Examples

Embodiment 1

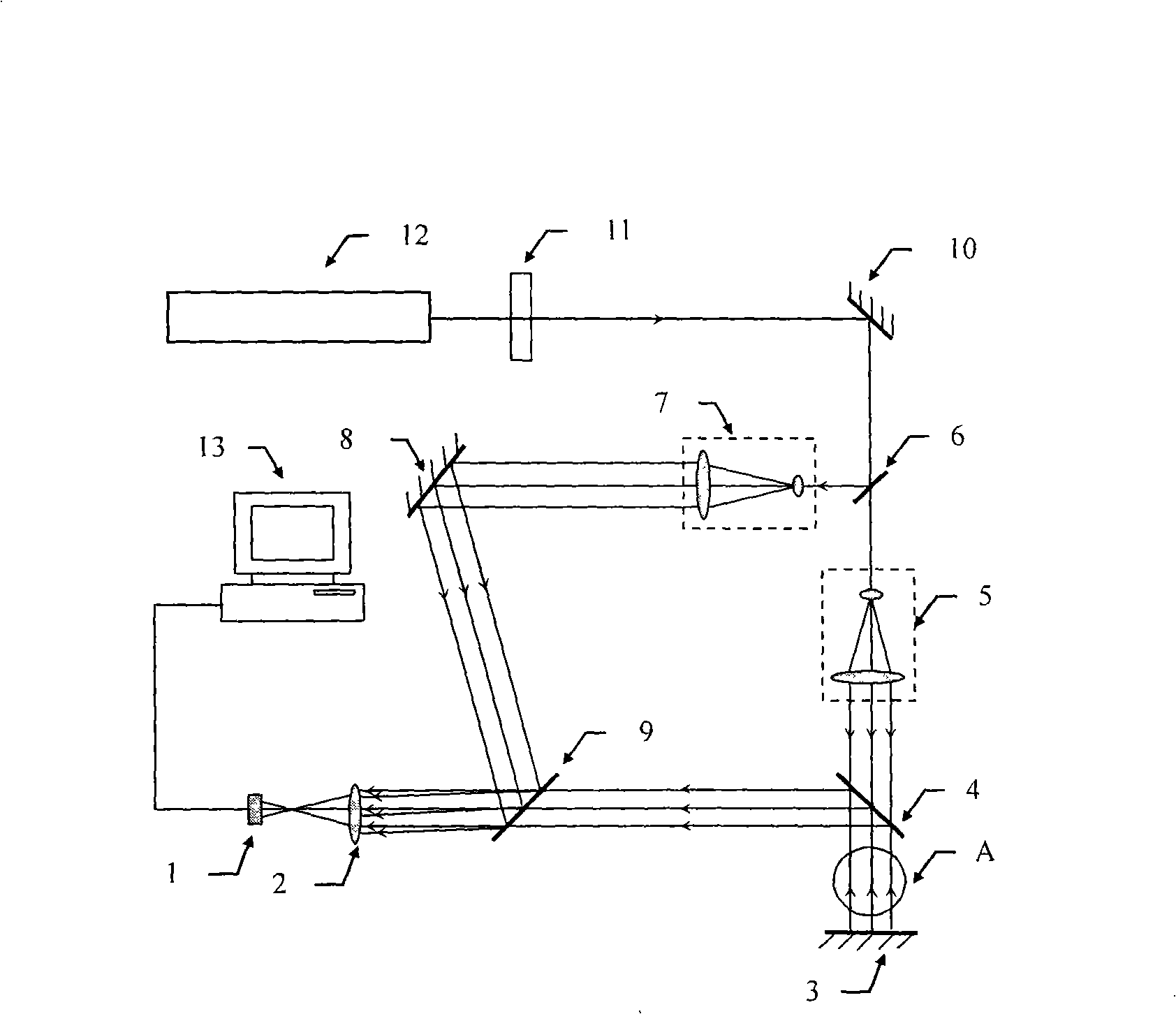

[0028] Embodiment 1: as figure 2 The shown measurement system includes a gas laser 12, an attenuator 11, a total reflection mirror 10, a beam splitter 6, a beam expander collimator 5, a half mirror 4, a total reflection mirror 3, a beam expander collimator 7, The total reflection mirror 8, the half mirror 9, the convex lens 2, the area array CCD1, and the ultrasonic field A to be measured contained therein.

[0029] The attenuator 11 is an adjustable optical attenuator, which is arranged on the optical path of the light beam emitted by the gas laser 12, and plays a role of attenuating the light intensity in order to prevent the image formed on the CCD from being too bright. The total reflection mirror 10 reflects the attenuated light to the beam splitter 6, and the beam splitter 6 is a beam splitter with an adjustable splitting ratio, and splits the beam into a first beam and a second beam. The first light beam is expanded and collimated by the beam expander and collimator 5...

Embodiment 2

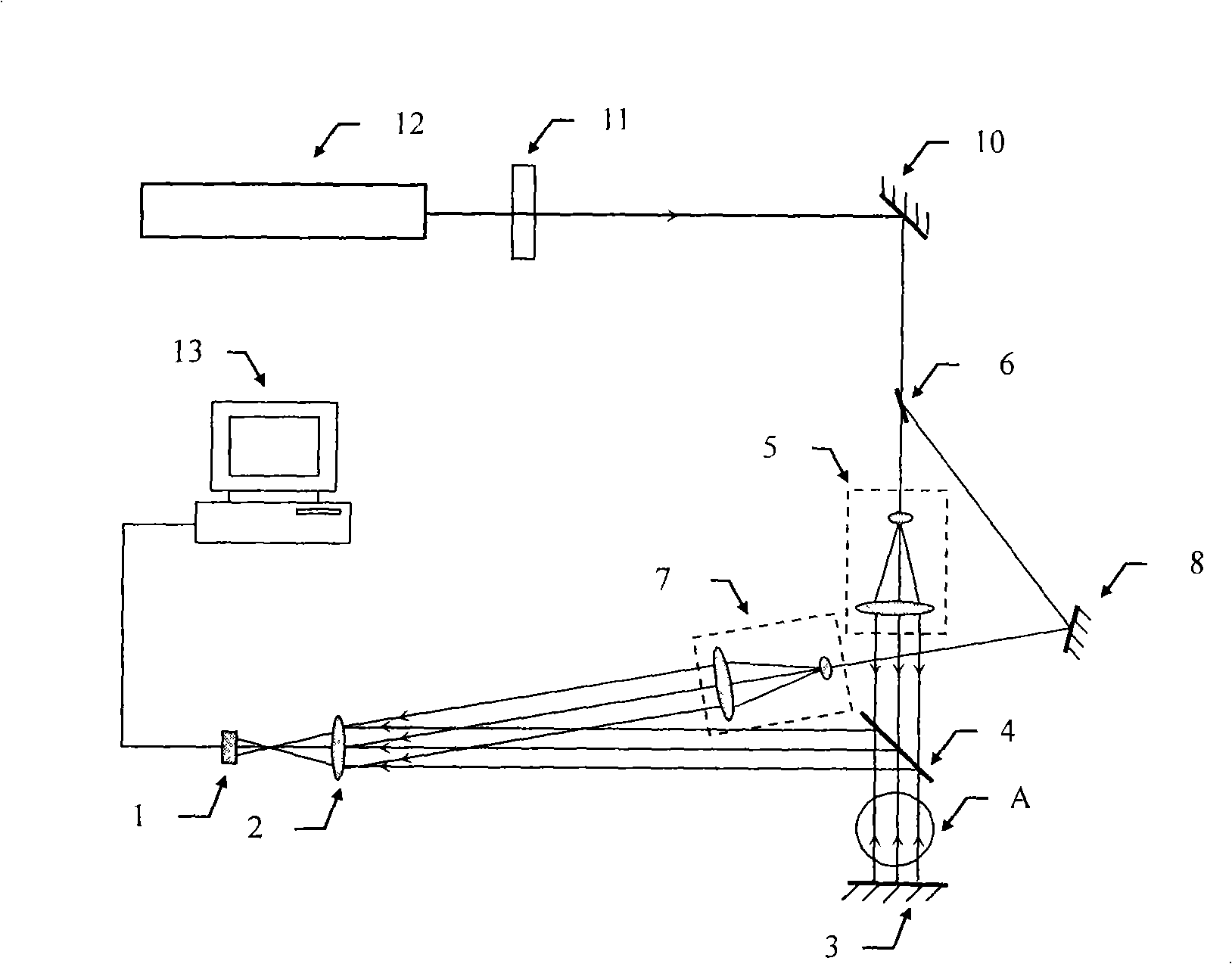

[0036] Example 2 as image 3 Shown: including gas laser 12, attenuator 11, total reflection mirror 10, beam splitter 6, beam expander collimator 5, half mirror 4, ultrasonic field to be measured A, total reflection mirror 3, beam expander collimator Straightener 7, total reflection mirror 8, convex lens 2 and area array CCD1.

[0037] In this embodiment, the half-mirror 9 is removed on the basis of the first embodiment, thereby simplifying the system. The main working process of the mode is basically the same as that of the first embodiment.

Embodiment 3

[0038] Example 3 as Figure 4 Shown: including semiconductor laser 16, attenuator 11, total reflection mirror 10, beam splitter 6, beam expander collimator 5, half mirror 4, ultrasonic field A to be measured, total reflection mirror 3, convex lens 14, Convex lens 15, beam expander collimator 7, total reflection mirror 8, half mirror 9, convex lens 2 and area array CCD1.

[0039] In this embodiment, on the basis of the first embodiment, an inverted telescope system consisting of a convex lens 14 and a convex lens 15 is added between the half mirror 4 and the half mirror 9 in the first optical path. The main working process is basically the same as that of the first embodiment, the difference is that in the main working process of the third embodiment, due to the addition of the inverted telescope system, the measurement system can adapt to the larger area of the ultrasonic field to be measured , Beyond the acceptable range of CCD.

[0040] During the working process, when t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com