Tooth geometrical shape measurement device

A technology of geometric shape and measuring device, applied in the directions of diagnostic recording/measurement, dentistry, medical science, etc., can solve the problems of reducing the resolution of digital images of teeth, highly blurred digital images of teeth, and uncertainty of digital image data, etc. Achieve improved measurement sensitivity and accuracy, shadow avoidance, high mesh geometry image resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

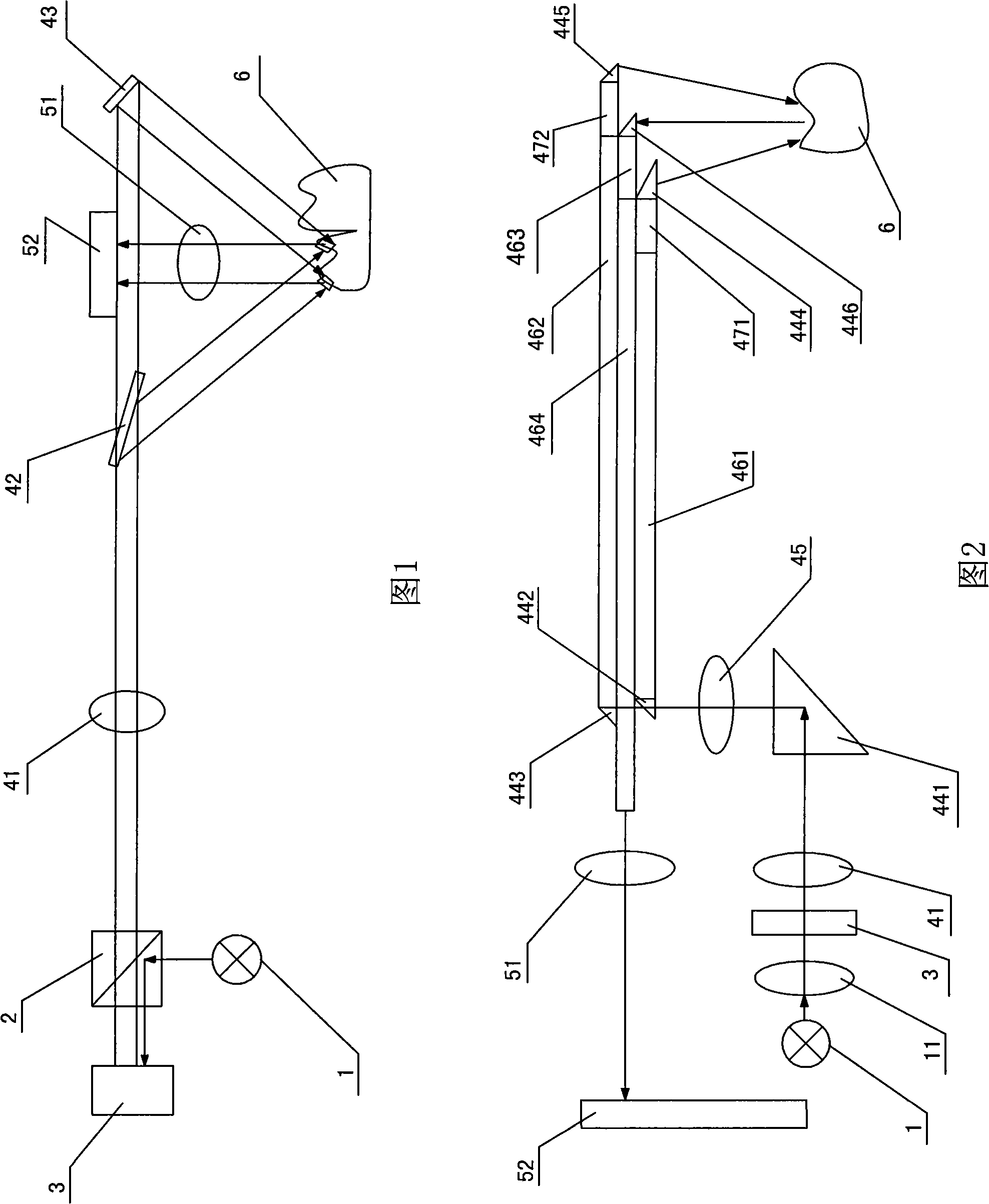

[0019] Embodiment one: as shown in Figure 1, a kind of tooth geometry measuring device, this device comprises light source 1, image generation unit, projection unit and imaging unit; Image generation unit comprises the programmable pattern generator 3 and polarization Dichroic prism 2, the projection unit includes projection lens 41, variable polarization beam splitter 42 and reflector 43, variable polarization beam splitter 42 and reflector 43 are distributed on both sides of the imaging unit, and the imaging unit includes imaging lens 51 and imaging camera 52 , the incident light emitted by the light source 1 is irradiated on the programmable pattern generator 3 through the polarizing beam splitter prism 2, and the programmable pattern generator 3 generates a mesh geometric pattern image, and outputs the polarized mesh geometric pattern image through the polarizing beam splitter prism 2, and then The polarized mesh geometric image is transmitted to the variable polarization b...

Embodiment 2

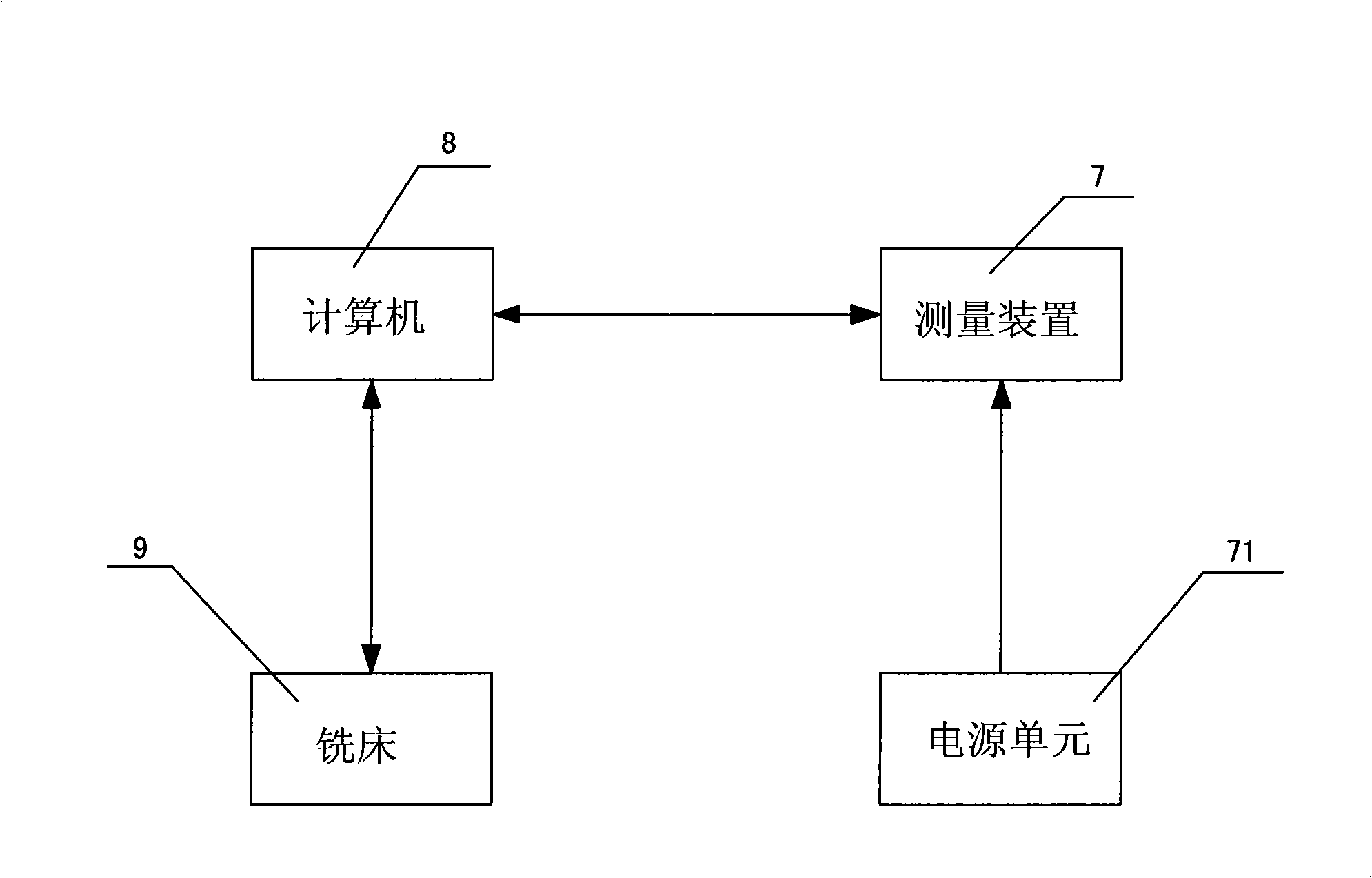

[0025] Embodiment two: as shown in Figure 2, the difference between this embodiment and embodiment one is only that the image generation unit includes a programmable pattern generator 3 connected to an external computer, and the light source 1 and the programmable pattern generator 3 are provided with The illumination lens 11, the projection unit includes a projection lens 41, a first prism 441, a scanning lens 45, a second prism 442, a third prism 443, a first gradient lens 461, a second gradient lens 462, a first gradient lens objective lens 471, a fourth gradient lens Prism 444, the second gradient lens objective lens 472 and the fifth prism 445, the imaging unit includes the sixth prism 446, the third gradient lens 463, the fourth gradient lens 464, imaging lens 51 and imaging camera 52, the second prism 442 is a polarization splitter Prism; the incident light emitted by the light source 1 is irradiated on the programmable pattern generator 3 through the illumination lens 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com