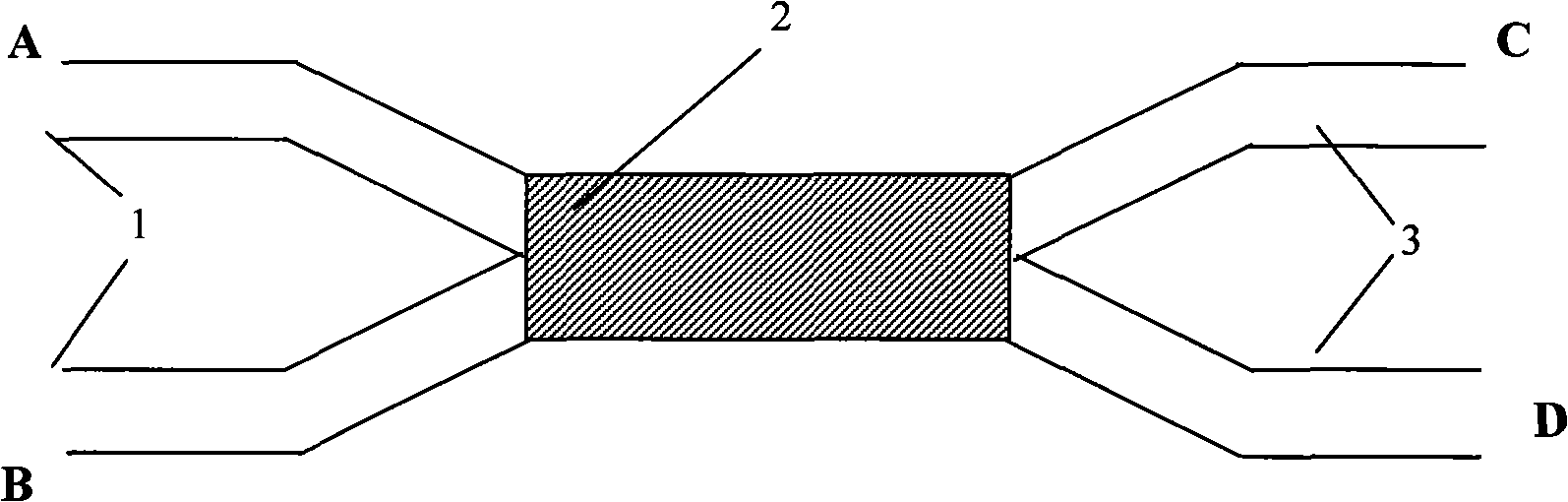

Light circulator based on space-free directional coupled structure

A technology of directional coupling and optical circulator, which is applied in the coupling direction of optical waveguide, etc., can solve the problems that the device has not been developed, and achieve the effect of compact structure and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

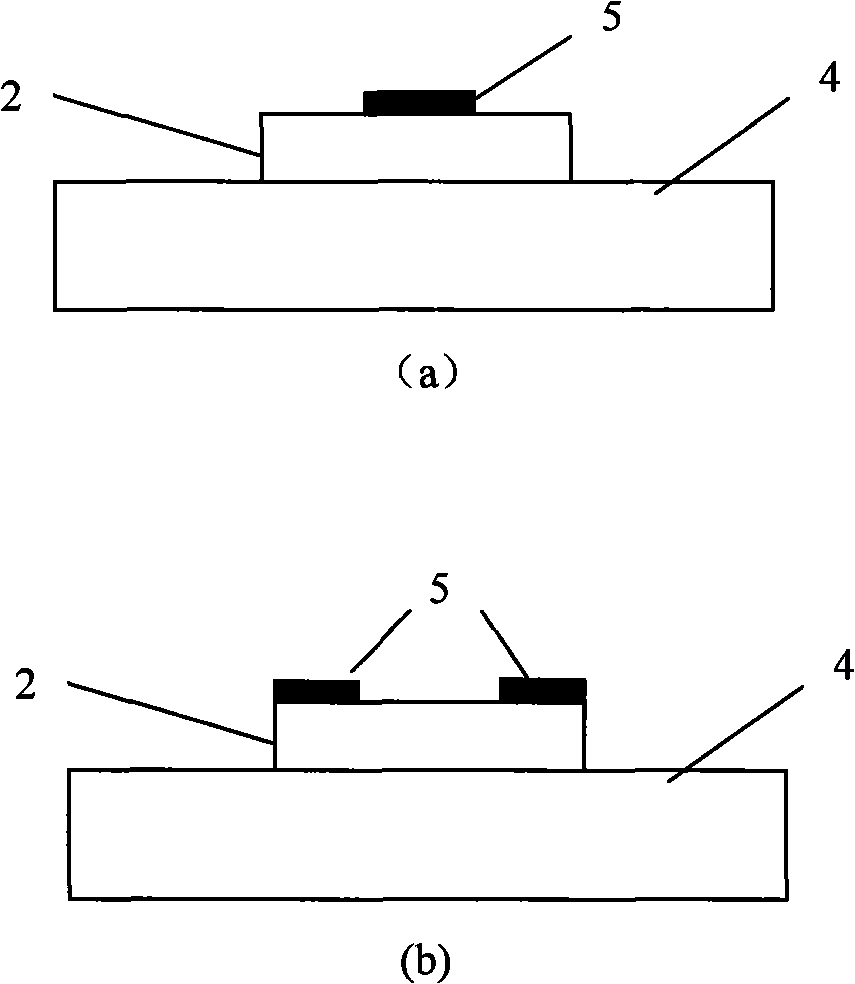

[0031] In the manufacture of devices, a layer of non-magnetic metal film or dielectric film is grown on the dielectric substrate, and then the rectangular dual-mode waveguide is fabricated by chemical wet etching or reactive ion etching, and then the rectangular dual-mode waveguide is used on the rectangular dual-mode waveguide area. Local bonding or sputtering methods to prepare centers (eg figure 2 (a)) or central symmetry (such as figure 2 As shown in (b), a magnetic material thin film 5 is provided.

Embodiment 2

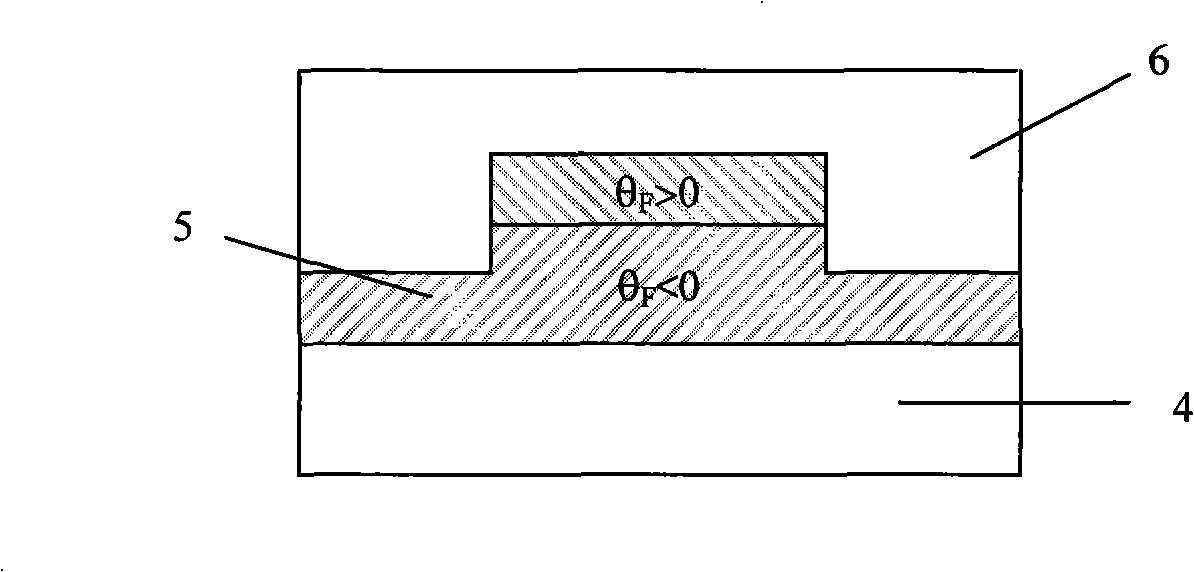

[0033] A thin film of magnetic material is grown on the substrate, and then the waveguide is fabricated by chemical wet etching or reactive ion etching, and a cladding layer 6 with a large difference in refractive index from the substrate can also be grown on it, such as image 3 shown.

[0034] In order to enhance the non-reciprocal phase shift and realize more compact optical isolators and optical circulators, it is also possible to use another layer of Faraday rotation coefficient θ on the magnetic material film F On the contrary, a thin film of magnetic material is used to fabricate a waveguide by chemical wet etching or reactive ion etching. like image 3 The Faraday rotation coefficient θ shown in F >0 at the Faraday rotation coefficient θ F F F >0 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com