Container transportation method

A transportation method and container technology, applied in the direction of transportation and packaging, conveyors, roads, etc., can solve problems such as unsuitable for large-scale container transportation, shortage of transportation facilities, and greater impact of weather, so as to reduce energy consumption and exhaust emissions, Reduces traffic accidents and has good earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

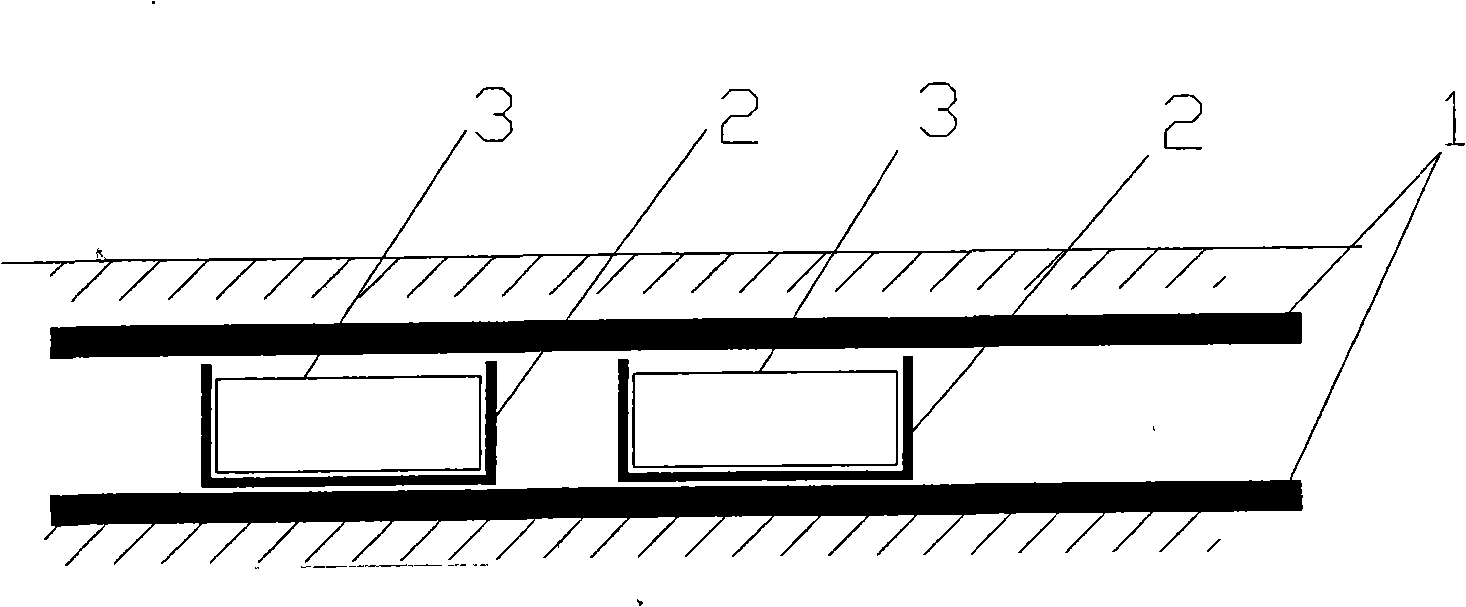

[0015] Using underground single circular tunnels or pipelines (see figure 1 ), the carrier adopts unmanned automatic guided vehicles to reduce the environmental requirements for underground tunnels or pipelines, reduce the cost, shorten the construction period, and at the same time improve efficiency and safety. The unmanned automatic guidance described here The car is a prior art, so it does not repeat its working principle here, and each carrying device should be able to transport more than two 20-foot standard containers or more than one 40-foot container. During transportation, the container at the port is lifted first and then placed in the container; then the unmanned automatic guided vehicle passes through the underground single-circle tunnel or pipeline to the freight terminal according to the set route, and then the unmanned automatic guided vehicle travels along the freight terminal The slope reaches the ground; finally, the containers on the carrier are sorted and l...

Embodiment 2

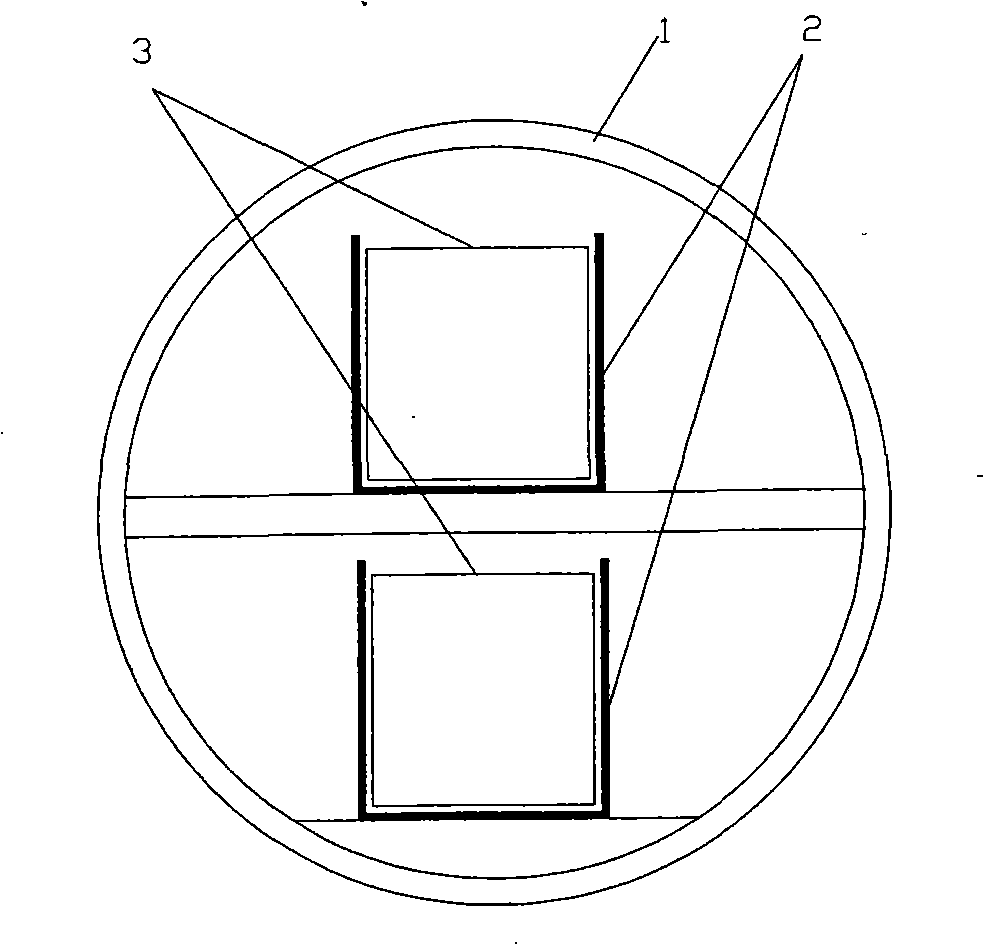

[0017] Lift the container in the port and place it in the automatic rail locomotive; the automatic rail locomotive passes through the underground tunnel or pipeline with left and right transport lanes according to the set route (see figure 2 and image 3 ) arrives at the freight terminal, where the underground tunnel or pipeline is provided with tracks, guides and monitoring devices that match the automatic rail locomotive (these are all prior art, so it will not repeat its working principle), and then the automatic rail locomotive Along the slope of the freight terminal to the ground, there is a track on the slope that matches the automatic rail locomotive; finally, the containers on the automatic rail locomotive are sorted and lifted to complete loading and unloading, and the loaded and unloaded containers are finally transported to the destination by the conveyor belt.

Embodiment 3

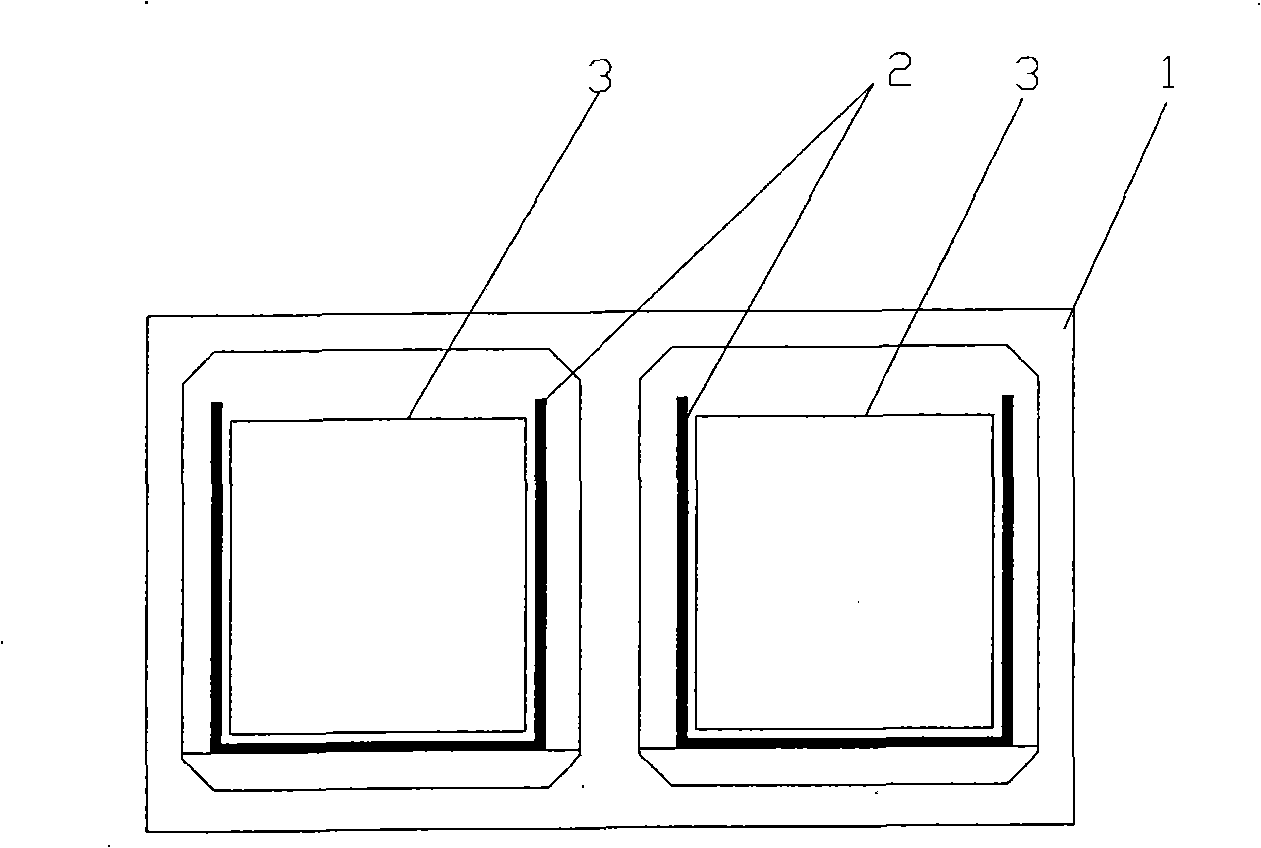

[0019] Lift the container in the port and place it in the automatic rail locomotive; the automatic rail locomotive passes through the underground tunnel or pipeline with upper and lower transport layers according to the set route (see Figure 4 , the height and width of each transport layer are greater than the height and width of the automatic rail locomotive, and the smaller caliber is used as much as possible to reduce the cost) to the freight terminal, where the underground tunnel or pipeline is equipped with an automatic rail locomotive The matching track, guiding device and monitoring device, and then the automatic rail locomotive reaches the ground along the slope of the freight terminal, and the track and traction rope matching the automatic rail locomotive are provided on the slope; finally, the containers on the automatic rail locomotive are sorted, lifted and Complete loading and unloading. When implementing, it can start with the areas with the most serious congest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com