Novel electrolytic degreasing bath

A technology of electrolytic degreasing and degreasing tank, which is applied in the production of electrolytic degreasing and surface treatment production. It can solve the problems of difficult cleaning of solid dirt deposits, inability to fully stir the electrolyte, and inability to quickly remove small air bubbles, so as to reduce the removal of solid dirt. The effect of increasing the number of times of material, uniformity of electrolyte, and the qualified rate of coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

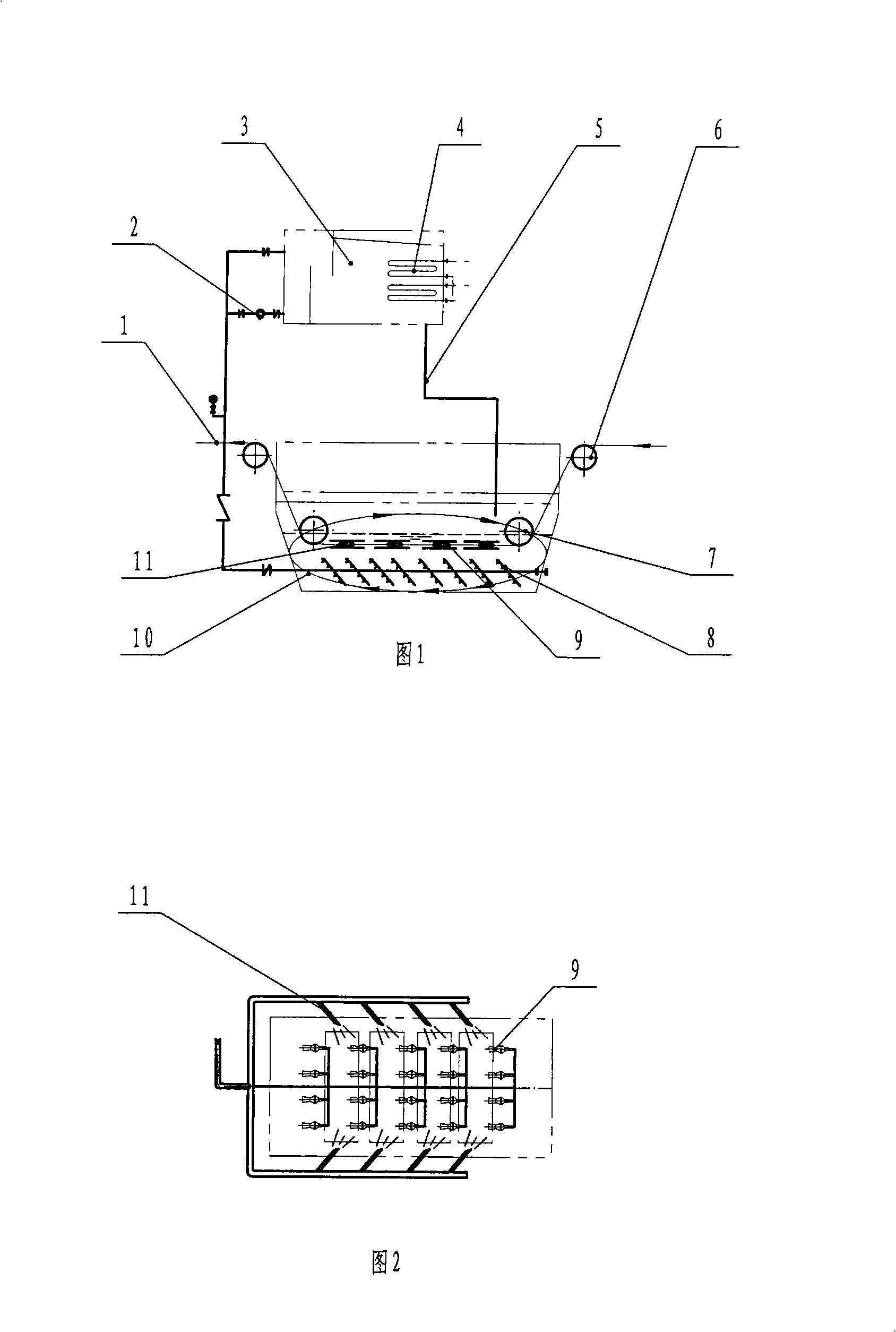

[0011] As shown in accompanying drawing 1: the centrifugal pump 2 that provides power for the circulation of the electrolyte transports the electrolyte from the circulation tank 3 through the mixed flow nozzle 8 and the mixed flow nozzle 11 to the electrolytic degreasing tank 10, and then passes the return pipe 5 to bring the liquid to the electrolytic degreasing tank. Returning to the circulation tank 3, the electrolyte heating coil 4 is located in the circulation tank 3 for heating the electrolyte, ensuring the temperature required for electrolysis. The two steering rollers 6 are respectively installed on the inlet side and the inlet side of the electrolytic degreasing tank 10, the sinking roller 7 is installed in the electrolytic degreasing tank 10, and the electrolyte circulation return port is opened on the steel strip inlet side to facilitate the discharge of turbid electrolyte containing impurities It will not pollute the clean strip at the outlet of the electrolyzer. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com