Method for preparing single crystal granule tungsten carbide

A technology of single crystal particles and tungsten carbide, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve problems affecting product quality, poor densification, poor thermal stability, etc., and achieve superior thermal stability , good densification and uniform carbonization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

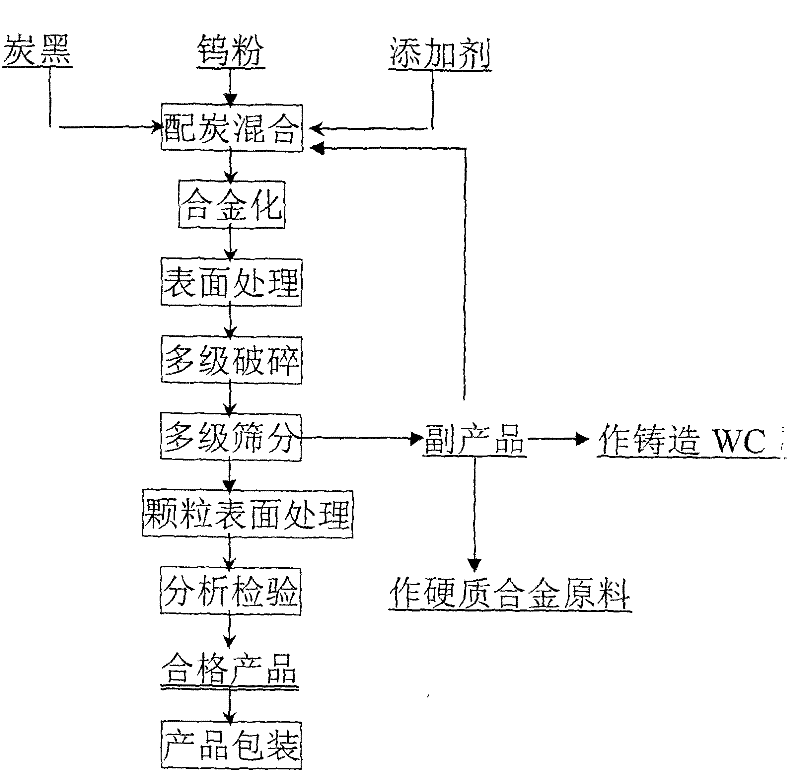

Image

Examples

Embodiment Construction

[0023] The present invention successfully develops single crystal particle tungsten carbide through the method of using additives, using the principle of chemical exothermic reaction, and high-temperature tungsten carbide and casting tungsten carbide production technology. The product quality has reached the international advanced level, and its technical indicators are as follows :

[0024] T.C: 6.08-6.20% Specific gravity: 15.4-15.6g / cm 3

[0025] F.C: 0.10% Hall flow rate: 10.5-14.5s / 50g

[0026] SCOTT (g / cm 3 ):

[0027] WC60-80 WC80-200 WC200-400

[0028] 7.0-7.6 6.8-7.2 6.0-6.6

[0029] Impurity content (not greater than):

[0030] Fe: 0.19% Si: 0.02% Mo: 0.07%

[0031] Ti: 0.15% Ta Ta: 0.03% Nb: 0.03%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com