Preparation of polyaniline nano-wire/nano-particle compound system

A nanoparticle and nanowire technology is applied in the field of preparation of polyaniline nanowire/nanoparticle composite system, which can solve the problem of polyaniline nanowire/nanoparticle composite system morphology parameters, difficult to control electromagnetic properties, oil phase organic solvent environment Pollution, template agent is not easy to remove and other problems, to achieve the effect of adjustable micro-morphological parameters, avoid environmental pollution, and great practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

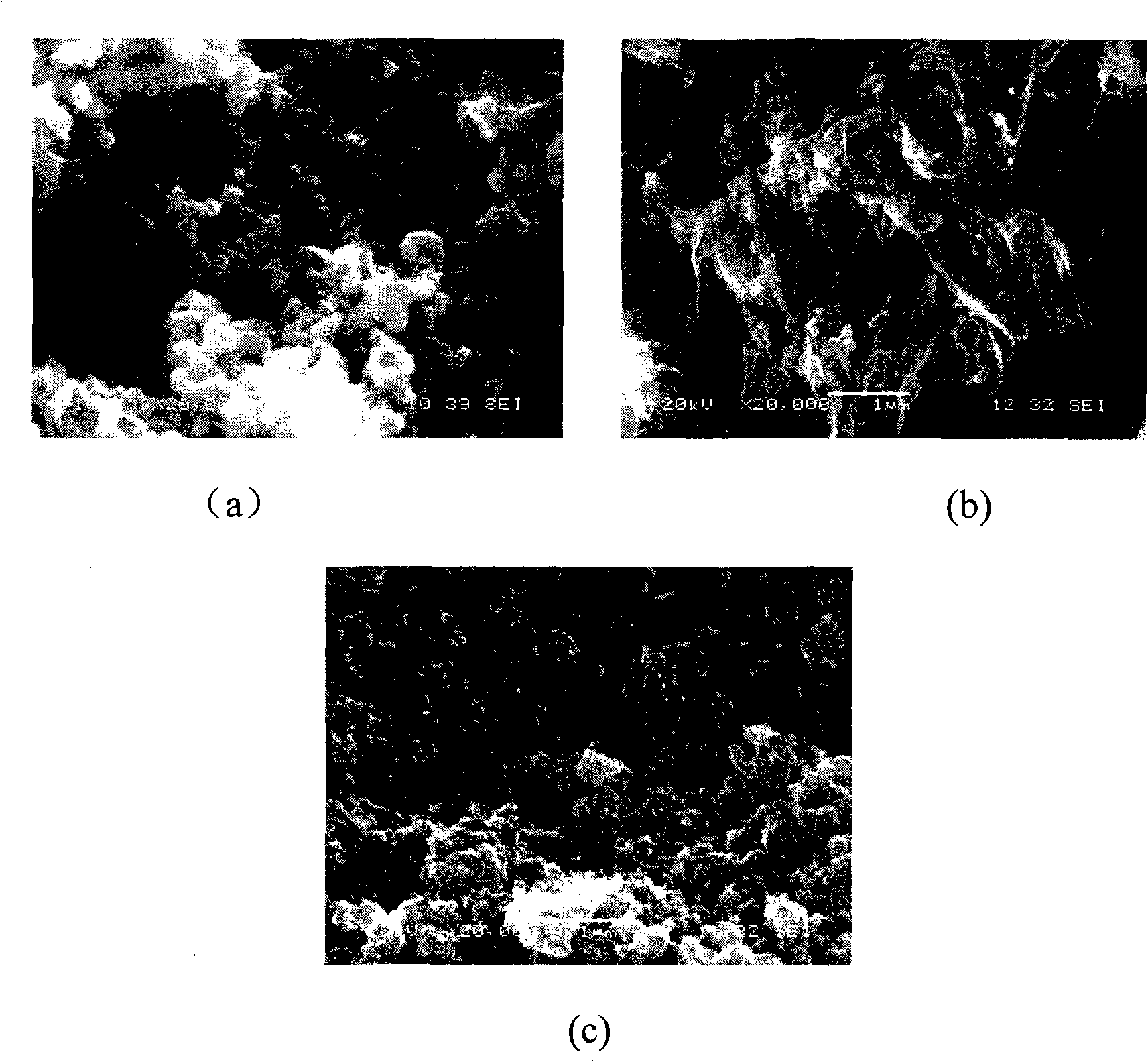

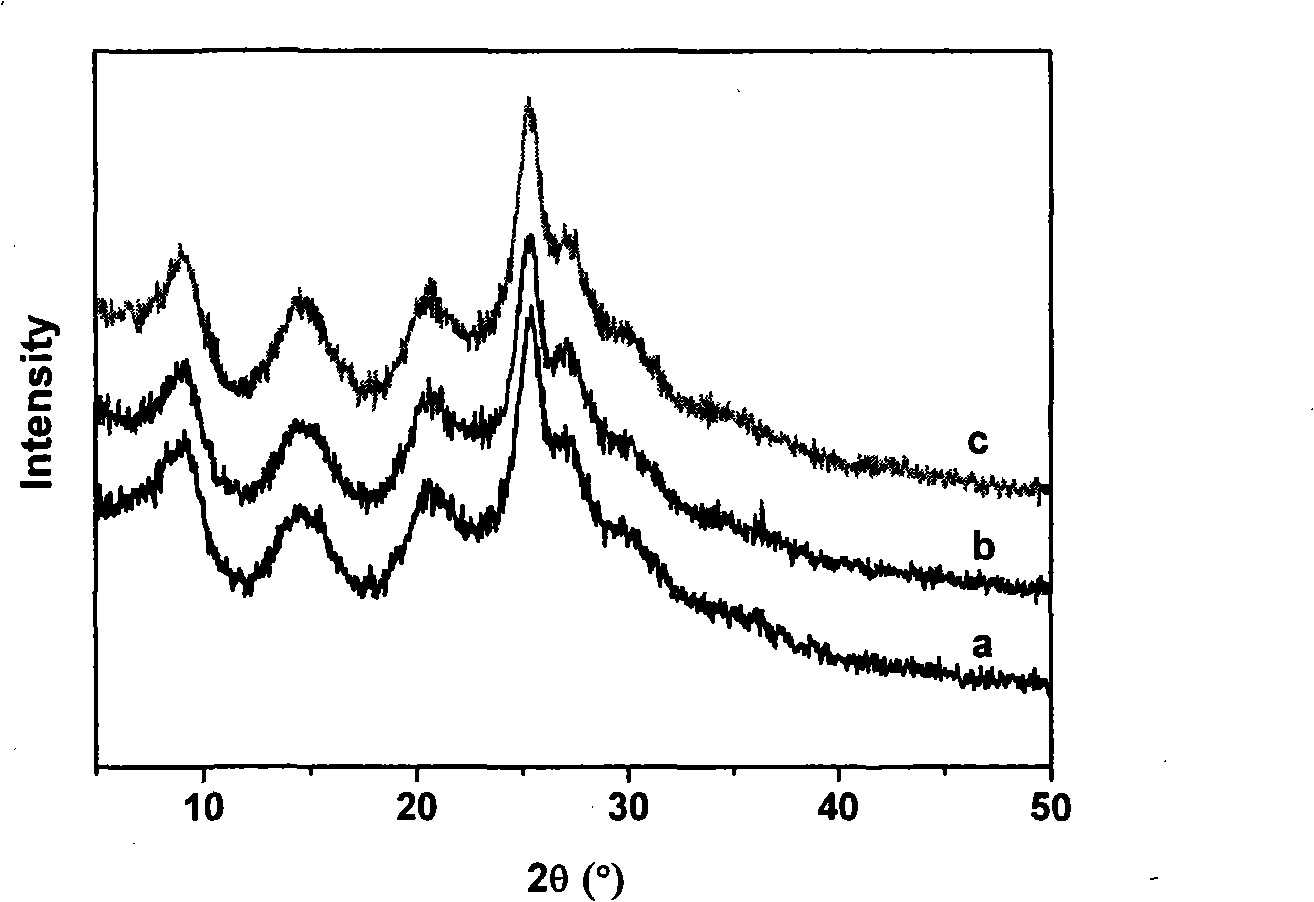

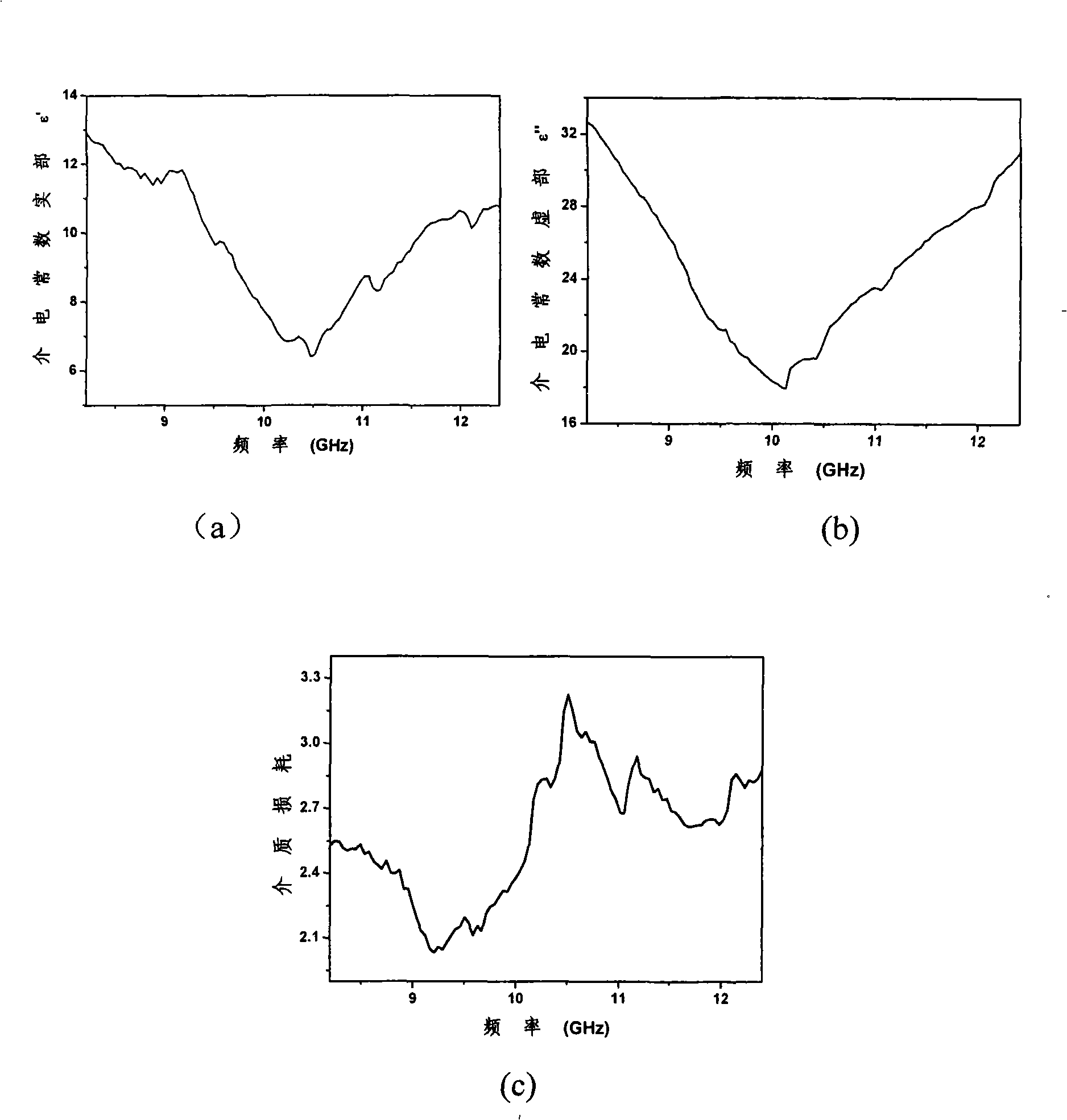

Embodiment 1

[0026] (1) 0.1 part of sucrose octaacetate is dissolved and dispersed in 30 parts of water reaction medium;

[0027] (2) Dissolve 5 parts of hydrochloric acid in the above-mentioned solution under stirring condition;

[0028] (3) Add 2 parts of aniline under stirring condition to form component A;

[0029] (4) 5 parts of ammonium persulfate are dissolved in 20 parts of water to form component B;

[0030] (5) Add component B to component A drop by drop continuously under stirring condition, the dropping rate is 1.0ml / min~5.0ml / min, after the dropwise addition, continue to react for 3~12 hours, the reaction temperature is controlled Between 0°C and 5°C;

[0031] (6) After filtering the reaction product, wash with methanol, acetone and deionized water respectively until the filtrate is colorless;

[0032] (7) carry out secondary doping with hydrochloric acid aqueous solution, the hydrochloric acid concentration that secondary doping is used is 0.5M~4.0M, and the time of doping...

Embodiment 2

[0035] (1) water and water-soluble organic solvent are mixed in a volume ratio of 1:1 to form a homogeneous system of 70 parts;

[0036] (2) Dissolving 2 parts of sucrose octaacetate in the above system;

[0037] (3) 5 parts of hydrochloric acid are dissolved in the above-mentioned solution under the condition of stirring;

[0038] (4) Add 4 parts of aniline under stirring condition to form component A;

[0039] (5) Dissolving 10 parts of ammonium persulfate in 20 parts of a homogeneous system formed by mixing water and a water-soluble organic solvent in a ratio of 1:1 by volume to form component B;

[0040] (6) Continuously add component B dropwise to component A under stirring condition, the dropping speed is 1.0ml / min~5.0ml / min; continue to react for 3~12 hours after the dropwise addition, the reaction temperature is controlled at Between 0°C and 5°C;

[0041] (7) After filtering the reaction product, wash with methanol, acetone and deionized water respectively until the...

Embodiment 3

[0045] (1) 3 parts of sucrose octaacetate are dissolved and dispersed in 100 parts of water reaction medium;

[0046] (2) Dissolve 5 parts of hydrochloric acid in the above-mentioned solution under stirring condition;

[0047] (3) Add 2 parts of aniline under stirring condition to form component A;

[0048] (4) 5 parts of ammonium persulfate are dissolved in 20 parts of water to form component B;

[0049] (5) Add component B to component A drop by drop continuously under stirring condition, the dropping rate is 1.0ml / min~5.0ml / min, after the dropwise addition, continue to react for 3~12 hours, the reaction temperature is controlled Between 0°C and 5°C;

[0050] (6) After filtering the reaction product, wash with methanol, acetone and deionized water respectively until the filtrate is colorless;

[0051](7) carry out secondary doping with hydrochloric acid aqueous solution, the hydrochloric acid concentration that secondary doping is used is 0.5M~4.0M, and the time of doping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com