Cast-in-situ light composite wall

A composite wall and lightweight technology, applied to walls, building components, buildings, etc., can solve problems such as poor thermal insulation effect, complicated construction methods, poor thermal insulation performance, etc., achieve good sound insulation effect, simplify construction procedures, and Good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

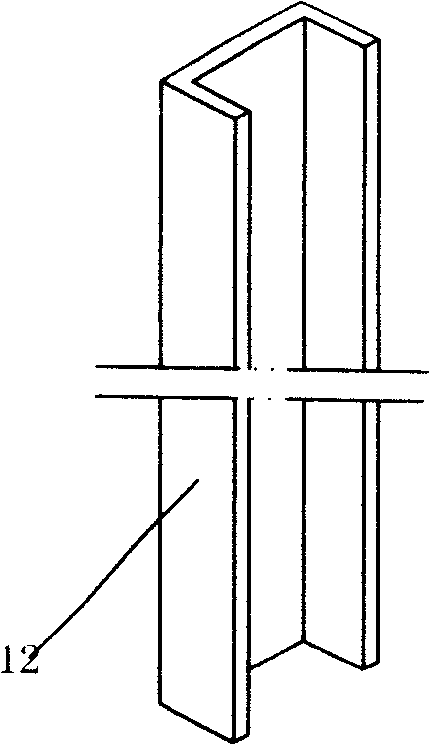

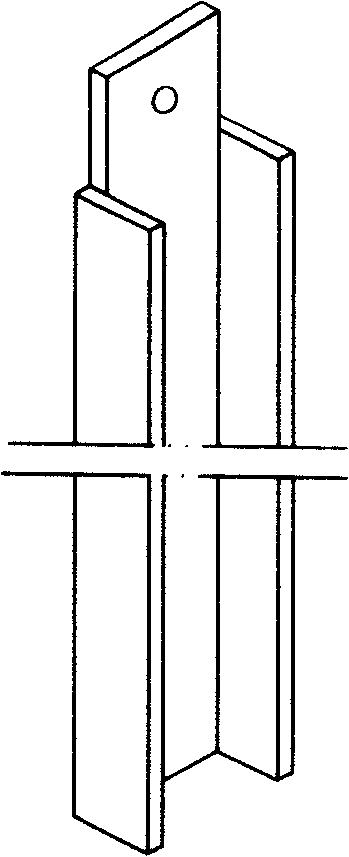

[0021] In order to clearly illustrate the present invention, the size of each component in the drawings is different from the actual size; among them, the size of some components is completely different from the actual use, and is displayed in an enlarged state, the purpose of which is to show the composition of the component more clearly .

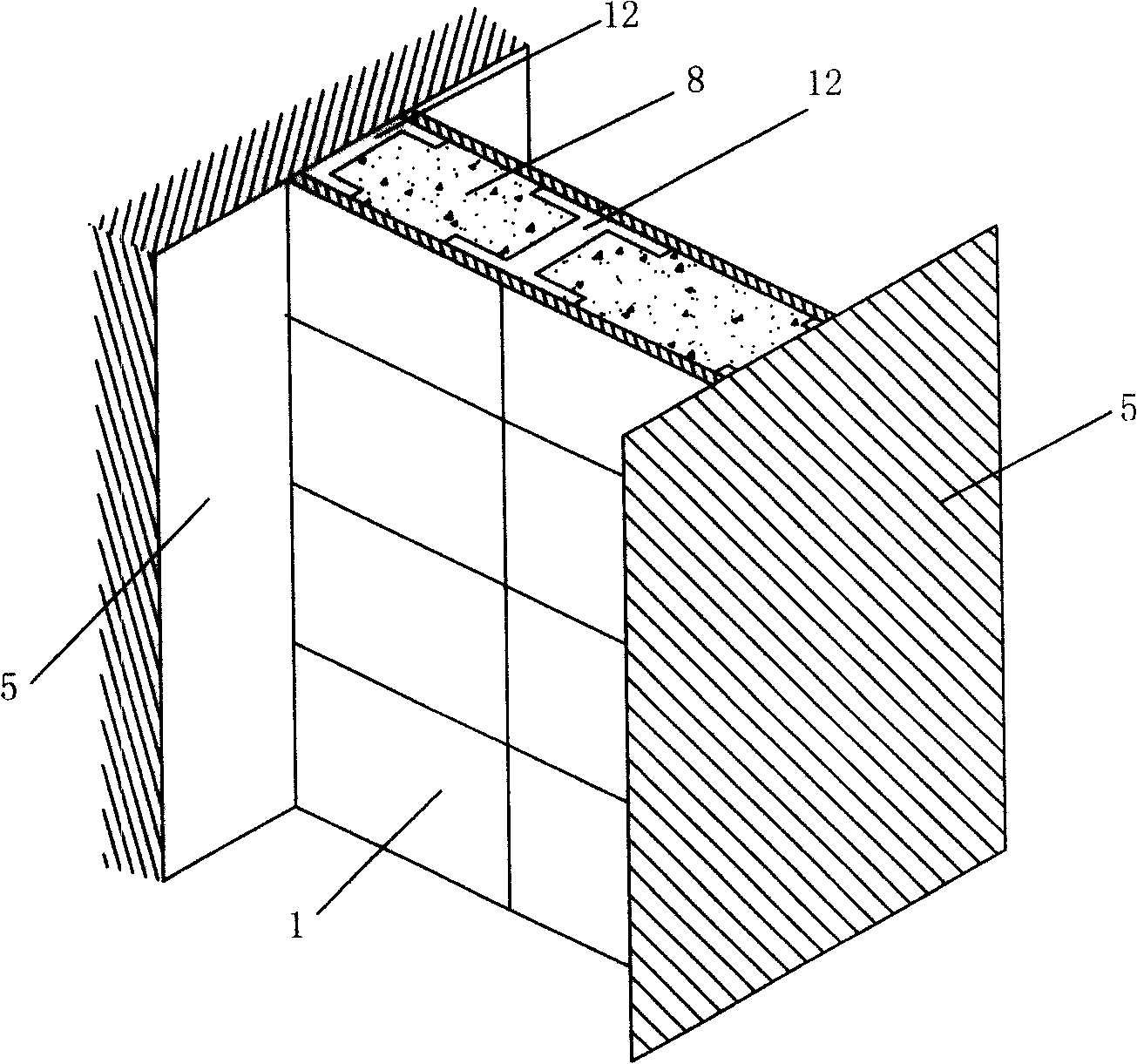

[0022] like figure 1 As shown, the cast-in-place composite wall of the present invention includes wall surfaces assembled by prefabricated wall panels 1 on both sides, and a lightweight concrete interlayer 8 between the prefabricated wall panels 1 . The prefabricated wall panels 1 are made using fiber cement or concrete. In order to ensure the distance between the prefabricated wall panels on both sides, and at the same time strengthen the strength of the wall to facilitate wall construction, light steel keels 12 are arranged at intervals between the prefabricated wall panels 1 . In the preferred mode, the light steel keel is supported ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap