Electric plasticization drive method and apparatus based on direct back-pressing feed back control

A feedback control, electric technology, applied in the field of electric plasticizing drives and devices with direct back pressure feedback control, can solve problems such as high cost, and achieve the effects of low cost, convenient processing and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The electric plasticizing unit in the electro-hydraulic composite injection molding machine adopts the direct back pressure feedback control method proposed by the present invention to design the electric plasticizing driving device. Metering / plasticizing and injection are all driven by servo motors, mold opening and closing are driven by electro-hydraulic composite mechanism, mold moving is driven by motor, and mold clamping is driven by hydraulic pressure, which can achieve high precision and energy saving effect.

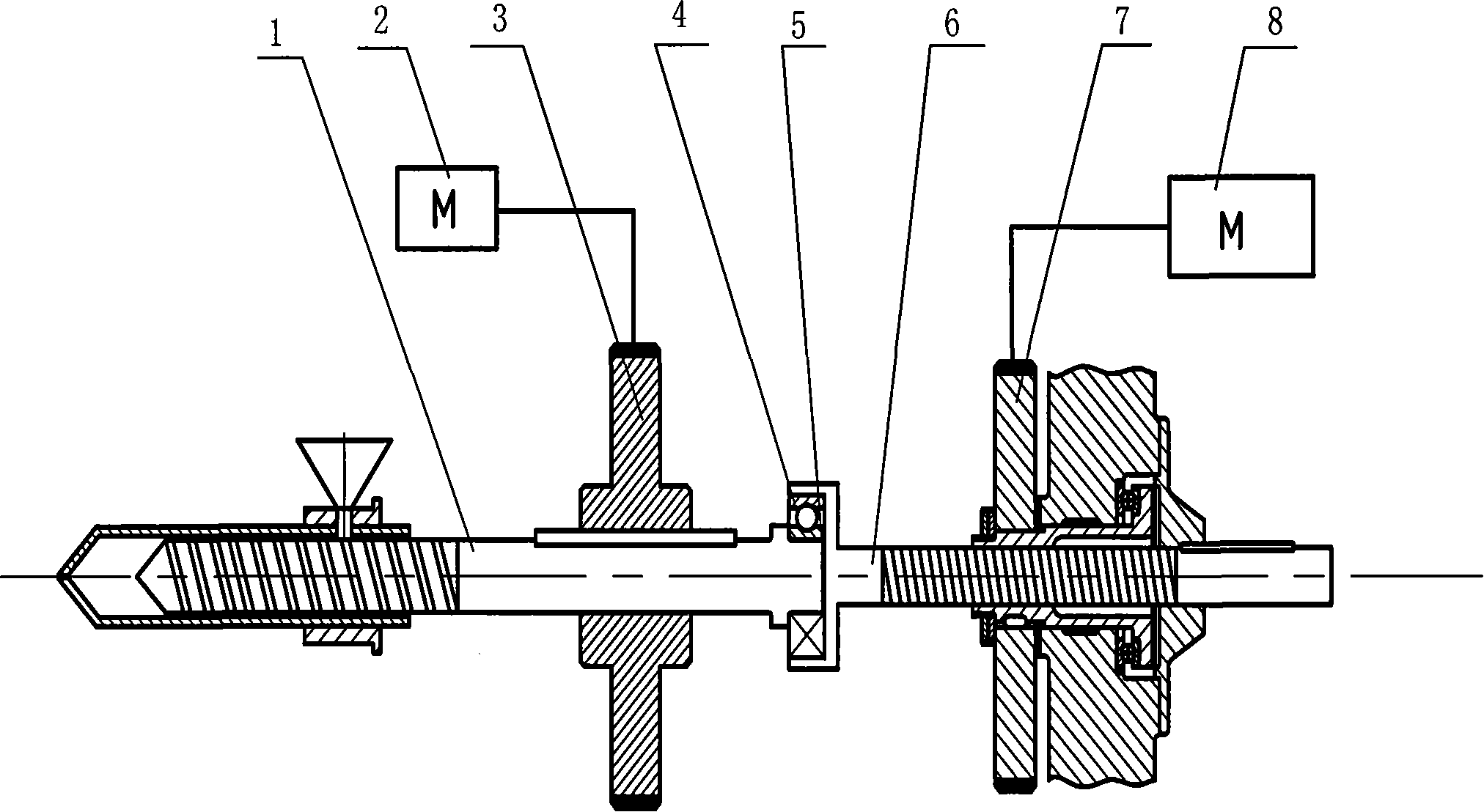

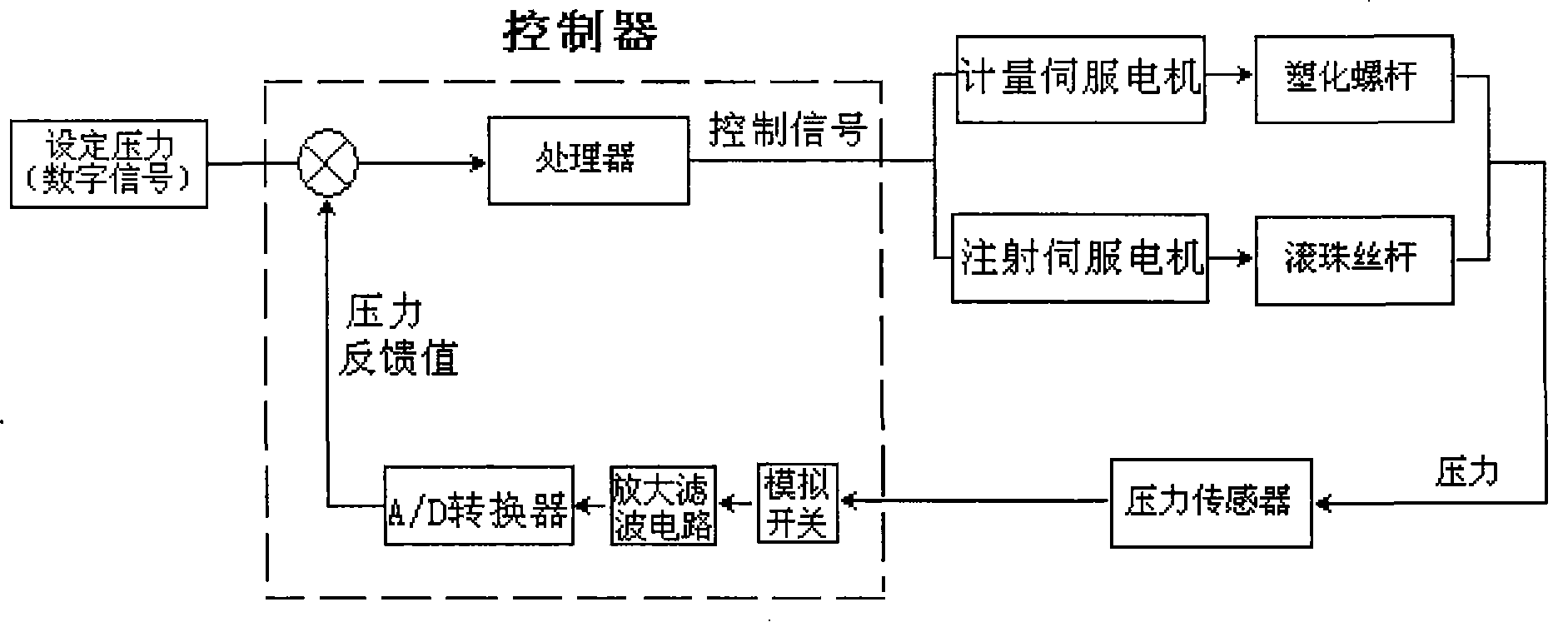

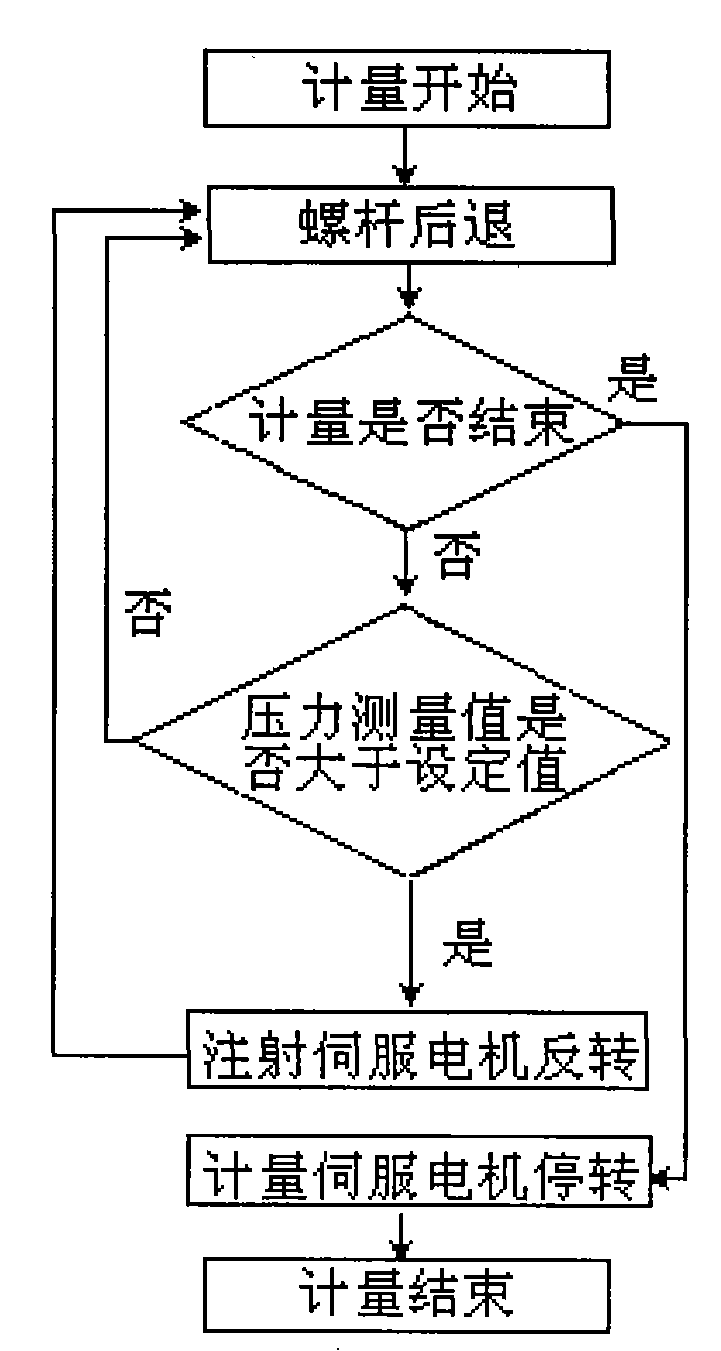

[0017] Such as figure 1 As shown, the electric plasticizing driving device with direct back pressure feedback control includes an injection servo motor, a metering servo motor, an electric plasticizing transmission mechanism, and a controller. The electric plasticizing transmission mechanism includes a screw 1, a metering gear 3, a bearing 4, and a pressure sensor 5. The screw rod 6, the injection gear 7, the screw rod 1 is provided with the metering gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com