System for treating high concentrated organic wastewater by three-phase fluidized algae photobioreactor

A photobioreactor, organic wastewater technology, applied in biological water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. control, it is difficult to meet large-scale processing requirements, etc., to achieve the effects of structure and performance improvement, continuous operation, and optimal control of the entire process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

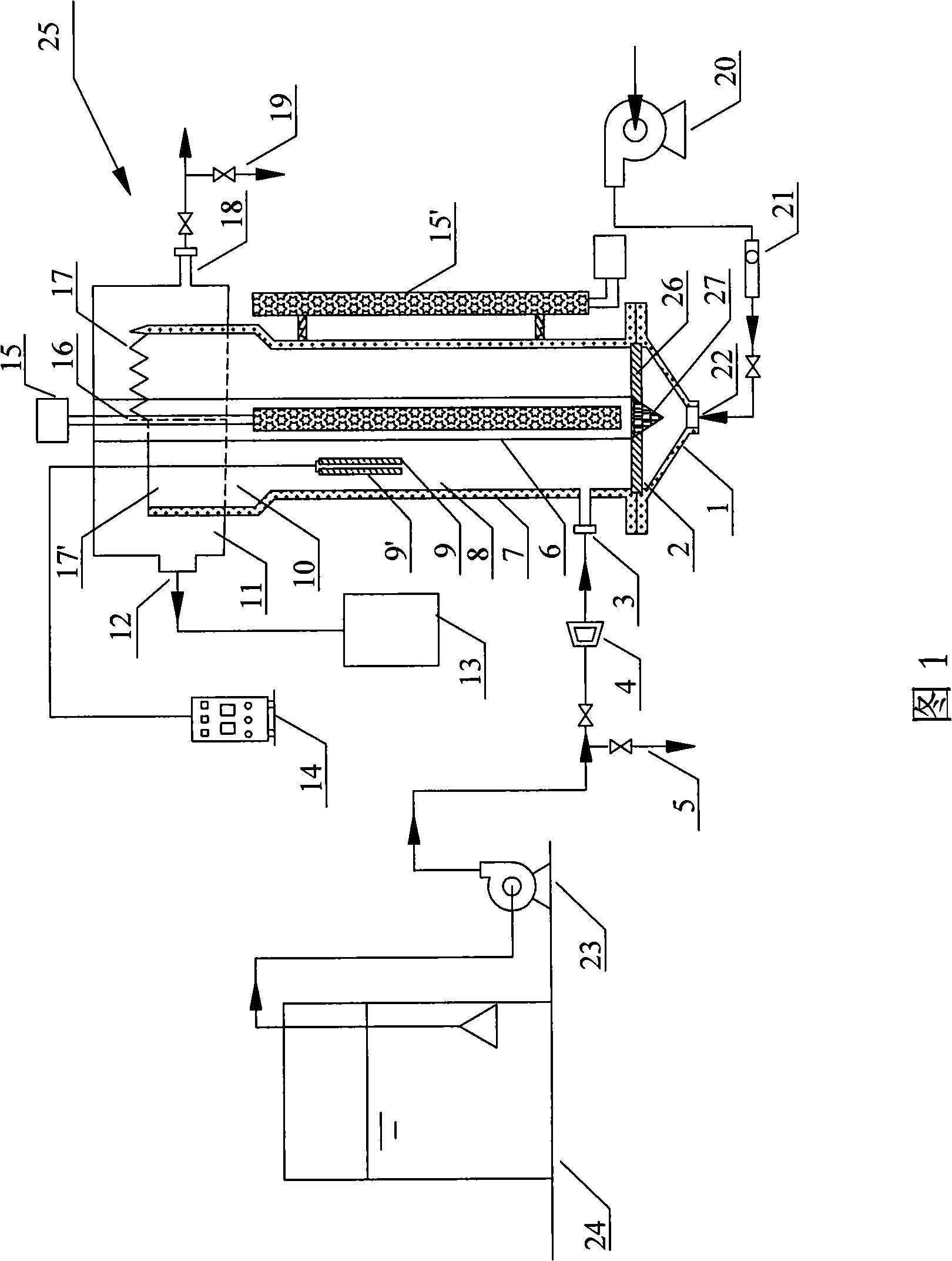

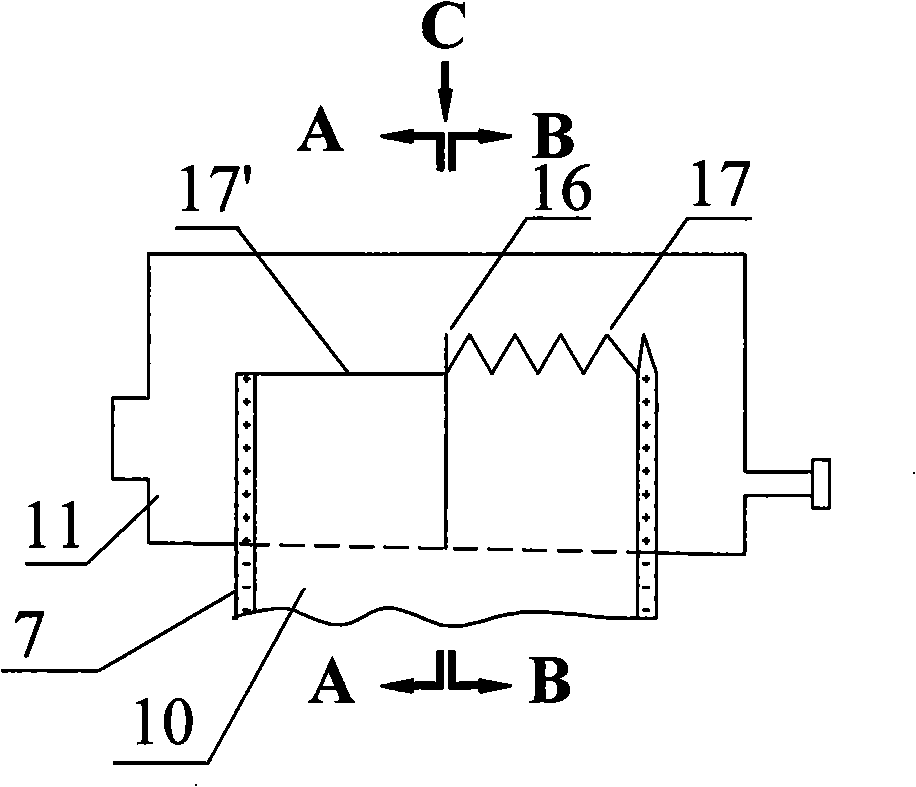

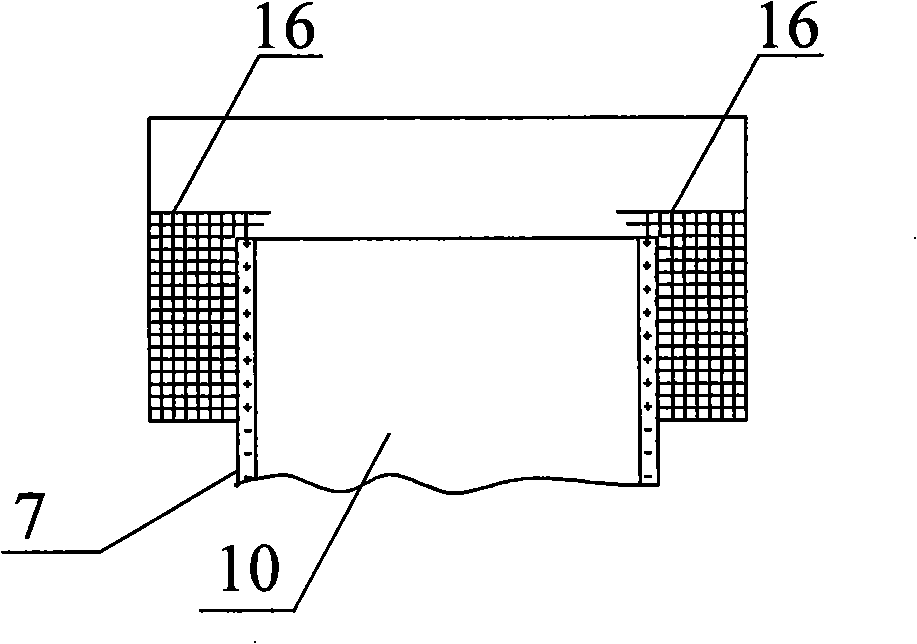

[0028] As shown in Figure 1 is the specific embodiment of the present invention, a kind of three-phase fluidized algae photobioreactor process high concentration organic waste water system, comprises regulating pool 24 and reactor 25, and reactor 25 comprises a double cylinder structure of the reaction cylinder, the reaction cylinder comprises an inner tube 6 and an outer tube 7, between the inner tube 6 and the outer tube 7 is a reaction zone 8, the reaction zone 8 is provided with a temperature detector 9 and a water quality detector 9 ', The temperature detector 9 and the water quality detector 9' are connected to the temperature control and water quality testing device 14 arranged outside the reaction cylinder; the inner tube 6 is provided with an inner light source 15, and the outer tube 7 is provided with an outer light source 15'; the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com