Composite oxidizing treatment process of micro-polluted source water

A composite oxidation and micro-pollution technology, applied in the fields of oxidized water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problem of high investment and operating costs, difficult operation control, and difficult routine treatment of ozonation products. Eliminate problems such as high water supply security, save investment costs, and achieve the effects of excellent effluent quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

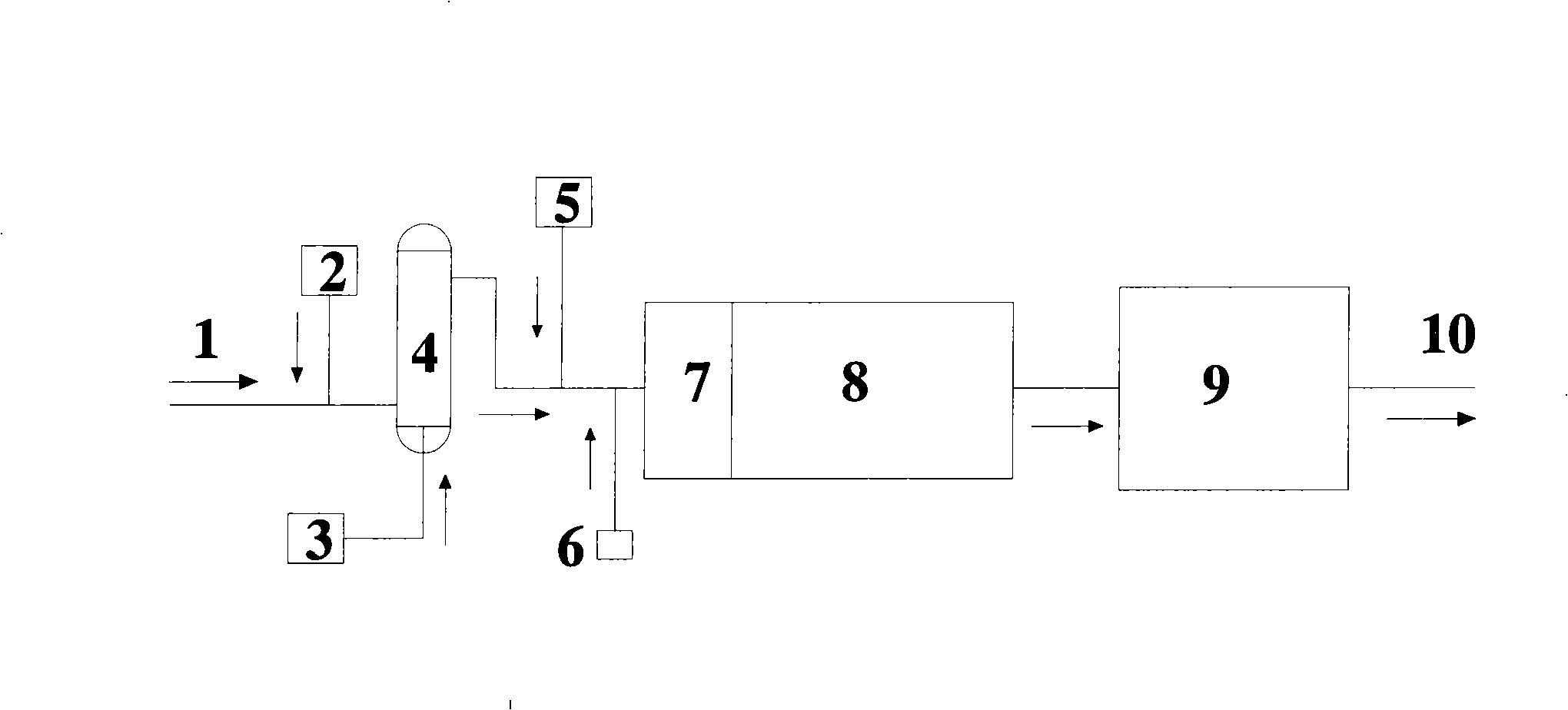

[0016] The chlorine dioxide / potassium permanganate composite pre-oxidation process is mainly based on the premise of the original treatment structure of the water plant, adding potassium permanganate dosing device, chlorine dioxide dosing device, and contact oxidation tank and other equipment. Chlorine dioxide is mixed with raw water through a water ejector and enters the contact oxidation tank, while potassium permanganate is injected into the contact oxidation tank through a pressurized pump, and the pre-oxidation process is completed after mixing. The pre-oxidized water enters the subsequent treatment structure of the water plant for treatment.

[0017] Figure 1 shows the method of this kind of chlorine dioxide / potassium permanganate composite pre-oxidation treatment of micro-polluted water. Including chlorine dioxide dosing device 2, potassium permanganate dosing device 3, contact oxidation tank 4, coagulant dosing device 5, coagulation aid dosing device 6, mechanical mixing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com