Method for separating and preparing paclitaxel

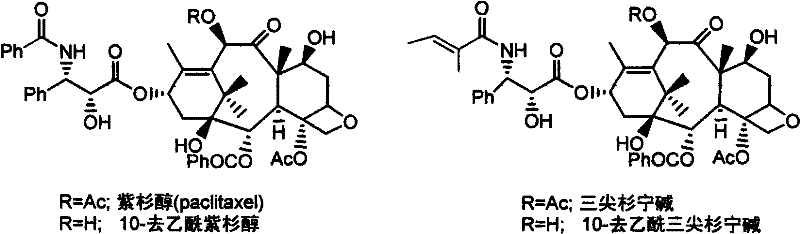

A technology for paclitaxel and taxane, which is applied in the field of preparation of paclitaxel raw materials, can solve the problems of unusable price, strong carcinogenicity and high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

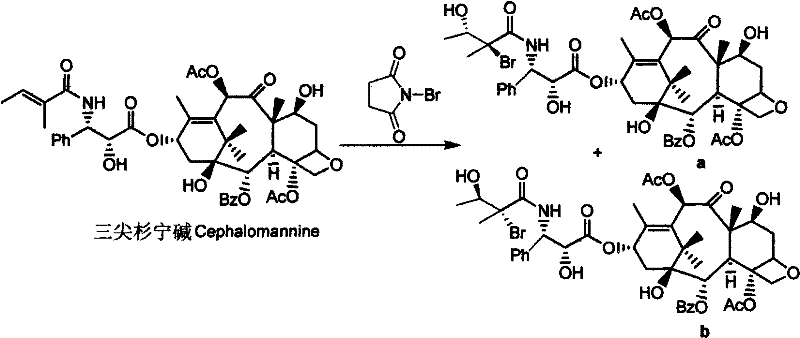

Method used

Image

Examples

Embodiment 1

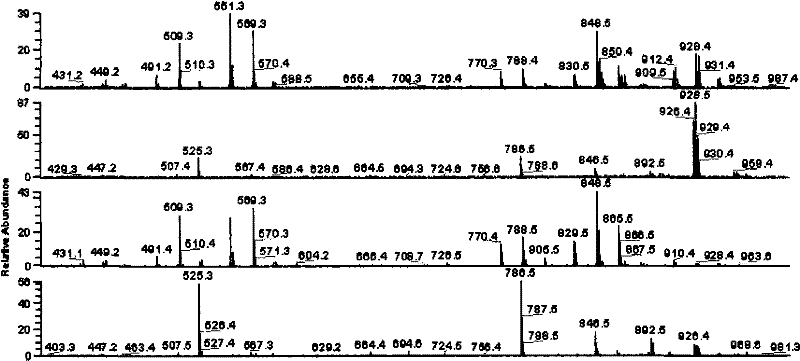

[0042] Weigh 1.0g taxane sample (containing 37% paclitaxel, 21% cephalomannine) and dissolve in 20ml methanol, add 220mg NBS and add Lewis acid, react at room temperature, HPLC detection shows cephalomannine conversion rate After reaching 95%, the feed liquid was evaporated to dryness under reduced pressure. Dissolve about 8 ml of ethyl acetate-n-hexane (1:1) and apply to the column for separation, and elute with ethyl acetate / n-hexane (1:1). The paclitaxel (purity > 90%) fraction was obtained by classifying and collecting each fraction. Adopted various Lewis acids and their consumption, reaction time, paclitaxel yield list are as follows:

[0043] Table 1. Various Lewis acids catalyze the addition of monobromomonoalkoxy groups

[0044]

Embodiment 2

[0046] Take by weighing 1.0g taxane sample (containing 37% paclitaxel, 21% cephalomannine) and dissolve in 40ml methanol: water (3:1) system, add 220mg NBS, react at 35 ℃ for 12 hours, HPLC detection shows The conversion rate of cephalomannine reaches 95%. After the addition reaction, the product was extracted three times (40ml, 10ml, 10ml) with ethyl acetate-n-hexane (1:1), and the extracts were combined and concentrated. The concentrated solution was dissolved in about 8 ml of ethyl acetate-n-hexane (1:1), and then separated by column loading, and eluted with ethyl acetate / n-hexane (5:5). The fractions of paclitaxel were collected by classification to obtain 378mg of paclitaxel with a purity of 91%. Yield 93%.

Embodiment 3

[0048] Weigh 5.00g taxane sample (37% paclitaxel, 21% cephalomannine) and dissolve it in 100ml methanol, add 10ml water and 1g NBS, react at 35°C until cephalomannine disappears, the product is washed with ethyl acetate Ester-n-hexane (1:1) extracted three times (80ml, 40ml, 20ml), combined and concentrated. The concentrate was dissolved in 40 ml of ethyl acetate-n-hexane (1:1) and separated by column. Ethyl acetate / n-hexane (5:5)-ethyl acetate / n-hexane (4:6) was used for elution. After sorting and collecting, 1.65 g of the paclitaxel fraction was obtained, with a purity of 90%. Yield 89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com