Rope-suspension bridge cable system anti-corrosive protecting method and cable system anti-corrosive protecting structure

A suspension bridge and cable technology, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problems that non-vulcanized sealants cannot provide a sealing layer, reduce anti-corrosion performance, and seal failure, so as to achieve excellent sealing anti-corrosion performance and reduce maintenance costs. The effect of good steel rust resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

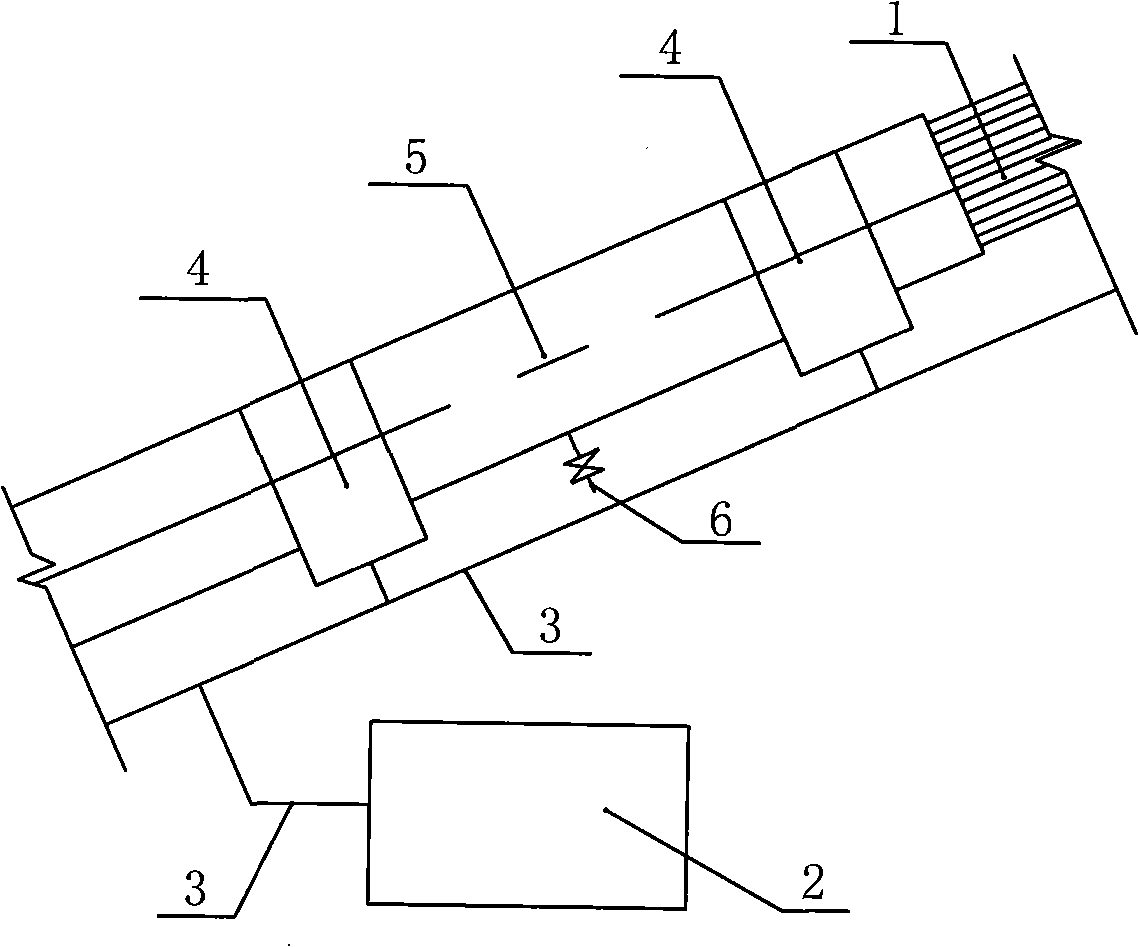

[0037] figure 1 A preferred embodiment of cleaning and dehumidification before the protective sealing of the main cable of the suspension bridge of the present invention is schematically shown. Multiple strands of high-strength galvanized steel wires form steel wire bundles with a substantially circular cross-section through multiple clamps (not shown) fixed on the main cable, and the main cable 1 is composed of steel wire bundles. According to the main cable system protection method of the present invention, the surface of the main cable 1 is routinely cleaned to remove rust and other dirt and pollutants, and then the pre-sealing layer 5 is installed and laid first. The pre-sealing layer 5 is made by coating butyl rubber elastomer with high-strength fiber cloth. Then install the dry air input air bag 4, connect the air input pipeline 3, and connect the air drying device (dehumidifier) 2. The treated clean and dry air with a relative humidity of about 20% is input into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com