Highly wear-resisting alloy steel rubber outer protection shockproof energy saving pump tube

A technology of alloy steel pipe and alloy steel, which is applied in the field of high-wear-resistant alloy steel rubber outer protection shockproof and energy-saving pump pipes. Effects of twisting, reducing noise pollution, and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

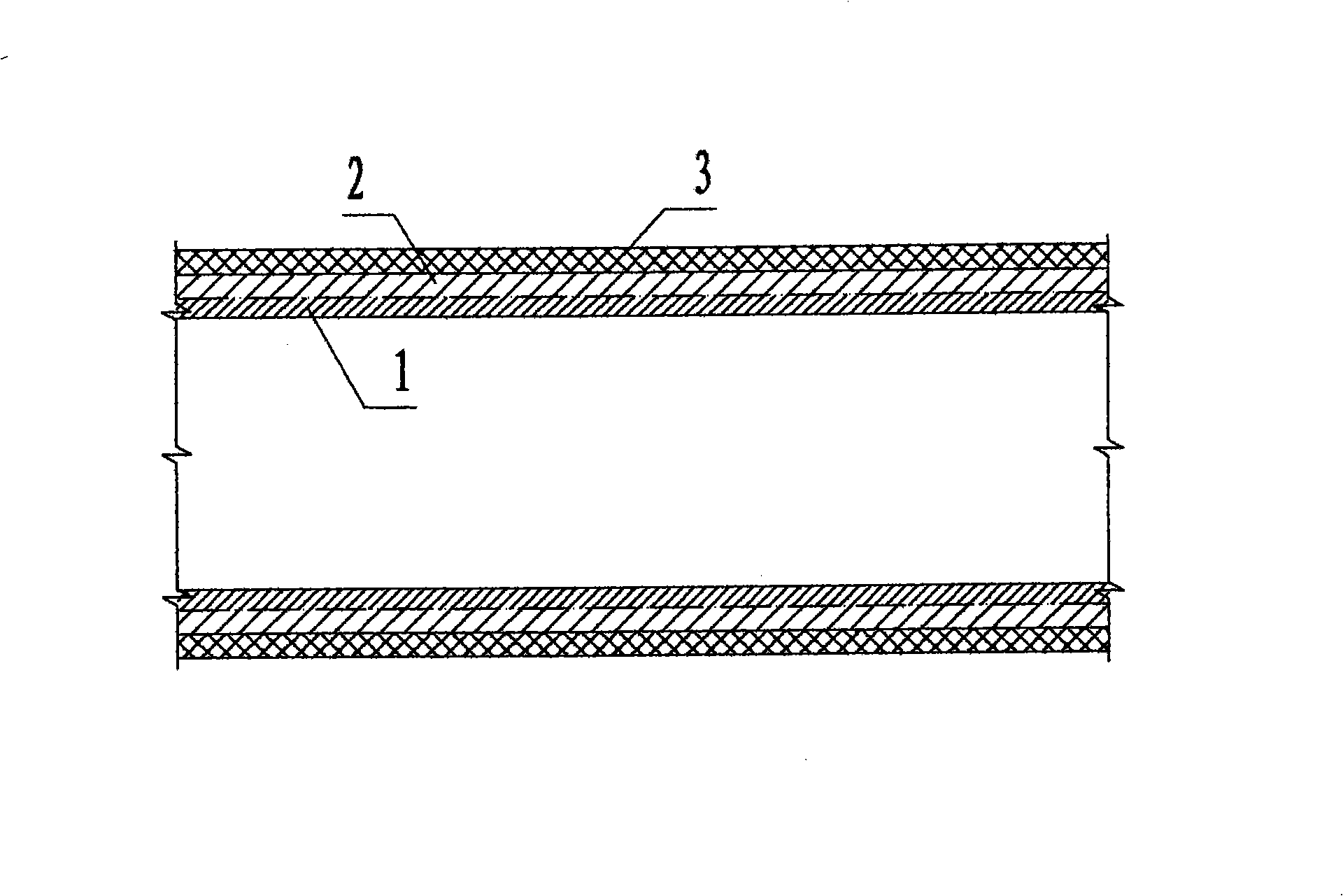

[0015] Referring to Fig. 1, the high wear-resistant alloy steel rubber outer protection shockproof energy-saving pump pipe of the present invention comprises alloy steel pipe 1, rubber outer protection 2, wherein: described alloy steel pipe 1 is 45# manganese steel seamless steel pipe, and its pipe wall passes through Heat treatment forms two layers with different hardness. The inner wall layer 11 forms a high-hardness wear-resistant layer with a thickness of several millimeters and a Rockwell hardness of 58-65 degrees through high-frequency quenching and quenching and tempering processes. The outer wall layer 12 maintains the original Rockwell hardness of the material. A high-tough, flex-resistant layer with a hardness of 22 degrees; the rubber outer sheath 2 is a damping rubber layer with a thickness of several millimeters that is densely attached to the outer wall of the alloy steel pipe through the process of encapsulation and vulcanization.

[0016] Realized process equipm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com