Nonaqueous cyanogen-free silver-plating solution

A cyanide-free silver plating and electroplating solution technology, which is applied in the field of electrochemical silver plating, can solve the problems of high cost of plating solution, inconvenient management and operation, and increased cost, and achieve good stability of plating solution, good bonding force, and fine plating bright effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

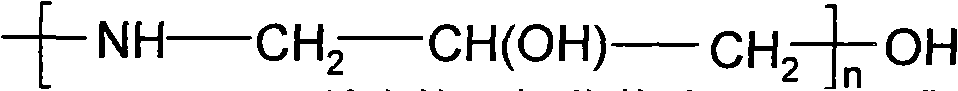

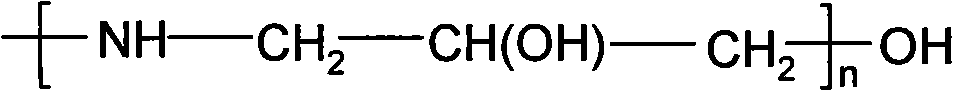

Method used

Image

Examples

Embodiment 1

[0017] According to the non-aqueous cyanide-free silver-plating solution preparation method of the present invention, the following compounds are formulated into cyanide-free silver-plating solution AgCl22g / L

[0018] TU 70g / L

[0019] DMF as a solvent (quantitatively according to actual requirements)

[0020] Cysteine 0.5g / L

[0021] pH 7

[0022] Temperature 0℃~80℃

[0023] According to the electroplating step in the specific embodiment, the electroplating operation is performed using the cyanide-free silver plating electroplating solution.

Embodiment 2

[0025] According to the preparation method of non-aqueous cyanide-free silver-plating solution of the present invention, the following compounds are prepared into cyanide-free silver-plating solution

[0026] AgNO 3 22g / L

[0027] KSCN 130g / L

[0028] DMF as a solvent (quantitatively according to actual requirements)

[0029] pH 7

[0030] Temperature 0℃~80℃

[0031] According to the electroplating step in the specific embodiment, the electroplating operation is performed using the cyanide-free silver plating electroplating solution.

Embodiment 3

[0033] According to the preparation method of non-aqueous cyanide-free silver-plating solution of the present invention, the following compounds are prepared into cyanide-free silver-plating solution

[0034] AgNO 3 17g / L

[0035] KSCN 100g / L

[0036] Dimethyl sulfoxide is used as solvent (quantitatively according to actual requirements)

[0037] pH 7

[0038] Temperature 0℃~80℃

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com