Fault handling process for temperature-controlling thermal couple of polysilicon ingot furnace

A troubleshooting method and polysilicon ingot furnace technology, applied in polycrystalline material growth, chemical instruments and methods, single crystal growth, etc., can solve problems such as temperature drop, affect silicon ingot production, and difficulty in rapid replacement, and achieve easy implementation , Troubleshooting method and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

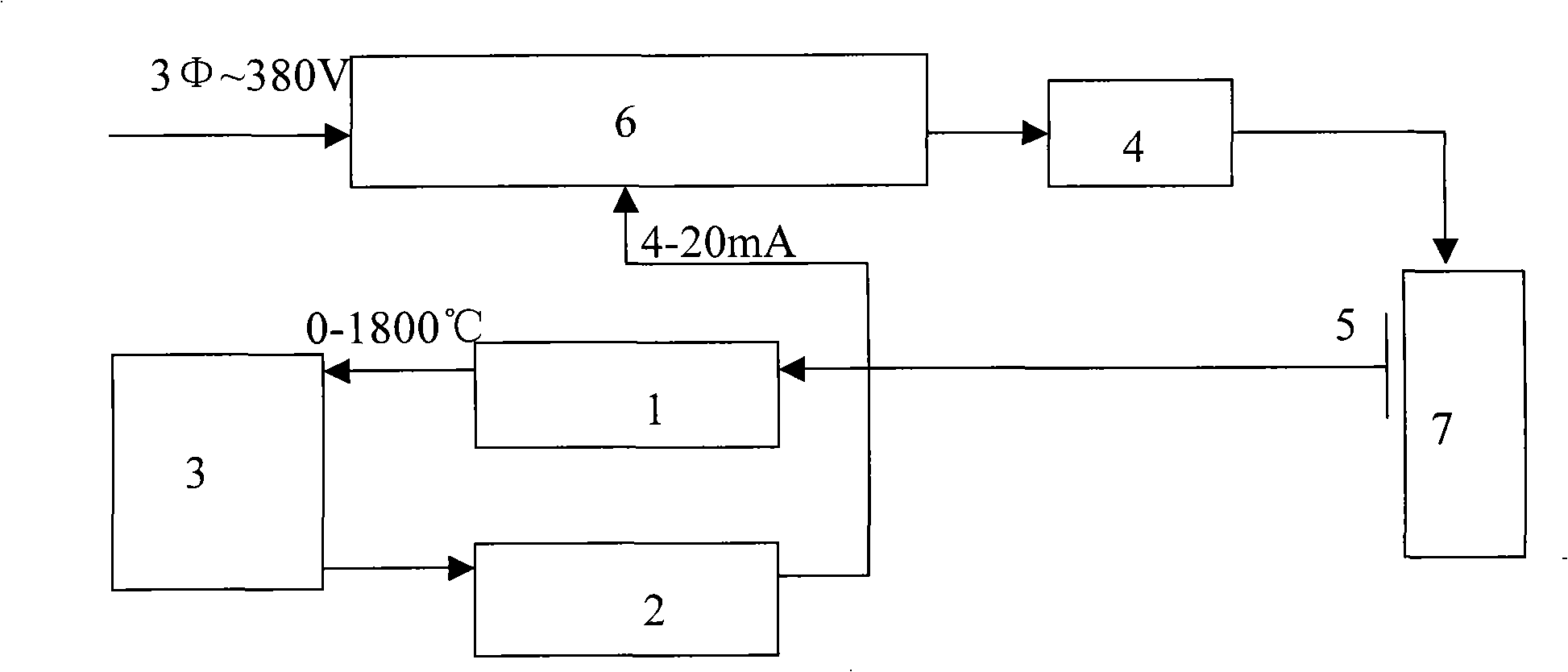

[0027] When the temperature control thermocouple 5 is working normally, the furnace temperature is detected by the temperature control thermocouple 5, which is connected to the thermocouple input module 1, and then the thermocouple input module 1 converts the analog signal into a digital signal and sends it to the controller 3. Comparing the temperature setting value with the temperature controller 3, the heating power setting value (0.0-100.0%) of the temperature closed-loop control is calculated, and the standard control signal 4.020.0mA is output by the D / A module 2, and sent to the AC three-phase intelligent controllable The control end of the silicon power controller 6 makes the heating power change linearly within the range of 0-165kW. Its AC three-phase intelligent thyristor power controller 6 has a power output of 380V / 250A, controls the main transformer 4, converts it into a low-voltage and high-current 25V / 3800A power output through the main transformer 4, and is dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com