Cultivation in vitro method for artificial cartilage or bone cartilage with different curve and bioreactor thereof

A bioreactor and in vitro culture technology, applied in the field of bioreactors, can solve problems that do not involve rolling loading, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

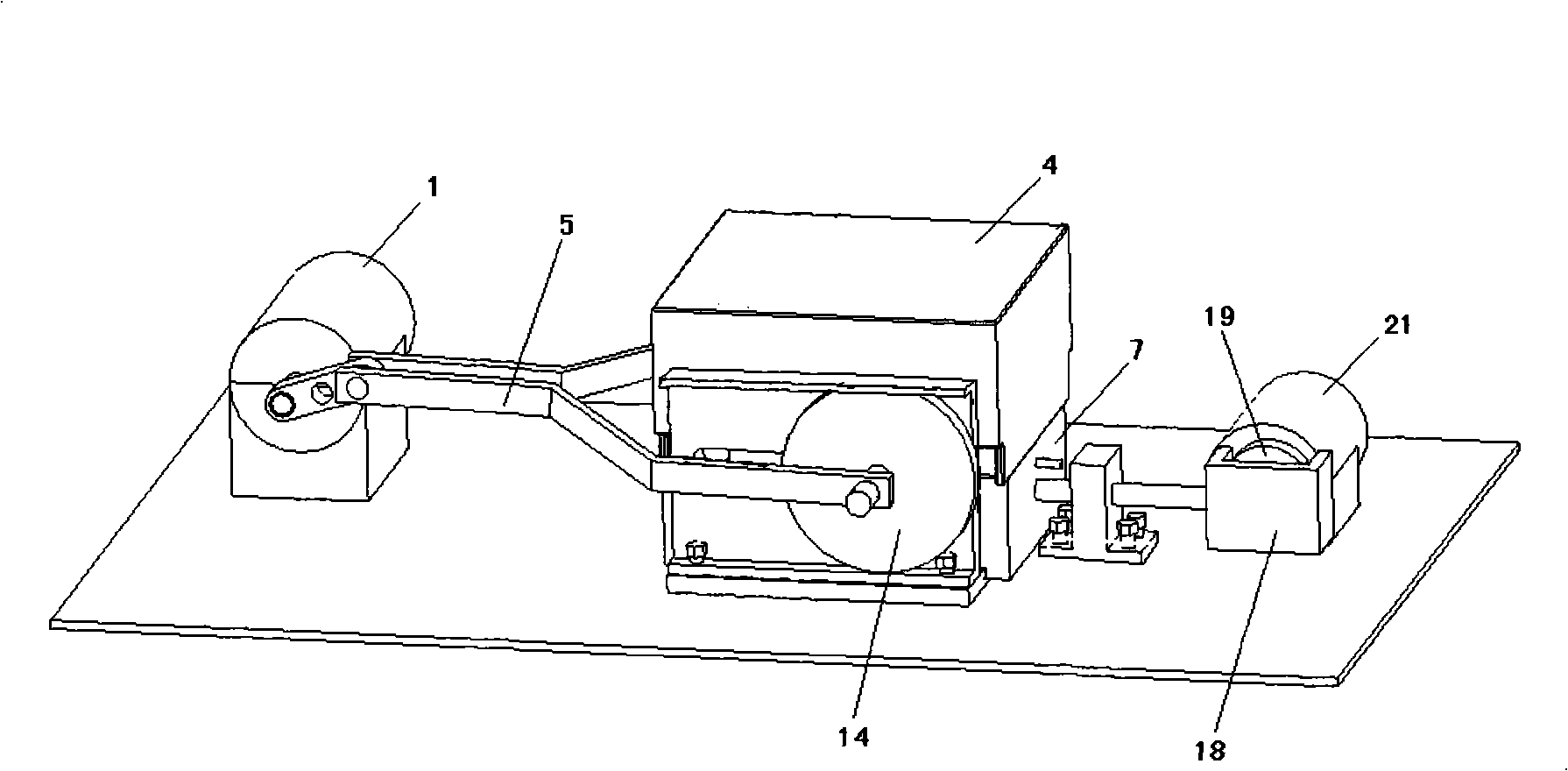

Image

Examples

example

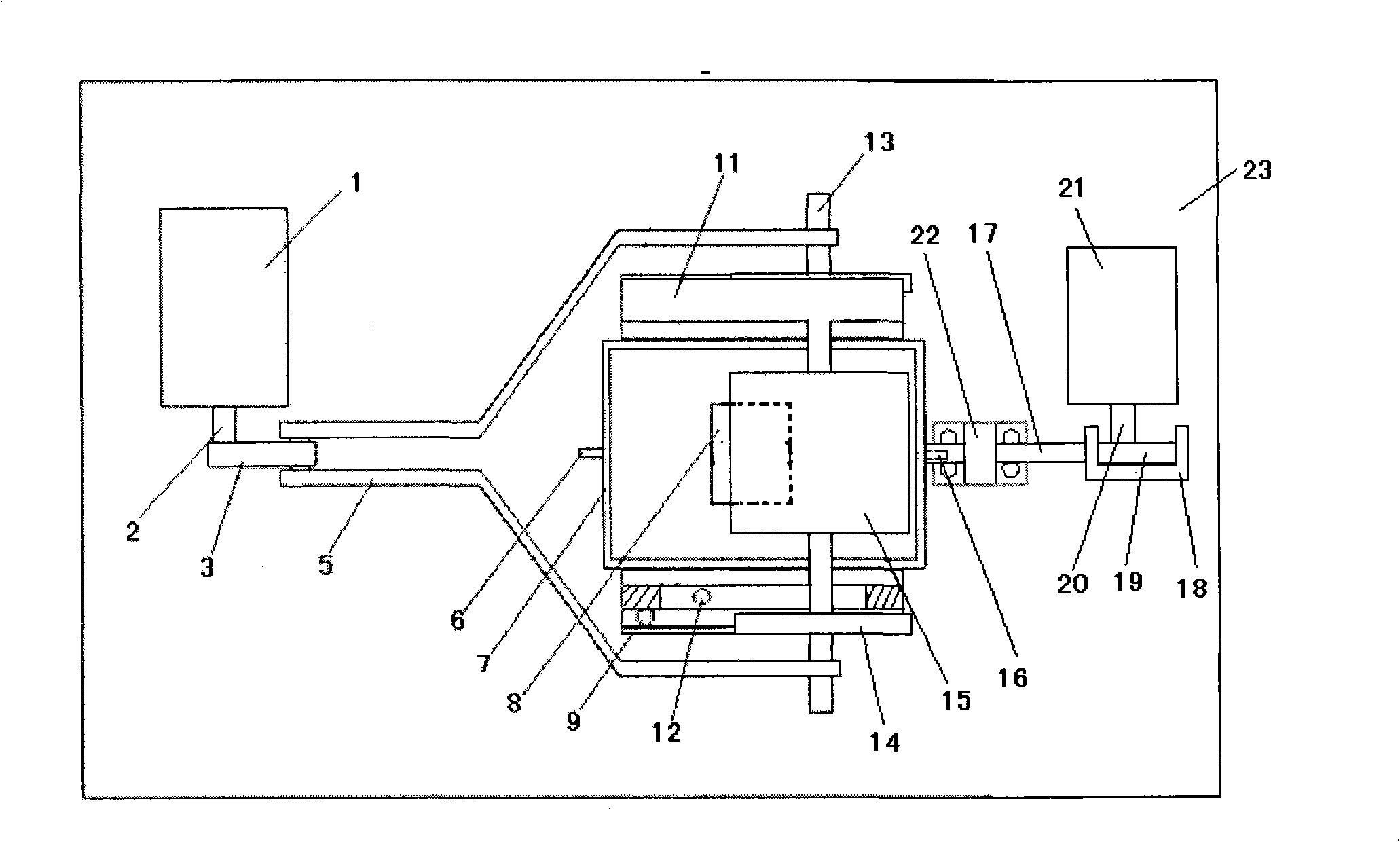

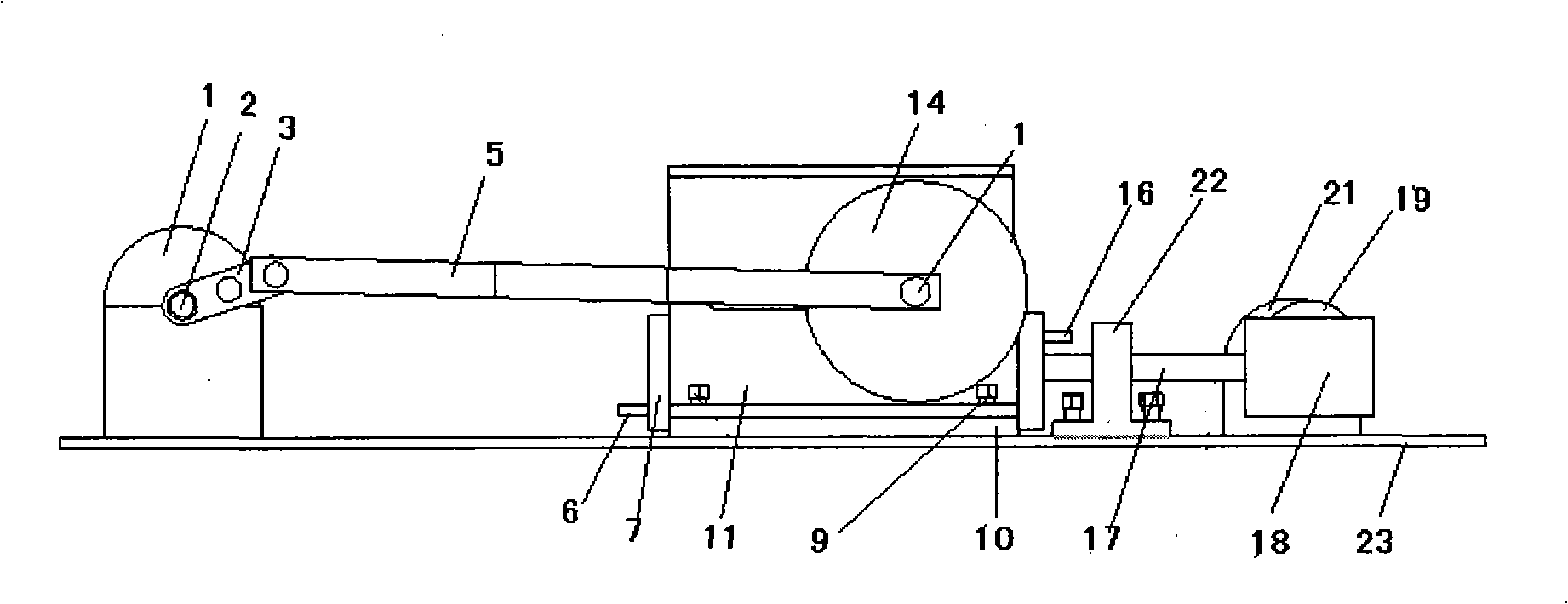

[0031] Culture method for cartilage defect

[0032] A piece of cartilage was biopsied from the non-weight-bearing area of the patient, fully rinsed with D-Hanks solution, and then initially chopped into 1-2 mm3, then transferred into a penicillin vial, digested with trypsin and collagenase, centrifuged to obtain chondrocytes, transferred into a culture bottle and added The culture medium is cultivated, and the cells are used after expansion.

[0033] The expanded chondrocytes were harvested by digestion. Cells were resuspended in fibrinogen solution to 2×10 6 / ml, mix through a Y-shaped co-push needle, pour into the mold, and stand at 37°C for 10 minutes to fully solidify to form a rectangular plate-shaped composite. Then move it to the culture room, fix it to the bottom plate of the culture room, and add culture medium to cultivate.

[0034] The reactor is placed in an incubator with O 2 , CO 2 , The temperature is automatically controlled, and the peristaltic pump dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com