Vibration damping and energy-absorbing device of vehicle auxiliary frame and method thereof

A technology of energy-absorbing device and sub-frame, which is applied in the direction of measuring device, vehicle suspension/shock-absorbing mechanism test, suspension, etc., to achieve good vibration-damping effect, simple structure, and reduced transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

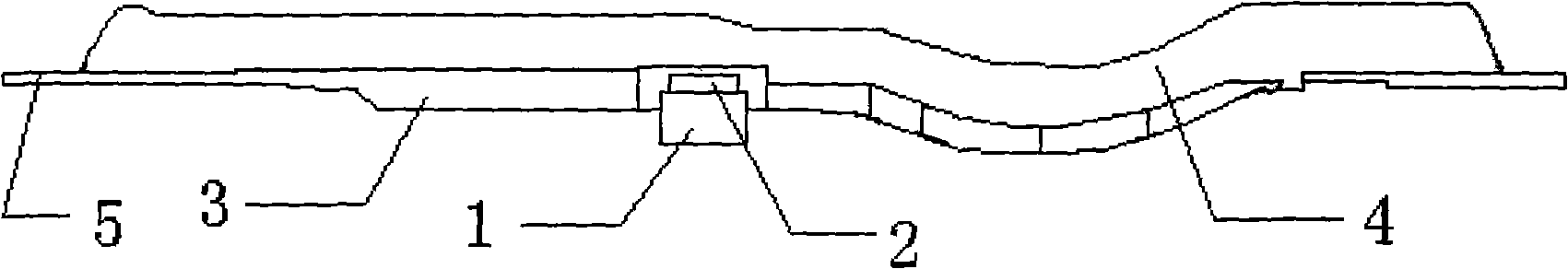

[0017] Example 1 as figure 1 As shown, a vibration-damping and energy-absorbing device on the sub-frame of an automobile includes a sub-frame formed by welding the sub-frame lower body 3 and the sub-frame upper body 4, and the sub-frame is connected to the engine and the vehicle body. The method is: an elastic body 2 with elastic damping is arranged at the weakest part of the rigidity of the lower body of the sub-frame (corresponding to the position of maximum displacement) and connected with the mass block 1 . Elastic body 2 is rubber, also can be spring.

[0018] How to design the vibration damping and energy absorption of the sub-frame of the automobile, the steps are as follows:

[0019] 1. Carry out finite element analysis and simulation on the sub-frame to obtain the quality, first-order bending mode and corresponding maximum displacement of the sub-frame;

[0020] 2. Set a mass block with an elastic damping system at the position corresponding to the maximum displacem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com