Biological oxidation filter material, filter material preparation and application of the same in odor treatment

A technology of biological oxidation and filter material, applied in chemical instruments and methods, separation methods, air quality improvement, etc. Guaranteed mass reproduction, long service life and quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Implementation example 1, the preparation of bio-oxidation filter material: 1, 70% of cow dung, 5% of chicken manure, 6% of straw, 1% of cornmeal, 1% of rice straw and 12% of soil are mixed and crushed to below 5 cm; 2, crushed The final raw materials are mixed evenly, and the humidity is adjusted at about 50%; 3. Primary fermentation: The fermentation cycle is about 40 days. At this stage, when the temperature exceeds 70°C, turn over every 3 days or so to increase the oxygen demand. According to the fermentation situation, the water content is controlled at more than 50% by spraying water; 4. Secondary fermentation: the fermentation period is about 30 days, and the reaction at this stage is relatively stable, and the oxygen consumption is small. For fermentation, use water spray to control the water content above 50%; 5. Finished product treatment: After the fermentation is over, sieve the stacked materials below 0.5mm, and take the undersieve; 6. Sludge mixing: mix wit...

Embodiment 1

[0014] The application of the biological oxidation filter material of embodiment 1 gained in odor control:

[0015] The application of biological oxidation filter material in odor control is to fix the biological oxidation filter material through a spherical bracket and put it into the biological oxidation trickling filter device. When the odor passes through the biological oxidation filter ball, the components in the odor will be biologically filtered. The microorganisms in the feed are captured and oxidized and decomposed for utilization.

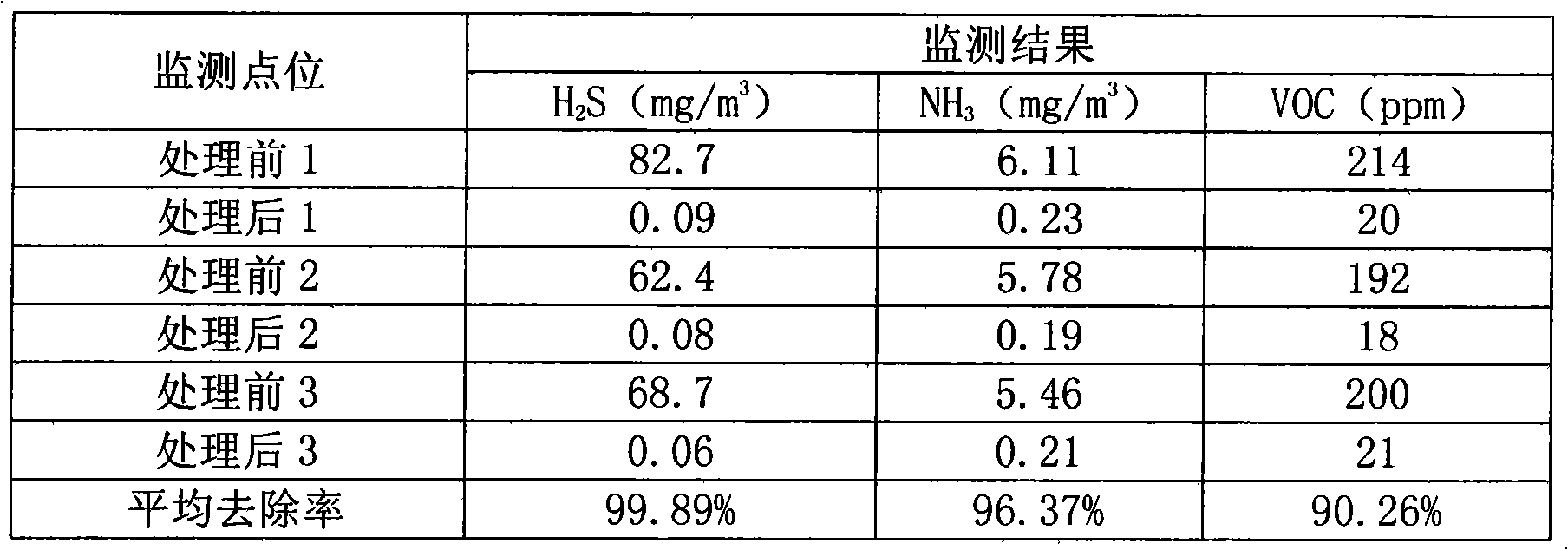

[0016] Taking the example of waste gas treatment in the sludge dehydration workshop of a sewage treatment plant to illustrate, the item monitored this time is the main component of the odor, H 2 S and NH 3 And the detection of volatile organic compounds VOC before and after the filter material is monitored at the same time. The test results five days after the test are shown in Table 2:

[0017] Table 2

[0018]

[0019] It can be ...

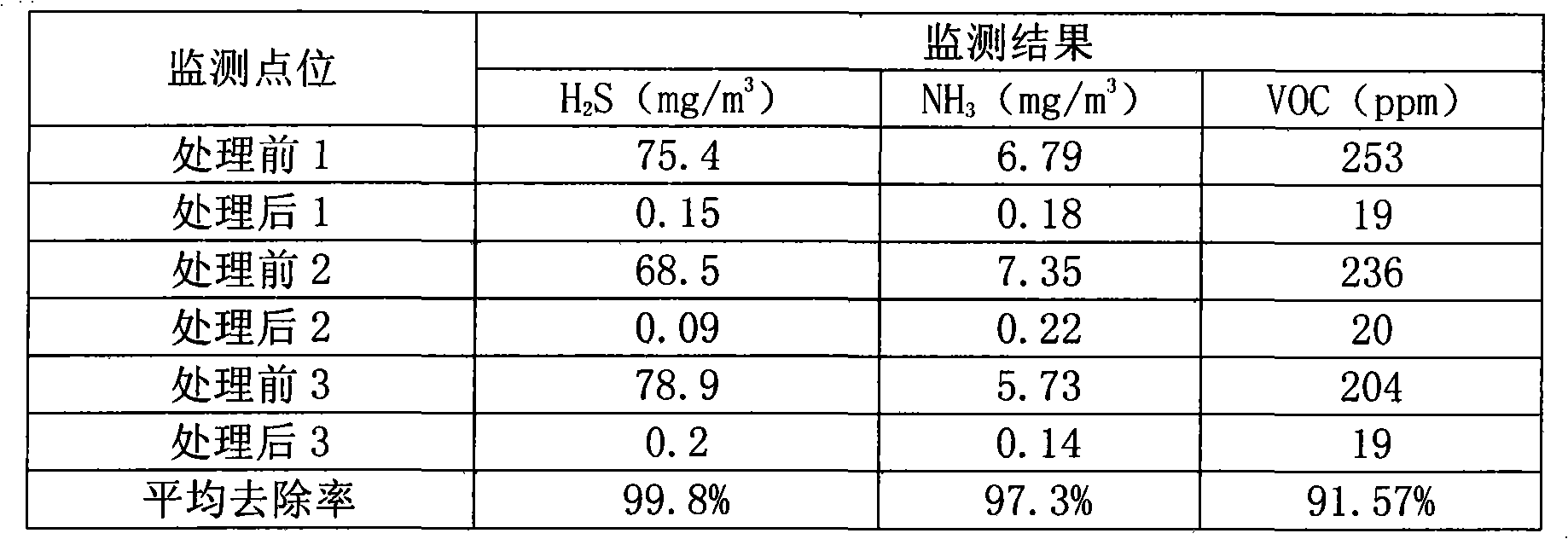

Embodiment 3

[0024] Implementation example 3, the preparation of biological oxidation filter material: 1, 50% of cow dung, 10% of chicken manure, 10% of straw, 3% of cornmeal, 4% of straw and 15% of soil are mixed and crushed to below 5 cm; 2, crushed The final raw materials are mixed evenly, and the humidity is adjusted at about 50%; 3. Primary fermentation: The fermentation cycle is about 40 days. At this stage, when the temperature exceeds 70°C, turn over every 3 days or so to increase the oxygen demand. According to the fermentation situation, the water content is controlled at more than 50% by spraying water; 4. Secondary fermentation: the fermentation period is about 30 days, and the reaction at this stage is relatively stable, and the oxygen consumption is small. For fermentation, use water spray to control the water content above 50%; 5. Finished product treatment: After the fermentation is over, sieve the stacked materials below 0.5mm, and take the undersieve; 6. Sludge mixing: mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com