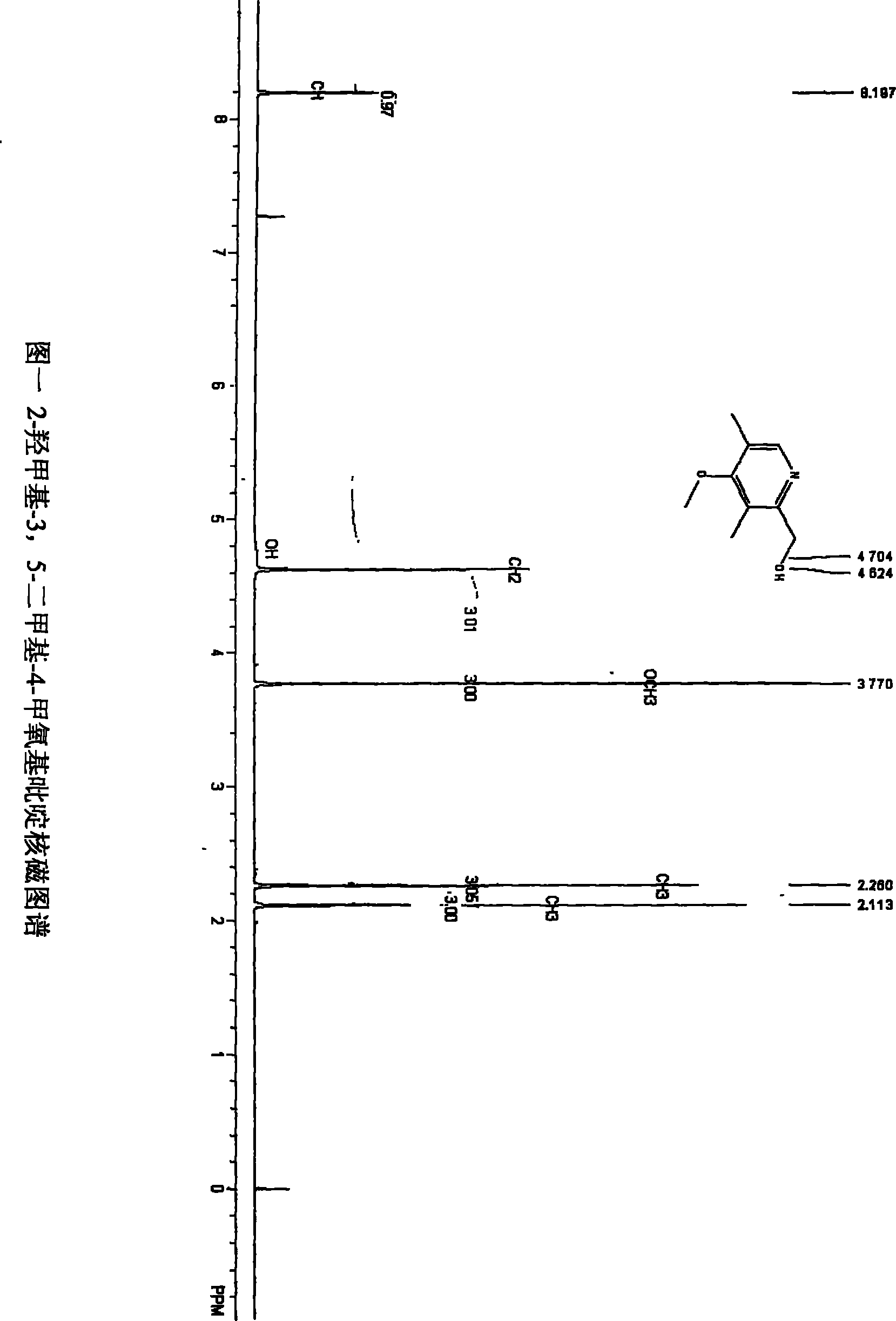

Process for the separation of 2-hydroxymethyl-3, 5-dimethyl-4-methoxy pyridine

A methoxypyridine and separation method technology, which is applied in the field of separation and purification of 2-hydroxymethyl-3, can solve problems such as difficult refining, affecting yield, increasing solubility, etc., to reduce environmental pollution, reduce production costs, and increase yield rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The method for separating and purifying 2-hydroxymethyl-3,5-dimethyl-4-methoxypyridine by molecular distillation, the proportion of high boiling point high polymer is about 10%, including the following steps:

[0027] (1) Molecular distillation to remove high-boiling-point polymer impurities: In the molecular distillation system, control the oil bath heating temperature to 150-250°C, vacuum degree ≤ 20mmHg, slowly add 500ml of 2-hydroxymethyl- 3,5-Dimethyl-4-methoxypyridine mother liquor was added at a speed of 10ml / min, and it took about 50 minutes to complete the addition, and the gas phase condensate was collected, about 450ml, and the distillation was stopped.

[0028] (2) Rectification to remove pyridine derivative impurities: In the rectification system of a 500ml three-necked flask and a φ20mm×800mm packed column, add 450ml of the easy-boiling liquid obtained by molecular distillation, separate by rectification under reduced pressure, and control the temperature o...

Embodiment 2

[0031] The method for separating and purifying 2-hydroxymethyl-3,5-dimethyl-4-methoxypyridine by scraper film distillation method, the proportion of high boiling point high polymer is about 10%, including the following steps:

[0032] (1) Scraper film distillation to remove high boiling point high polymer impurities: at 2m 2 In the scraper film distillation system, control the temperature of the oil bath at 180-220°C, the degree of vacuum ≤10mmHg, the speed of the scraper at 150 rpm, and slowly add the centrifugally separated 2-hydroxymethyl-3,5 at a rate of 200kg / h. - Dimethyl-4-methoxypyridine mother liquor 1000kg, add about 5h, collect and evaporate liquid, about 900kg, stop distillation;

[0033] (2) Rectification to remove impurities of pyridine derivatives: In the rectification system of a 1000L stainless steel tower kettle and a stainless steel screen rectification tower with a tower diameter of φ300×6000mm, add 900kg of 2-hydroxyl distilled from the scraped film distil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com