Preparation method of strontium bismuth tantalite nanometer line

A strontium bismuth tantalate nanometer and elemental technology, which is applied in chemical instruments and methods, single crystal growth, polycrystalline material growth, etc., can solve problems such as the inability to synthesize strontium bismuth tantalate nanowires, and achieve simple equipment and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

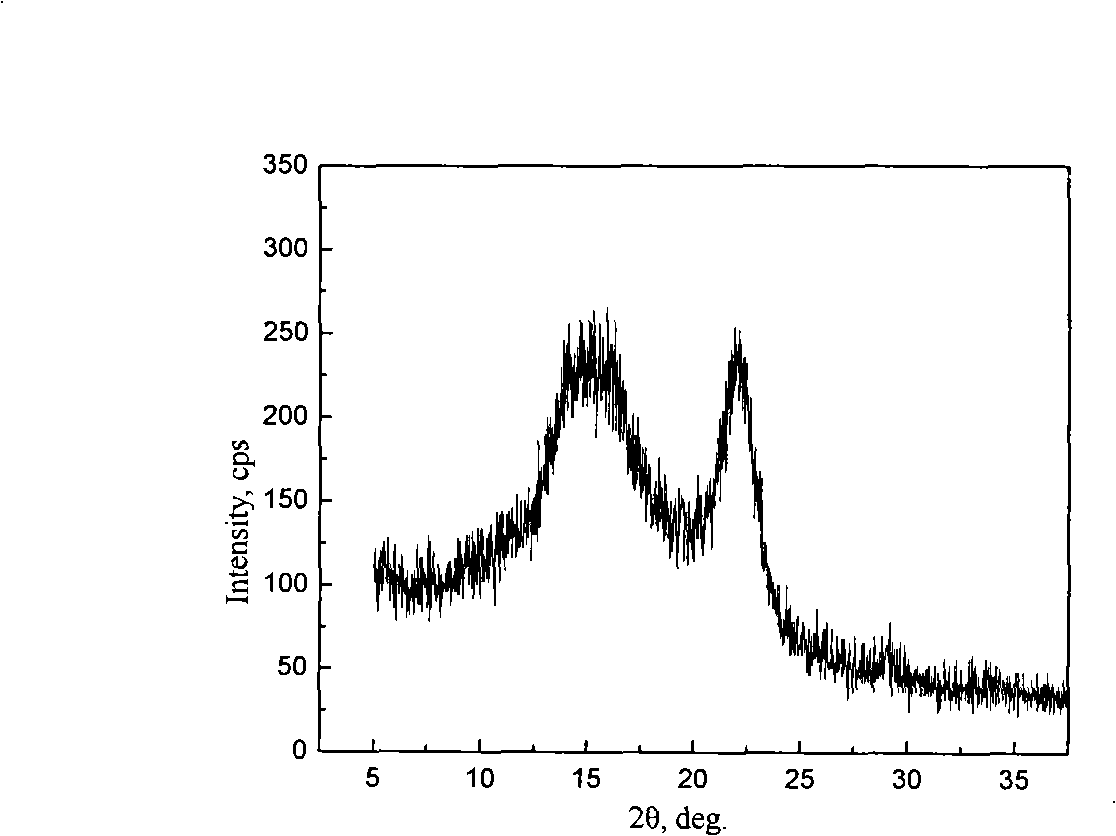

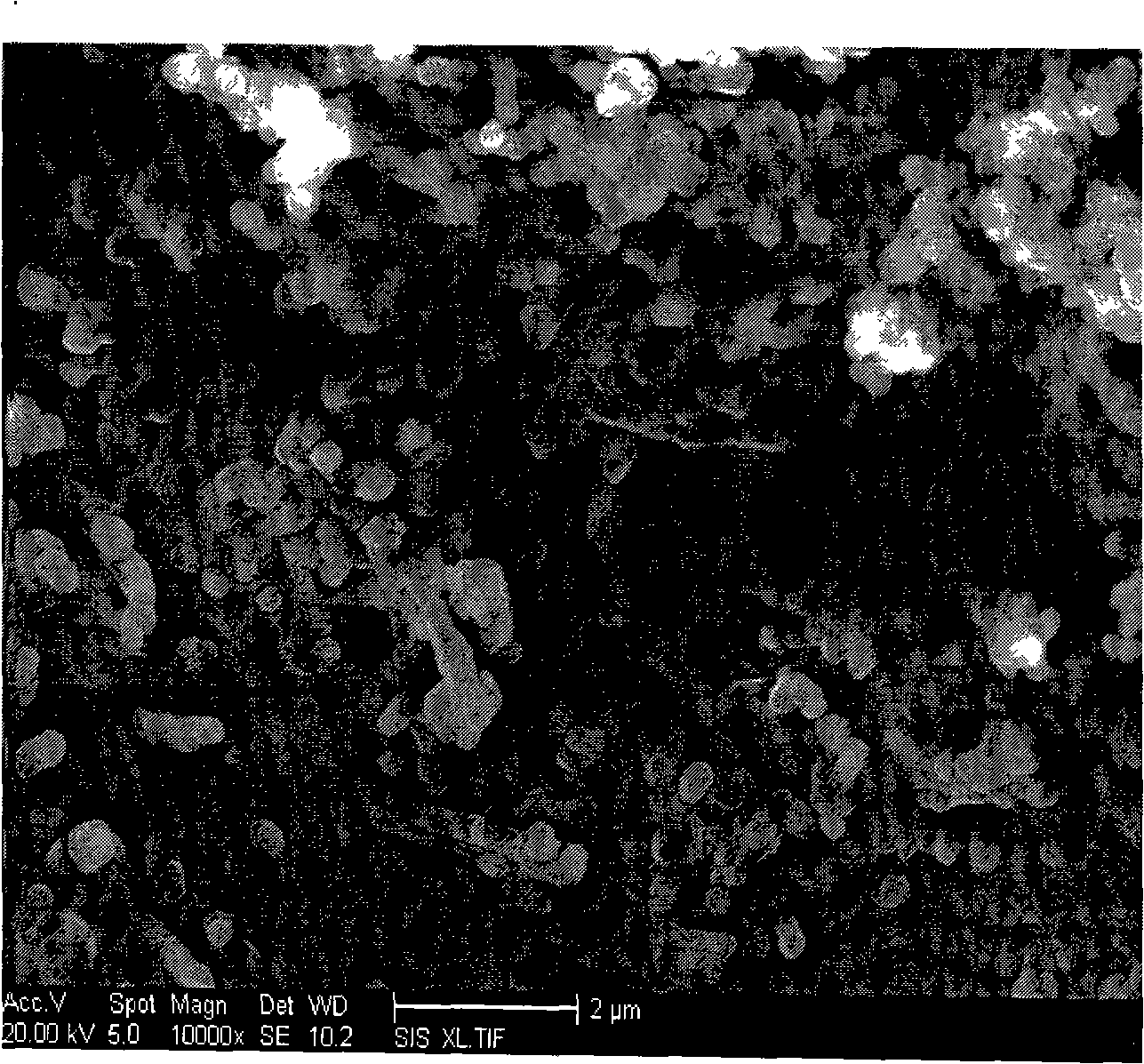

[0008] Specific embodiment 1: The preparation method of strontium bismuth tantalate nanowires in this embodiment is realized according to the following steps: 1. Weigh strontium acetate, bismuth subnitrate and tantalum ethoxide, and then stirred on a magnetic stirrer for 18-20 hours to obtain clear, transparent and stable SrBi 2 Ta 2 o 9 Precursor sol; 2. The SBT precursor sol is deposited in the AAO template hole by electrophoretic deposition, and the electrophoretic poles are placed into the SBT precursor sol at room temperature. The distance between the plates is 1cm, and the voltage between the plates is 1 ~20V, continuous treatment for 1~5min; 3. Take out the AAO template for calcination treatment, raise the temperature from room temperature to 450℃ at a rate of 3~5℃ / min, keep it for 1h, and then continue to heat up at a rate of 5~10℃ / min To 700°C, keep warm for 0.5h, and then cool to 180°C with the furnace; 4. Put the calcined product into NaOH solution with a molar co...

specific Embodiment approach 2

[0013] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the stirring time in step one is 19h. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0014] Embodiment 3: This embodiment is different from Embodiment 1 in that the voltage between the plates in step 2 is 2-15V. Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com