External heat-insulation plate for external wall and its construction method

A technology for external wall thermal insulation and construction method, applied in thermal insulation, wall, building materials and other directions, can solve the problem of inability to guarantee the firmness of the thermal insulation system and the wall, high requirements for the flatness of the base wall, and large limitations on the external finish. problems, to achieve the effect of light weight, fast construction speed, and less process overlap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

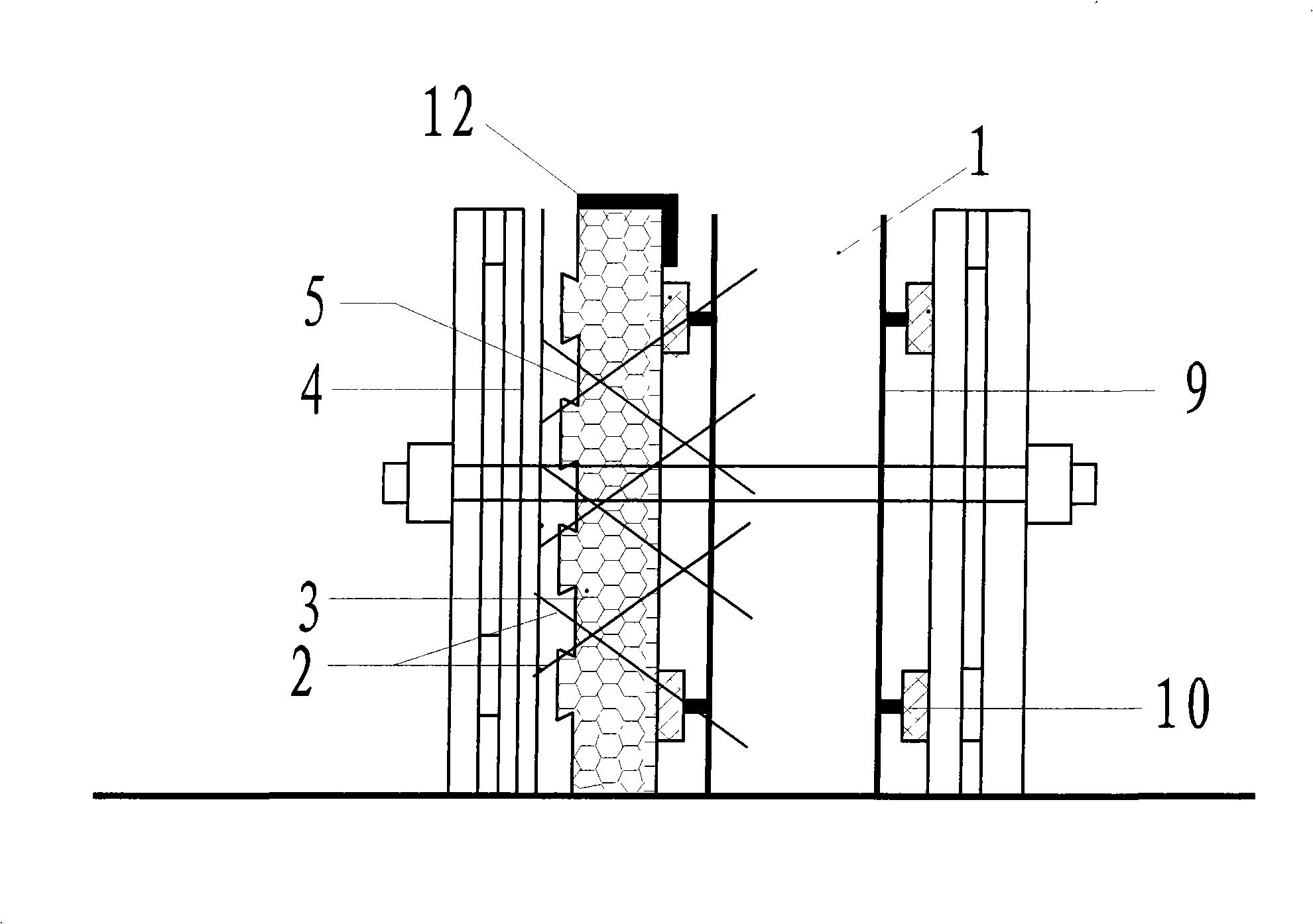

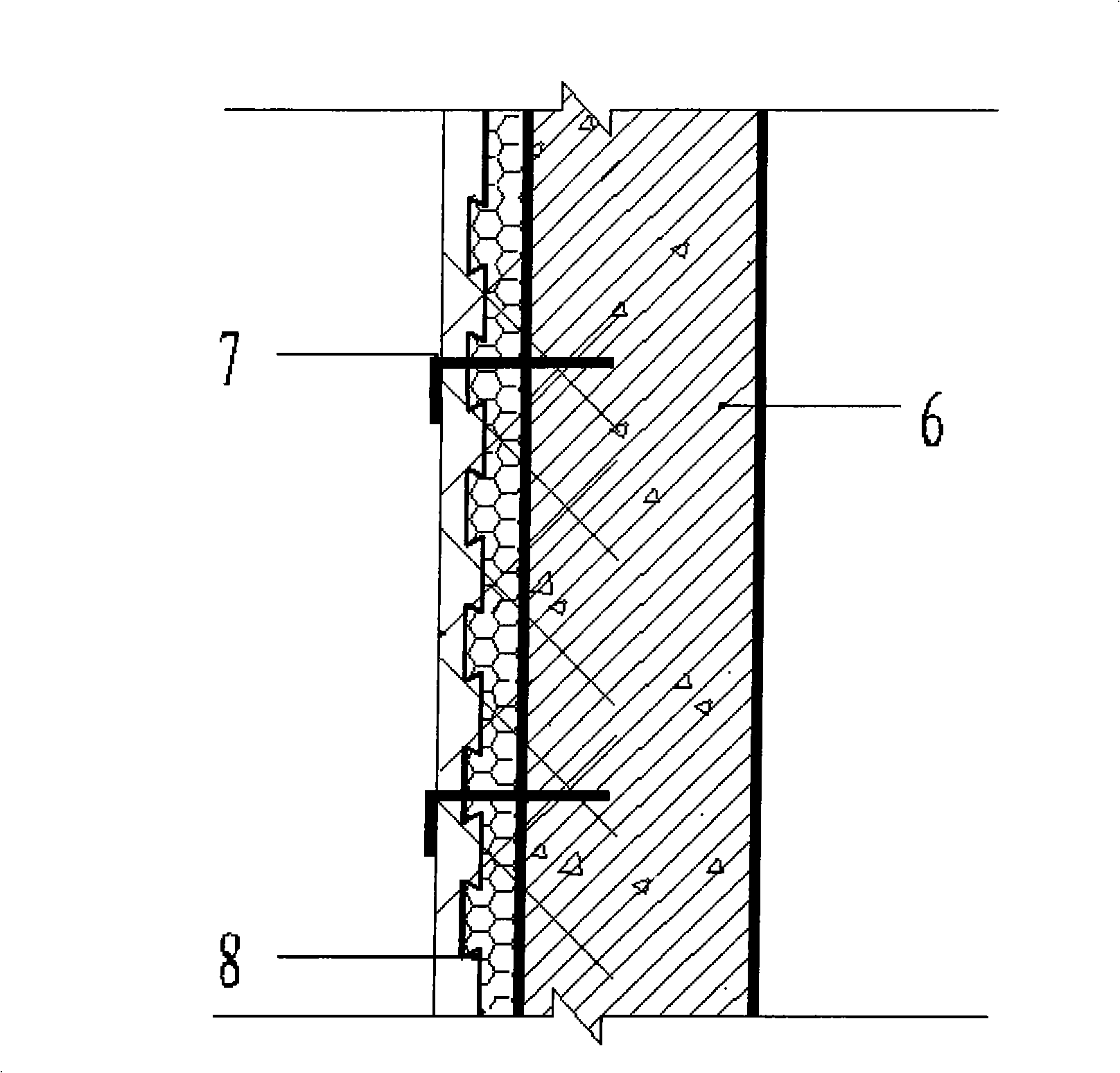

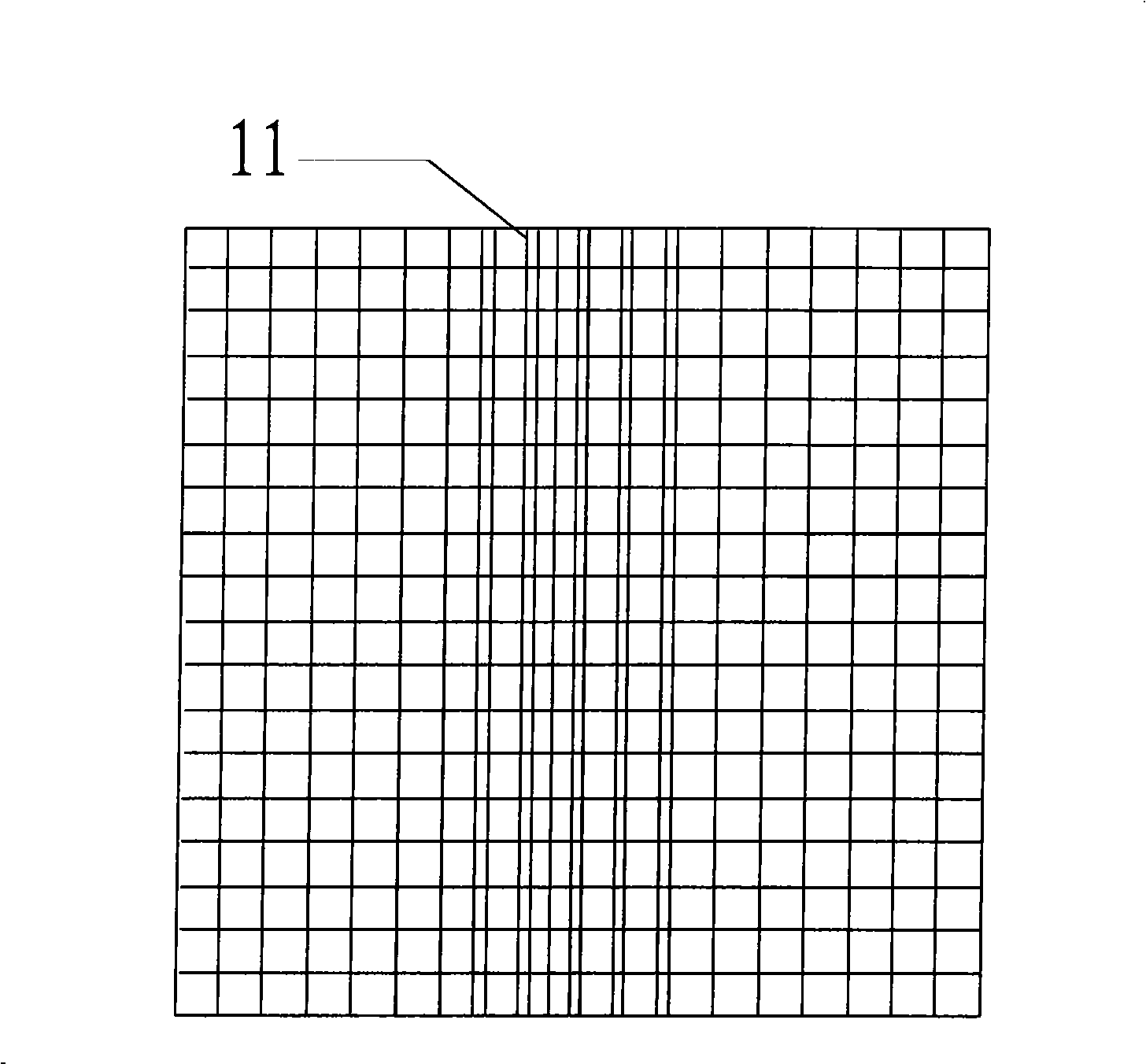

[0022] (1) First prepare the external wall insulation board, which includes preparing flame-retardant polystyrene foam polystyrene boards, and then set up multiple rows of trapezoidal ash-hanging tooth grooves at intervals on one side of the polystyrene boards (the thickness of the board is 50mm, the depth of the tooth groove is 12mm, the width of the bottom of the tooth is 40mm, and the width of the tooth top is 50mm) and a galvanized steel wire mesh is hung on the side, the grid is 5 × 5cm, and then inserted on the polystyrene board Upper two-way obliquely inserted steel wire, the angle between the obliquely inserted steel wire and the horizontal plane is 40°, and the described steel wire is fixedly connected with the described steel wire mesh and passes through the described polystyrene board; (2) the A plurality of prepared external wall insulation boards are obliquely inserted with steel wires protruding from the head and installed on the outside of the bound steel skeleto...

Embodiment 2

[0025](1) First prepare the external wall insulation board, which includes preparing flame-retardant polystyrene foam polystyrene boards, and then set up multiple rows of trapezoidal ash-hanging tooth grooves at intervals on one side of the polystyrene boards (the thickness of the board is 50mm, the depth of the tooth groove is 11mm, the width of the tooth bottom is 39mm, and the width of the tooth top is 49mm) and a galvanized steel wire mesh sheet is hung on the side, the grid is 5 × 5cm, and then inserted on the polystyrene board Upper two-way obliquely inserted steel wire, the angle between the obliquely inserted steel wire and the horizontal plane is 45°, and the described steel wire is fixedly connected with the described steel wire mesh and passes through the described polystyrene board; (2) the A plurality of prepared external wall insulation boards are obliquely inserted with steel wires protruding inwards and installed on the outside of the bound steel skeleton throug...

Embodiment 3

[0028] (1) First prepare the external wall insulation board, which includes preparing flame-retardant polystyrene foam polystyrene boards, and then set up multiple rows of trapezoidal ash-hanging tooth grooves at intervals on one side of the polystyrene boards (the thickness of the board is 50mm, the depth of the tooth groove is 10mm, the width of the bottom of the tooth is 38mm, and the width of the tooth top is 48mm) and a galvanized steel wire mesh is hung on the side, the grid is 5 × 5cm, and then inserted on the polystyrene board Upper two-way obliquely inserted steel wire, the included angle between the obliquely inserted steel wire and the horizontal plane is 60°, and the described steel wire is fixedly connected with the described steel wire mesh sheet and penetrates the described polystyrene board; (2) the A plurality of prepared external wall insulation boards are obliquely inserted with steel wires protruding inwards and installed on the outside of the bound steel sk...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com