Novel floating build floor and its construction method

A technology for floating floor and building construction, applied in the direction of floor, building, building components, etc., can solve the problems of difficult construction, low cost performance, easy to mold and other problems, achieve excellent flexibility and chemical resistance, small compression permanent deformation, Excellent resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

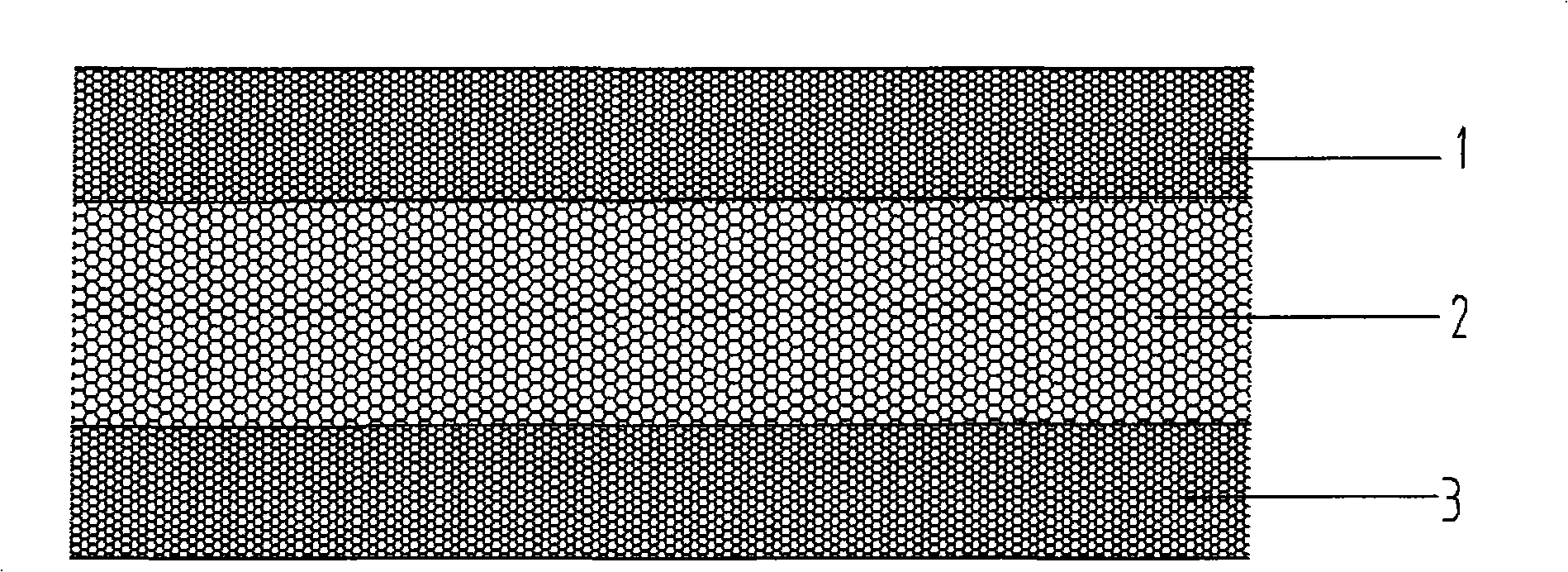

[0040] as attached figure 1 As shown, the preparation thickness is 3mm and the density is 50kg / m 3 The foam sheet with a thickness of 5mm and a density of 30kg / m 3 Foam sheets with a thickness of 5mm are combined in the middle of two layers of 3mm sheets, so that the thickness of the upper layer 1 is 3mm, the thickness of the middle layer 2 is 5mm, the thickness of the lower layer 3 is 3mm, the total thickness is 11mm, and the average density 40kg / m 3 The three-layer composite polyethylene foam sound insulation layer8.

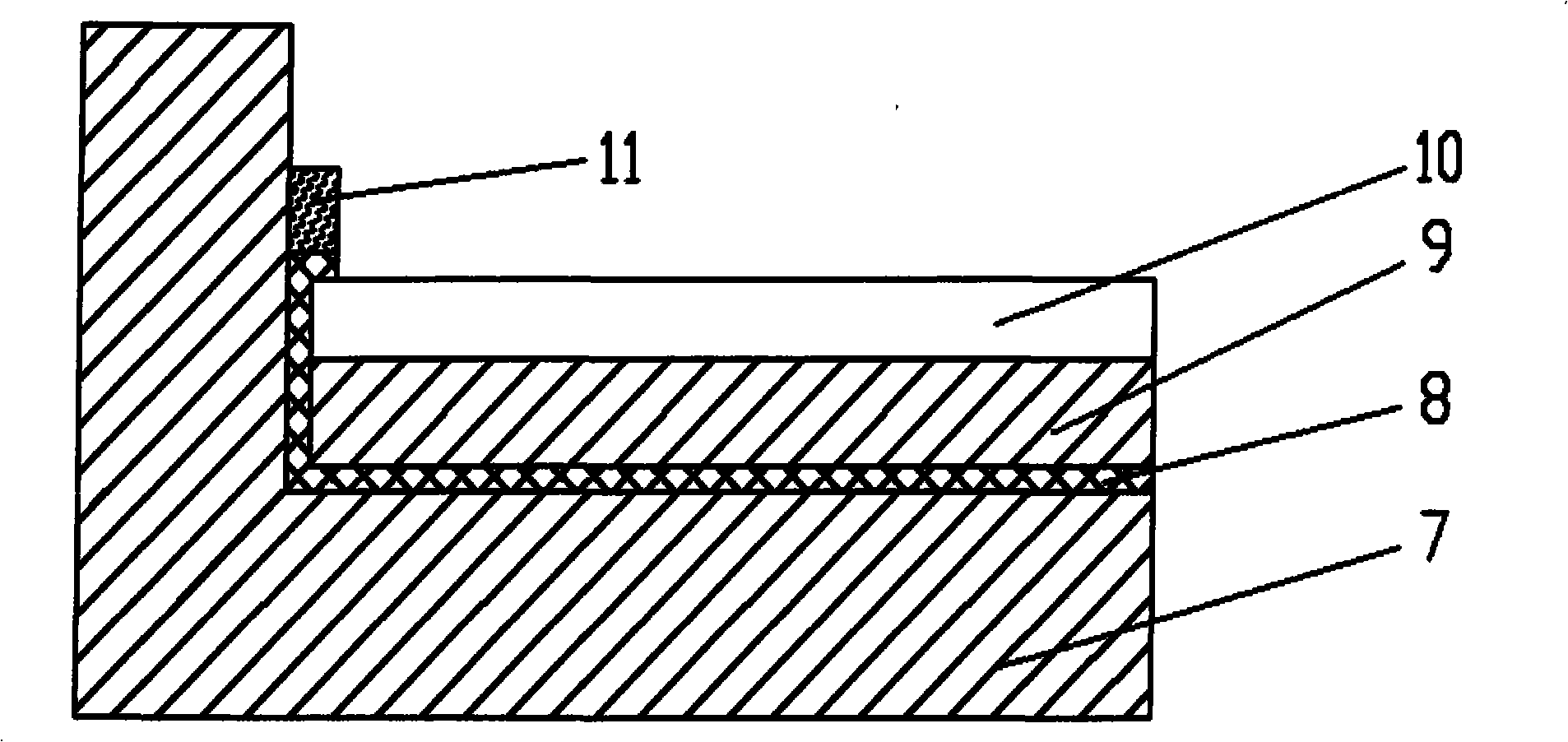

[0041]Construction method 1 is adopted during construction, and the specific structure is as follows image 3 Shown:

[0042] 1. Before the construction of the sound insulation material, the ground should be cleaned, and the sundries on the ground should be avoided as much as possible, which would cause damage to the sound insulation material;

[0043] 2. The sound insulation material should be trimmed in advance. If there is any defect, it should be cut ...

Embodiment 2

[0051] Through three extruders and a three-layer co-extrusion die, an unfoamed sheet of a certain thickness and width is obtained, and then heated and foamed to obtain a surface layer and a core layer with different thicknesses and densities.

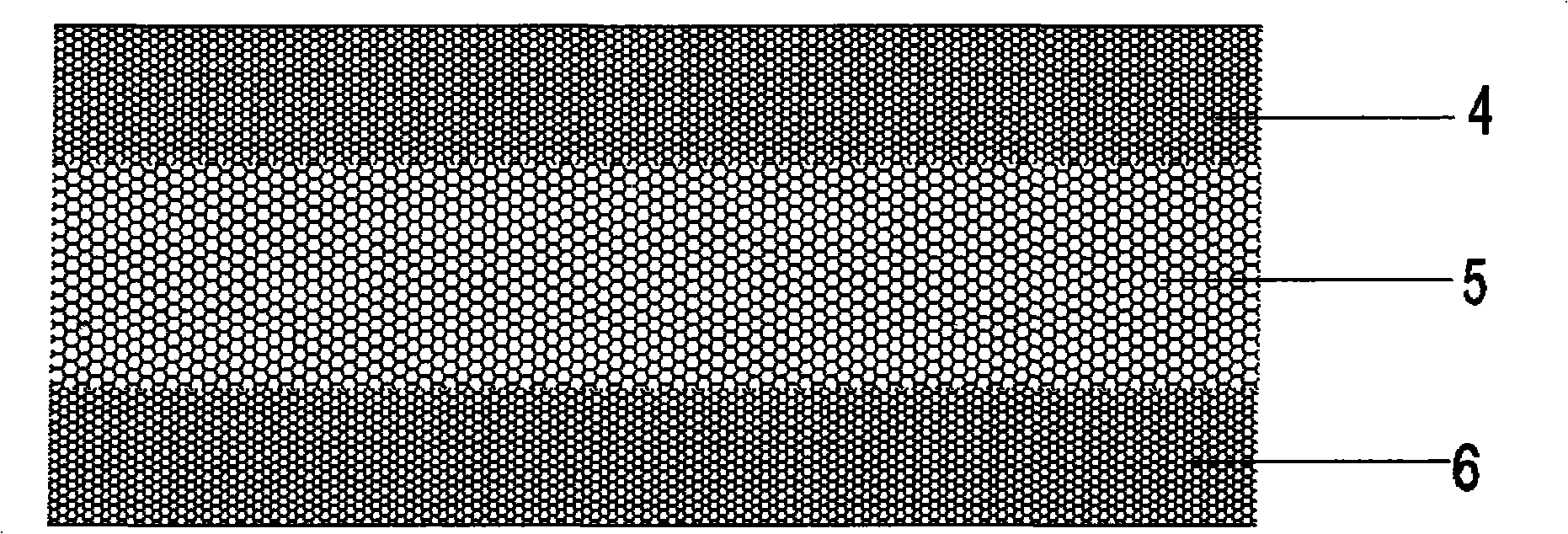

[0052] The structural schematic diagram of this embodiment is as attached figure 2 As shown, in the present embodiment, the foam material with a structure of upper and lower surface layers that is formed by one-time foaming is adopted, wherein the thickness of the upper surface layer 4 is 6mm, and the density is 100kg / m 3 ; The core layer 5 has a thickness of 8mm and a density of 50kg / m 3 ; The thickness of the hypocortex 6 is 6mm, and the density is 50kg / m 3 , the overall thickness is 20mm.

[0053] The specific construction method is to use the sound insulation layer to bypass the wooden floor or other decorative ground for the treatment of the skirting line, fix the skirting line on the wall, and press the lower surface of the ski...

Embodiment 3

[0055] Prepared with a thickness of 4mm and a density of 70kg / m 3 The foam sheet with a thickness of 7mm and a density of 40kg / m 3 The foam sheet with a thickness of 7mm is compounded in the middle of two layers of 4mm sheets, so that the thickness of the upper layer 1 is 4mm, the thickness of the middle layer 2 is 7mm, the thickness of the lower layer 3 is 4mm, and the total thickness is 15mm. Composite polyethylene foam sound insulation.

[0056] Concrete construction method is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

| Average density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com