Fuel oil injection method of ignition chamber direct-spraying petrol engine

A fuel injection and ignition chamber technology, applied in fuel injection control, mechanical equipment, engine control, etc., can solve the problems of difficult engine ignition, increased emissions, and unstable combustion, and achieve rapid and stable flame propagation, stable and reliable ignition, and The effect of reducing the mixture concentration considerations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

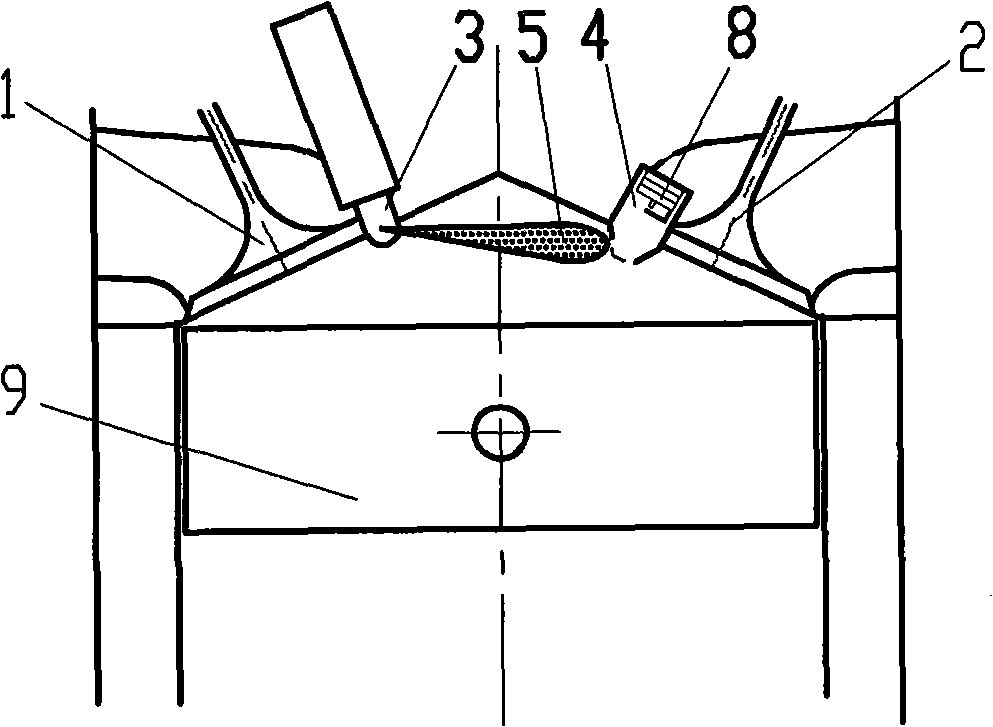

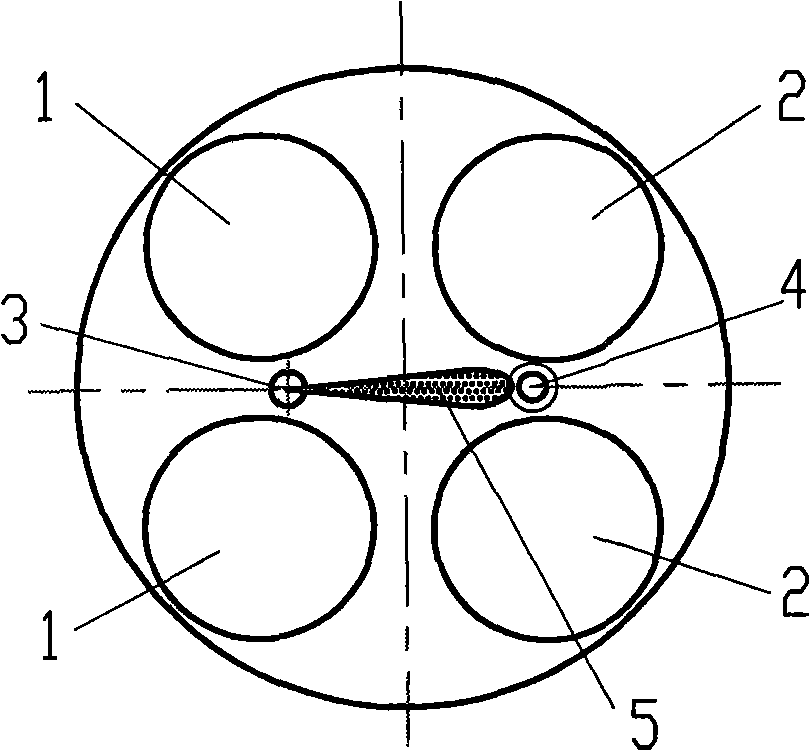

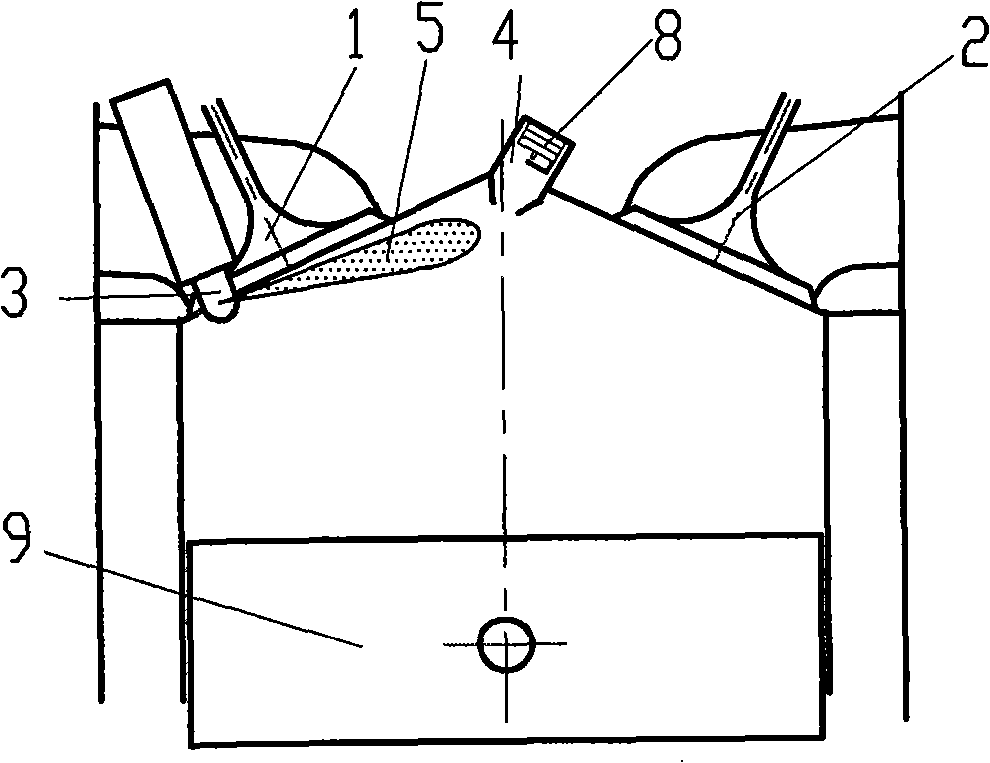

[0021] In the embodiment shown in the above drawings, an ignition chamber 4 is arranged on the cylinder head of the direct-injection gasoline engine, and a spark plug 8 is placed therein. The fuel injector is a multi-hole nozzle 3, and the center line of one of the nozzle holes points to the ignition chamber. 4 entrances. Combined with the airflow movement in the engine cylinder, the gasoline electronically controlled injection system is used to perform one or more injections during the period from the closing of the exhaust valve 2 of the engine to the compression top dead center. By selecting the appropriate injection timing, one injection is performed when the airflow is relatively weak Or more than one high-speed injection, each injection of a beam of oil is injected into the ignition chamber, and other oil beams enter the main combustion chamber; according to the working conditions, one or more low-speed injections can be performed when the airflow is relatively strong, be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com