Gas jet impact type revolving drum drying and curing integrated machine

A gas jet and impact technology, applied in non-progressive dryers, drying solid materials, heating to dry solid materials, etc., can solve the problems of uneven local heating, long drying time, waste of energy, etc., to reduce energy consumption Consumption, high heat utilization rate, strong adaptability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

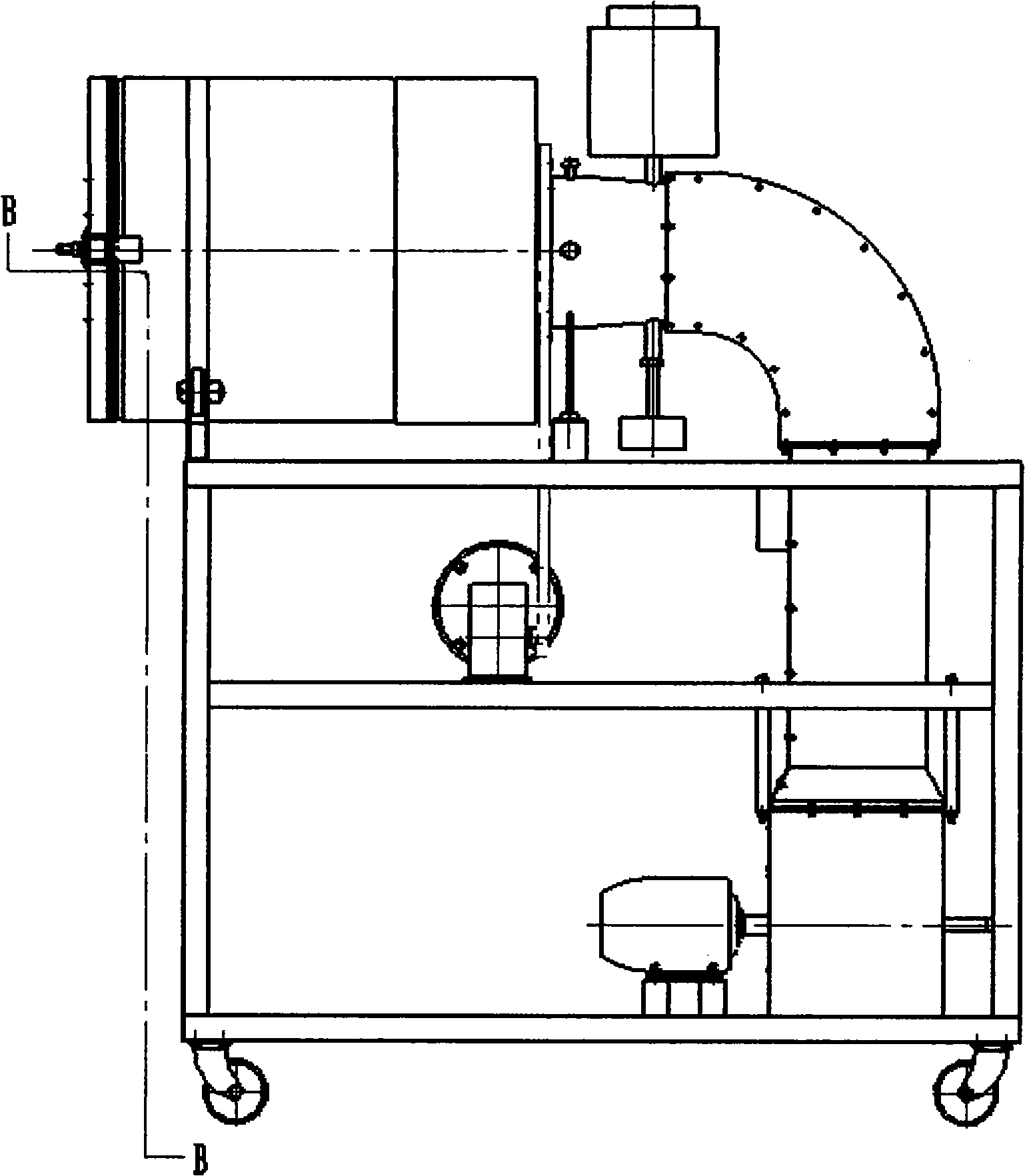

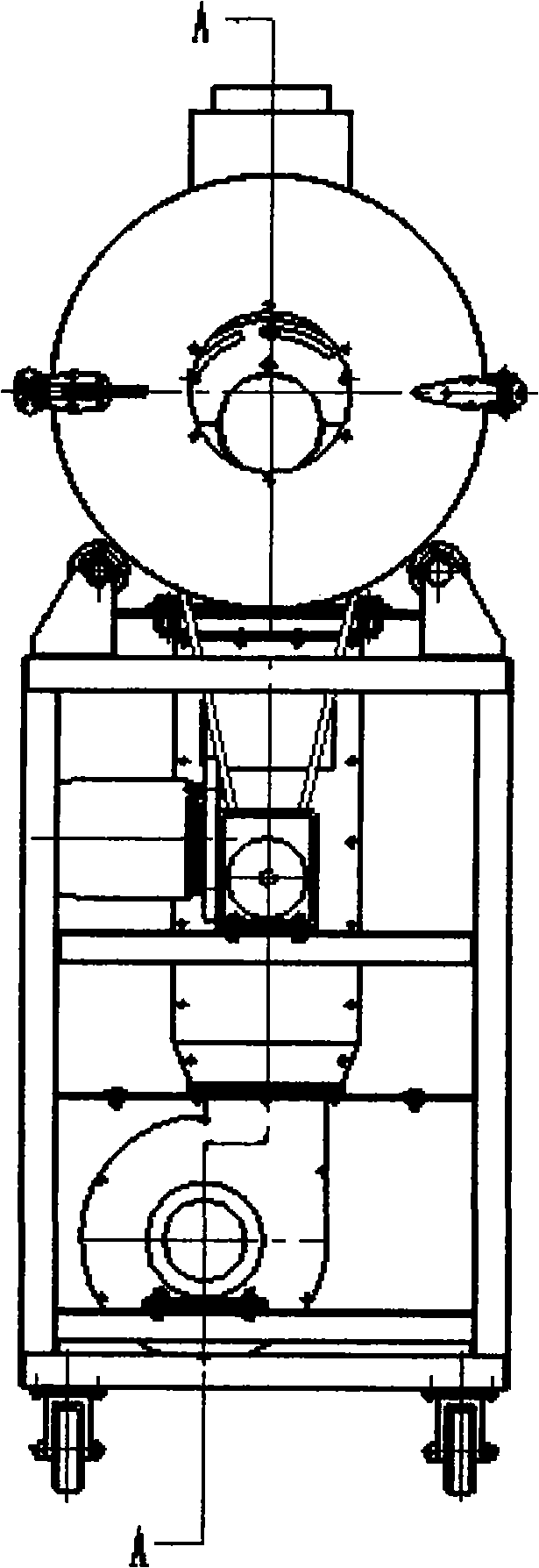

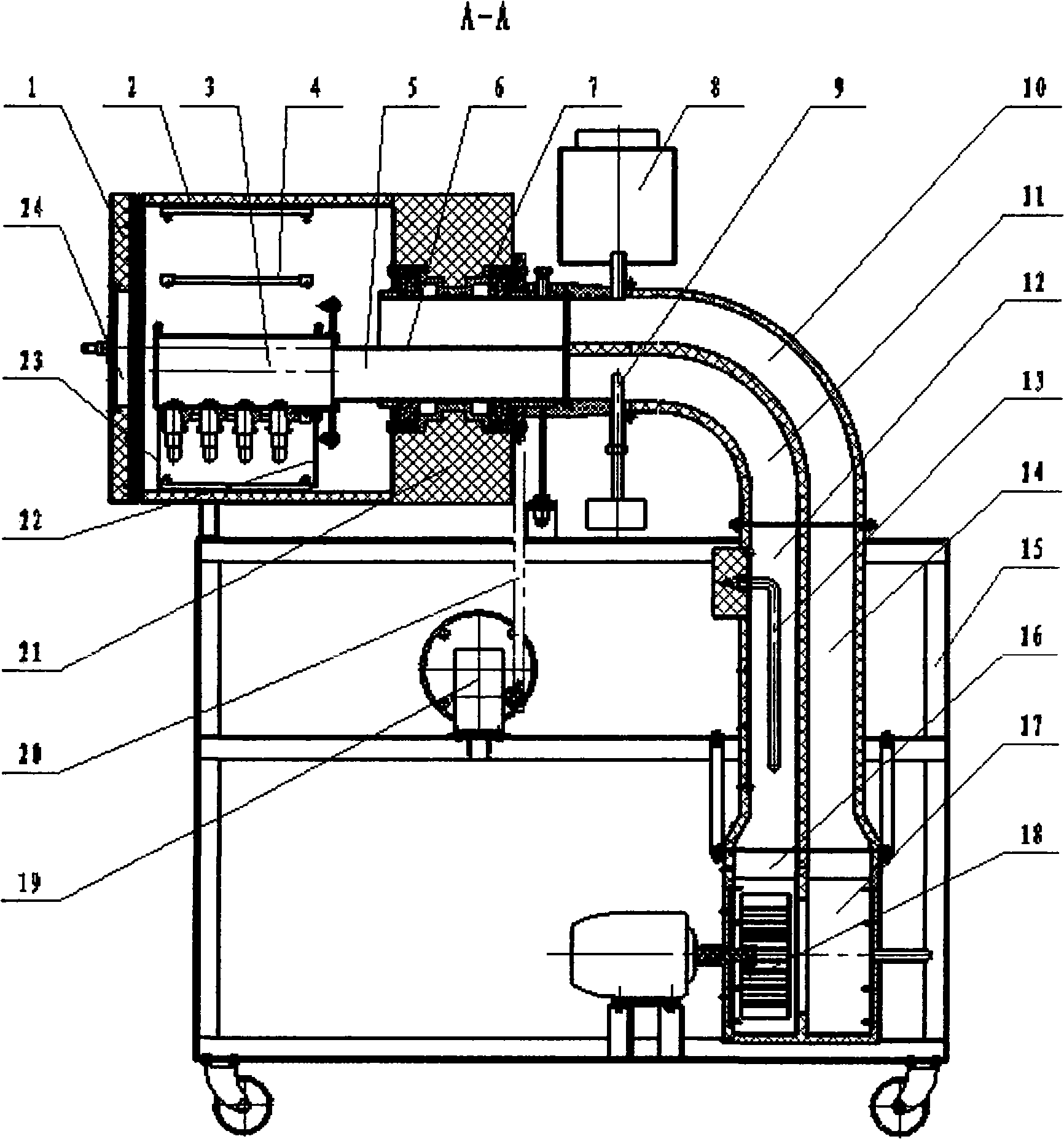

[0025] The gas jet impingement drum drying and baking integrated machine designed by the present invention includes a cylinder cover 1, a cylinder body 2, an air distribution chamber 3, a central pipe for air inlet and return air 5, a bearing and a bearing sleeve mechanism 7, and an exhaust device 8 , temperature and humidity sensor 9, return air elbow section 10, air inlet elbow section 11, air inlet straight pipe section 12, return air straight pipe section 14, heating device 13, frame 15, air inlet volute 16, return air volute 17. Fan mechanism 18, speed reducer 19, chain transmission mechanism 20, supporting wheel mechanism 25.

[0026] An exhaust device 8 is arranged above the return air elbow section 10 for regulating the moisture content of the air in the drying and baking machine.

[0027] The installation angle α of the spray pipe on the air distribution chamber 3 can be 45-135 degrees with the horizontal plane.

[0028] The angle β between the middle row of nozzles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com