Early warning monitoring and condition constructing method and device for component surface failure

A technology of early warning monitoring and construction methods, applied in the direction of material resistance, etc., can solve the problems of high cost, complex special equipment, low accuracy, etc., and achieve the effect of simple operation procedures, simple preparation process, and good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

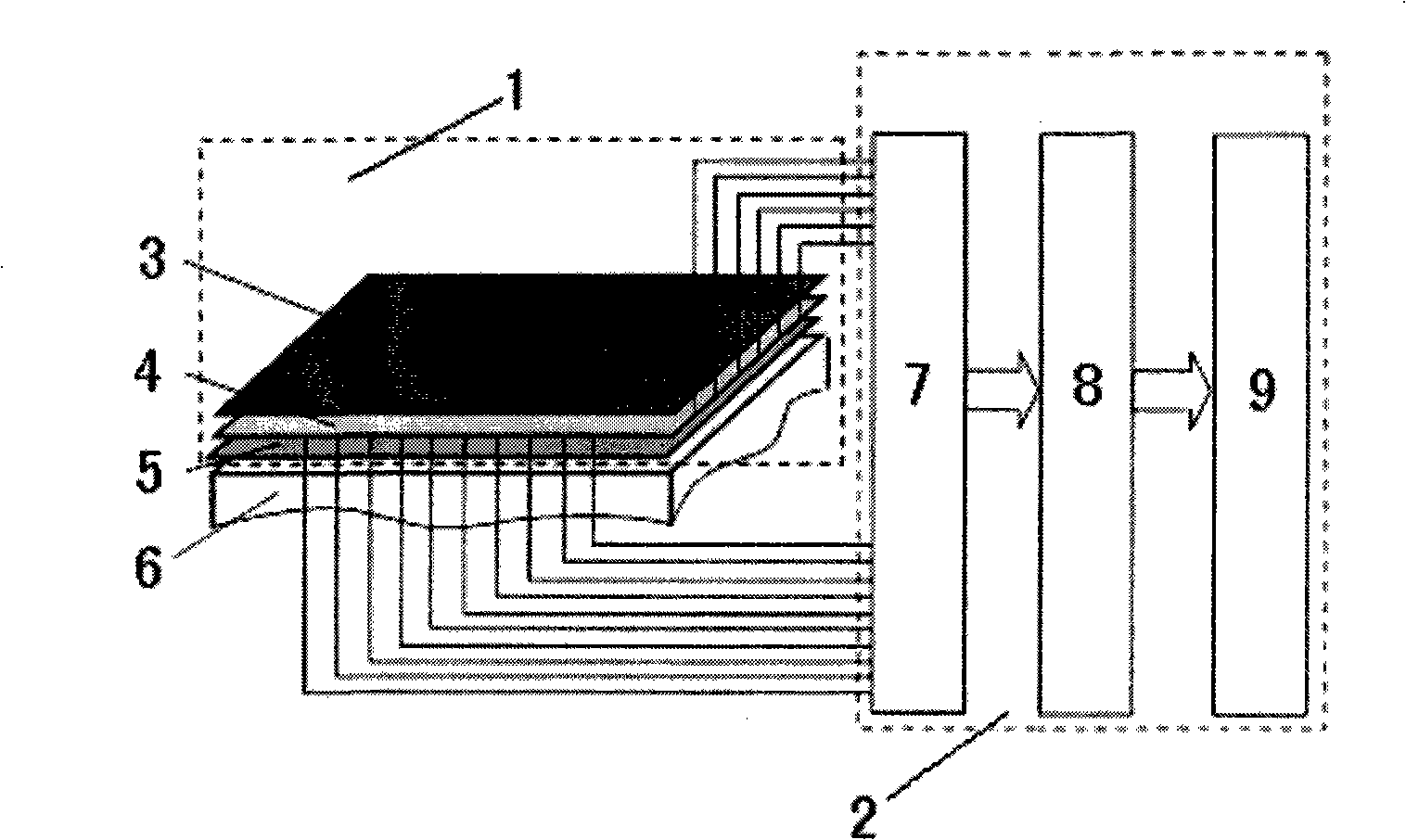

[0034] Embodiment: Condition construction method for early warning monitoring of component surface failure in the present invention

[0035] Step 1 Prepare the driver layer:

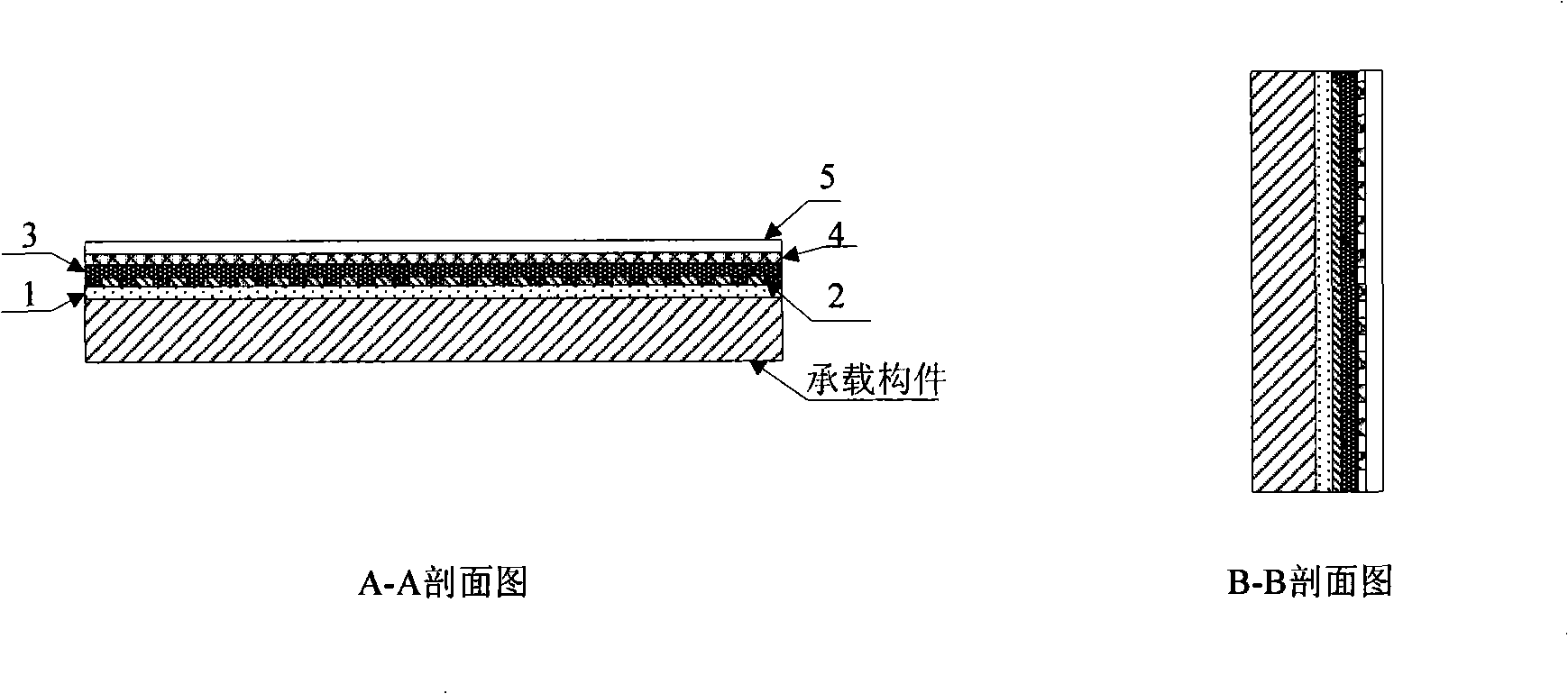

[0036] Select 45# steel plate with a thickness of 4mm as the base material, and make it a standard sample with a length of 100mm, a width of 50mm, and a thickness of 3.5mm through shearing and grinding. The sample is subjected to a series of pretreatments such as degreasing and rust removal, surface activation, phosphating, cleaning, etc., and then a layer of epoxy resin is sprayed on the surface of the sample by electrostatic powder spraying technology as the driving layer, with a thickness of about 20 μm.

[0037] Step 2 Prepare the network bridge layer:

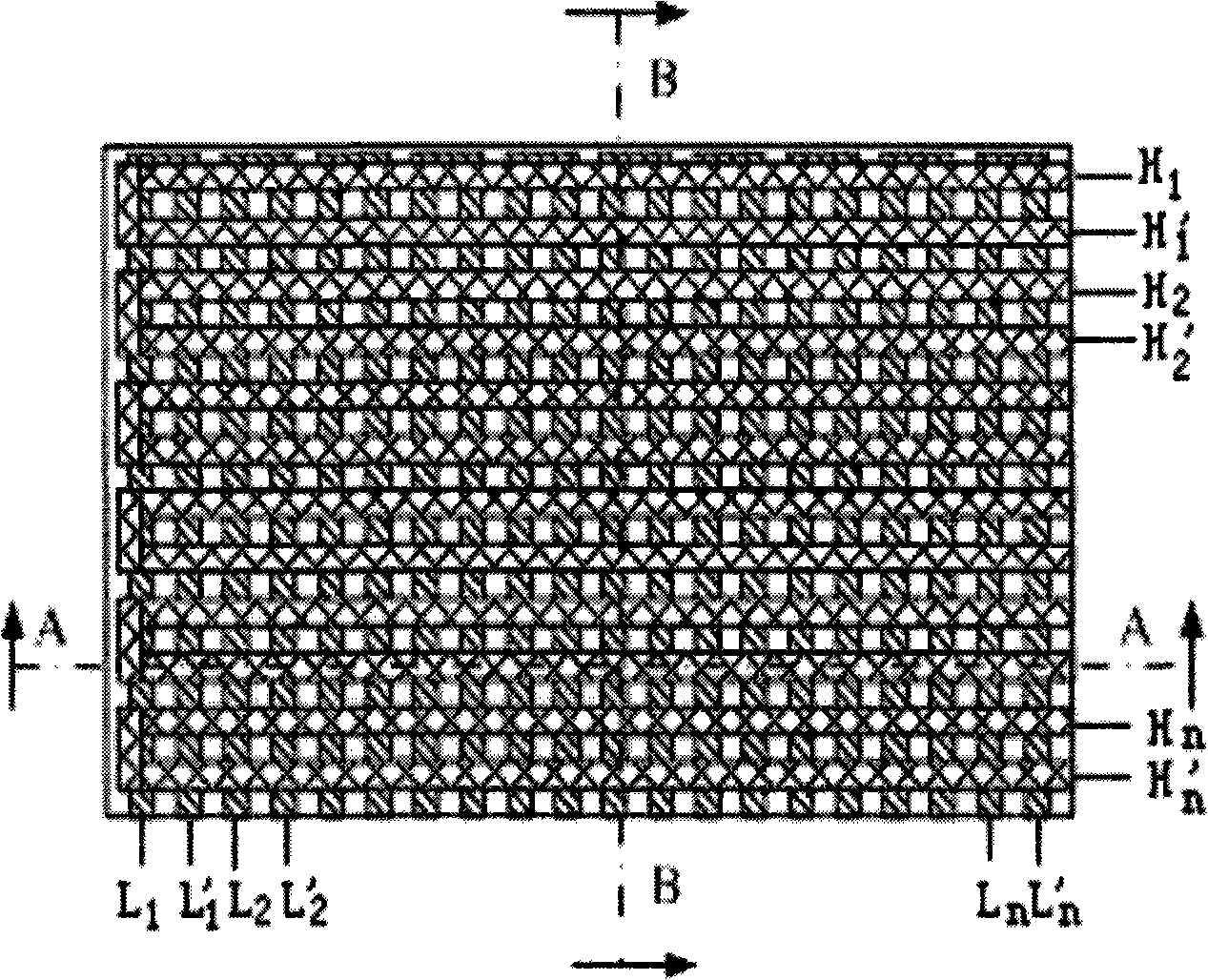

[0038] Cut the 30μm thick copper foil into the size of the sample, and use the method of integral pressing to make a "шшш" grid-shaped metal copper sheet, in which the fence and grid are both 1.5mm. Then two grid-shaped metal sheets are overlapped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com