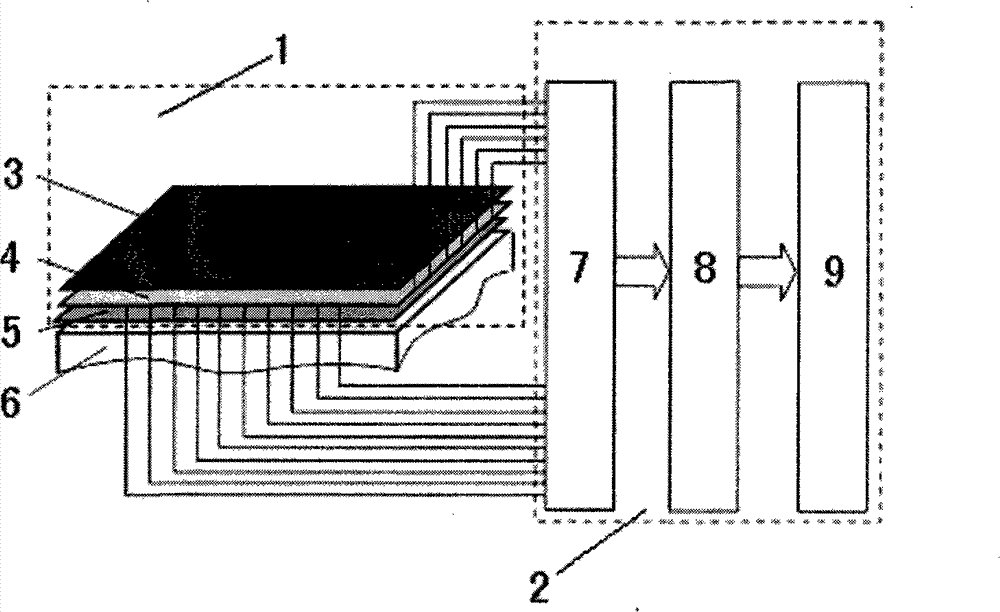

Early warning monitoring and condition constructing method and device for component surface failure

A technology of early warning monitoring and construction method, applied in the direction of material resistance, etc., can solve problems such as unfavorable on-site operation, high cost, complex special equipment, etc., and achieve the effect of avoiding major accidents, simple operation procedures, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

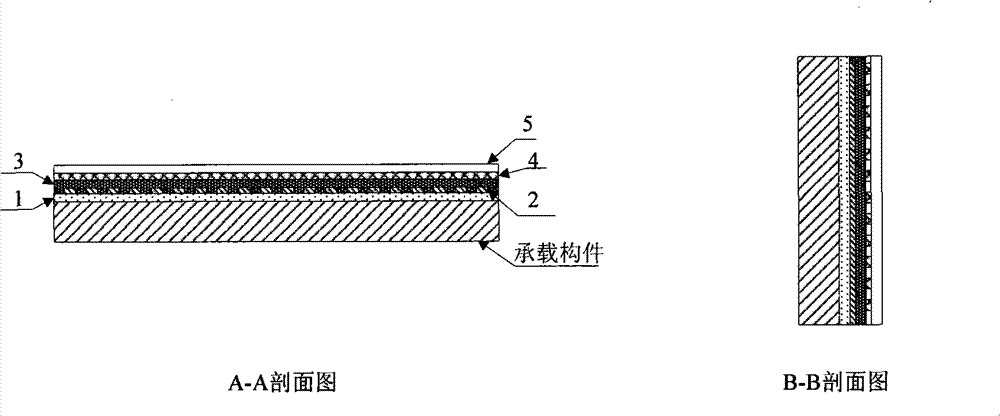

[0033] Embodiment: Condition construction method for early warning monitoring of component surface failure in the present invention

[0034] Step 1 Prepare the driver layer:

[0035] Select 45# steel plate with a thickness of 4mm as the base material, and make it a standard sample with a length of 100mm, a width of 50mm, and a thickness of 3.5mm through shearing and grinding. The sample is subjected to a series of pretreatments such as degreasing and rust removal, surface activation, phosphating, cleaning, etc., and then a layer of epoxy resin is sprayed on the surface of the sample by electrostatic powder spraying technology as the driving layer, with a thickness of about 20 μm.

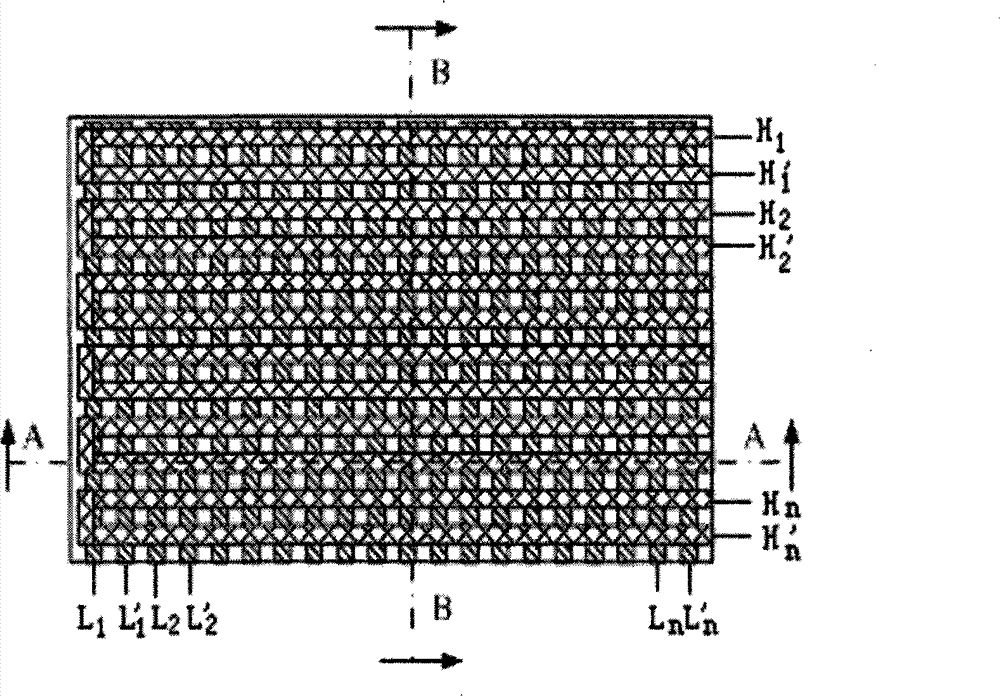

[0036] Step 2 Prepare the network bridge layer:

[0037] Cut the 30μm thick copper foil into the size of the sample, and use the method of overall pressing to make a "Ш Ш Ш" grid-shaped metal copper sheet, in which the fence and grid are both 1.5mm. Then two grid-shaped metal sheets are overlapped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com