Gas-chromatography detection method used for power transformer oil

A power transformer and gas chromatography technology, applied in the field of gas chromatography detection of power transformer oil detection, can solve the problems of being difficult to be widely accepted by domestic users, expensive, and different, and achieve overall stability and improve the repeatability of test data. , excellent cost performance, improve the effect of comprehensive economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

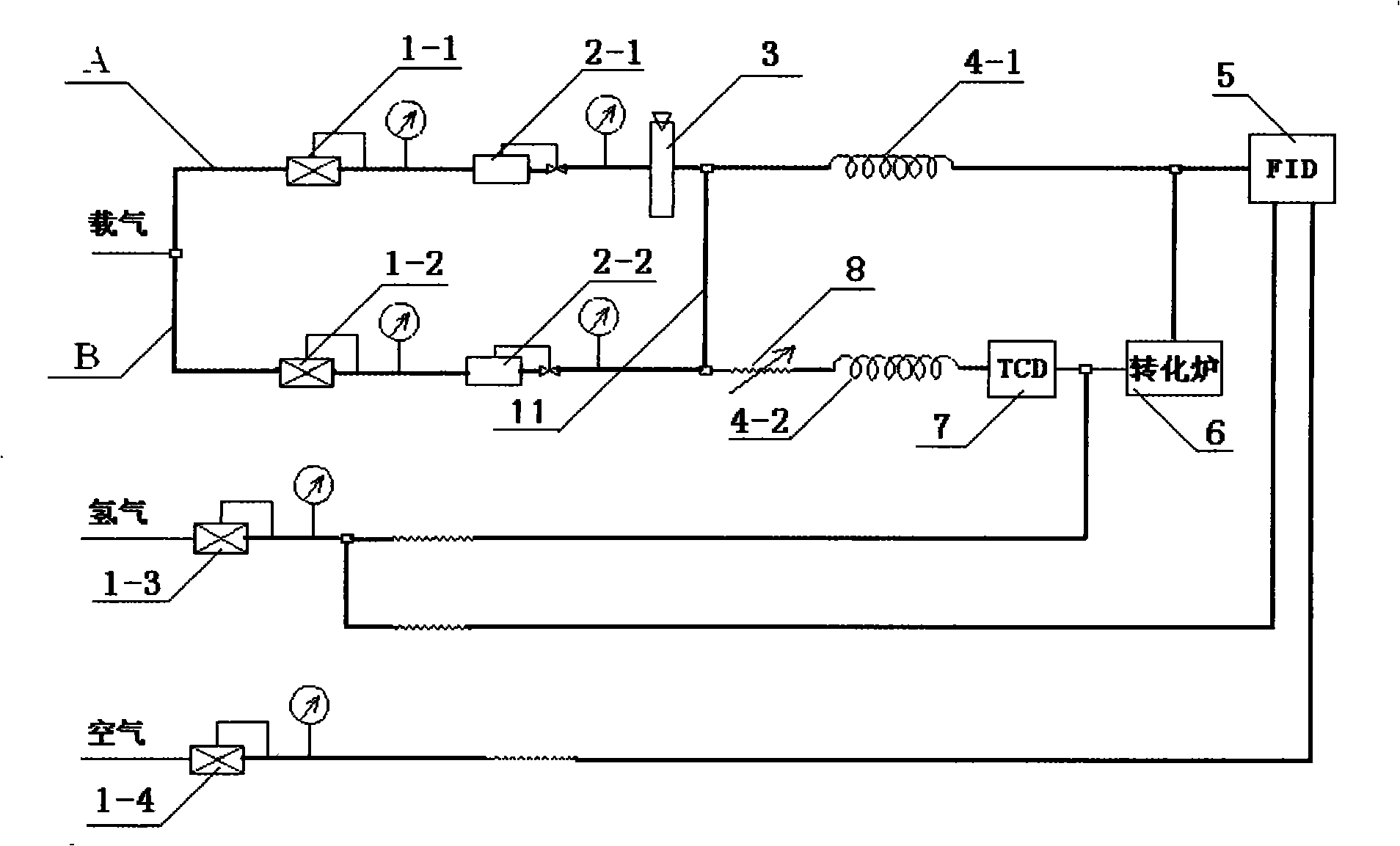

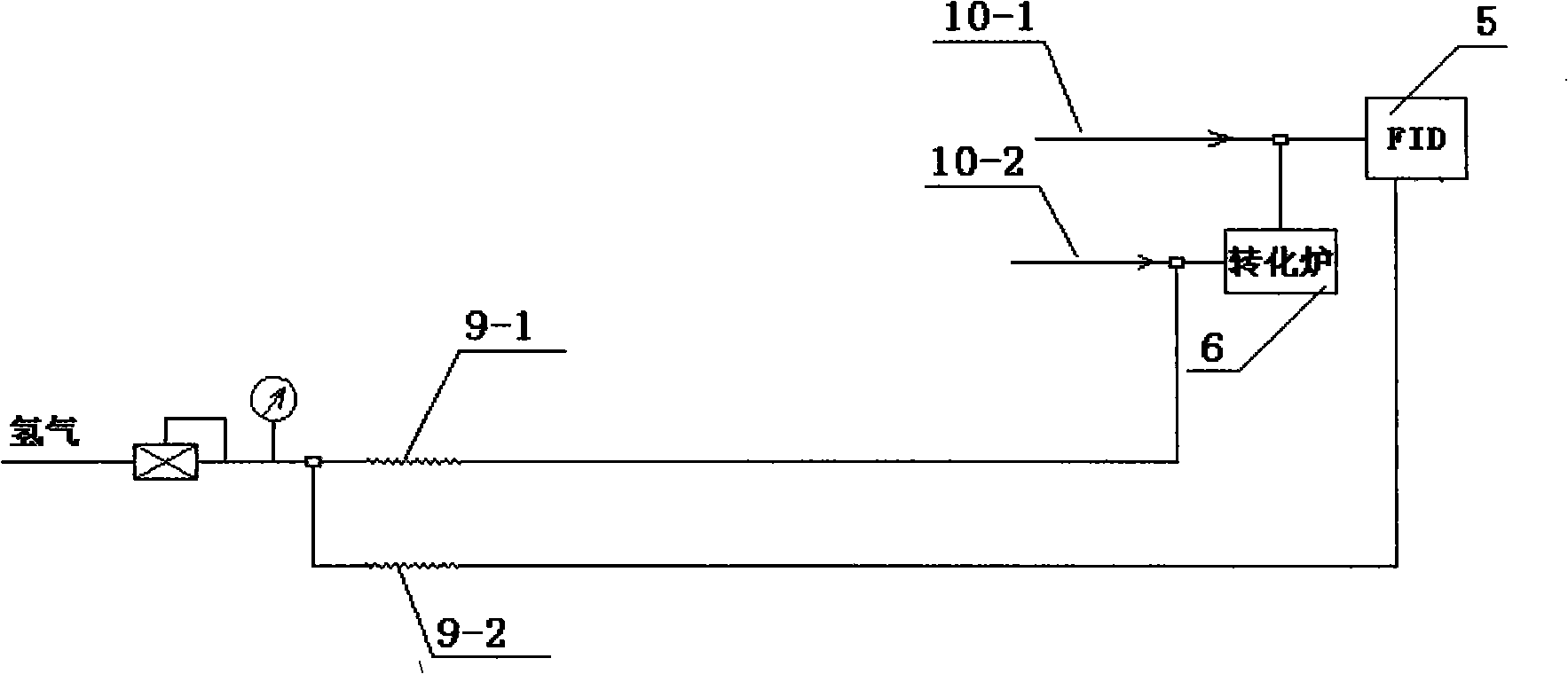

[0015] Such as Figure 1-2 The gas chromatographic detection method shown for the detection of power transformer oil is a creative improvement on the detection process of the special gas chromatograph for power transformer oil commonly used in China. The improvement of this detection method is reflected in the following three aspects:

[0016] First, the method of forced diversion is adopted

[0017] An auxiliary carrier gas circuit B is installed in the carrier gas inlet pipeline of the detection system. By means of forced diversion, according to the gas flow rate of the main carrier gas circuit, the gas flow rate of the auxiliary carrier gas circuit and the needle valve installed on the auxiliary carrier gas circuit 8, etc. to adjust, so that the tested sample is divided into two parallel connection in the main carrier gas circuit and the auxiliary gas circuit for the analysis of hydrocarbons and the analysis of H 2 , CO, CO 2 In the component chromatographic column, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com