Cold accumulation cooling-down type solar battery component

A technology of solar cell components and solar cells, applied in electrical components, circuits, photovoltaic power generation, etc., to achieve the effects of reducing thermal resistance, improving conversion efficiency, and improving solar conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings.

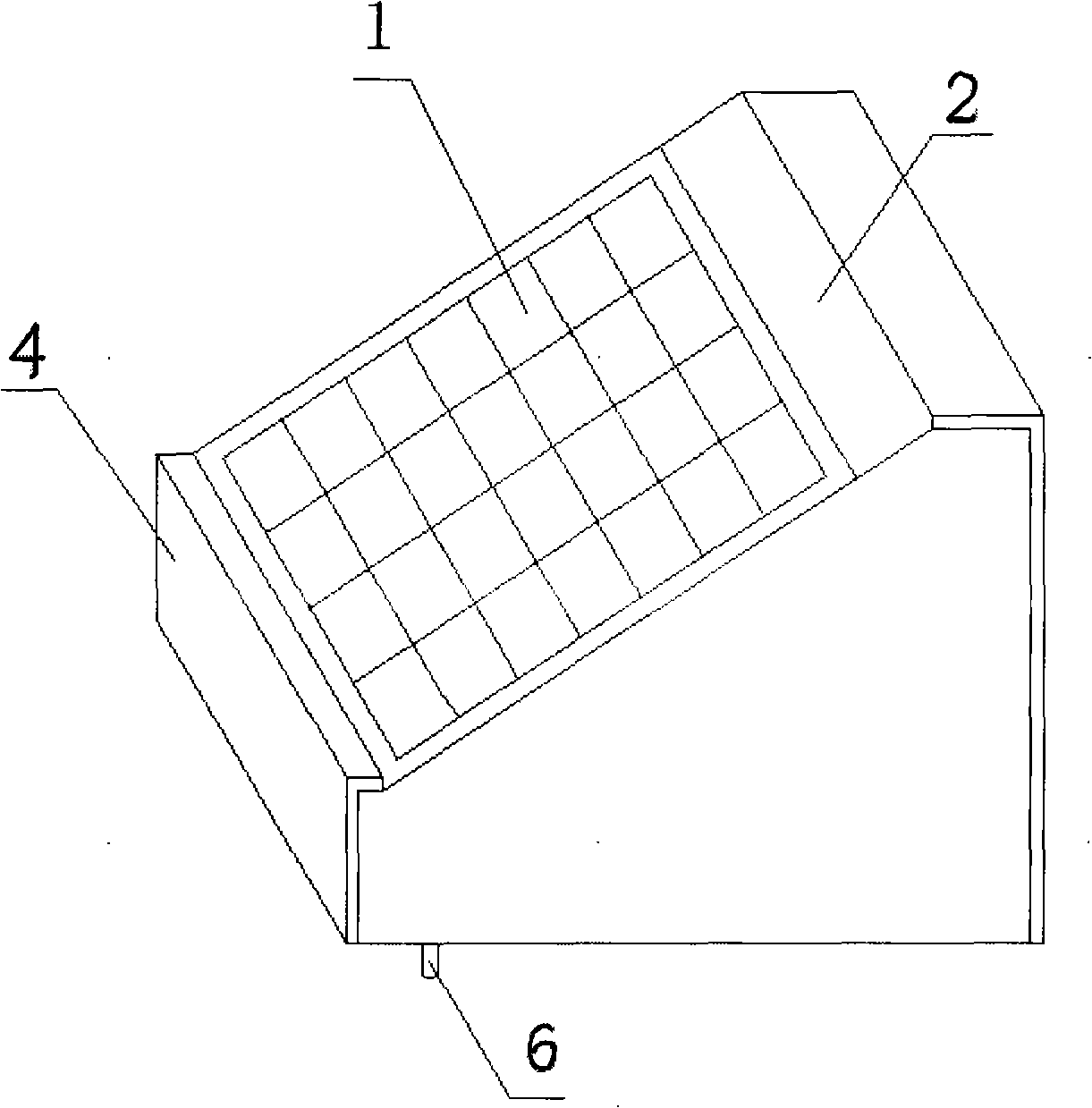

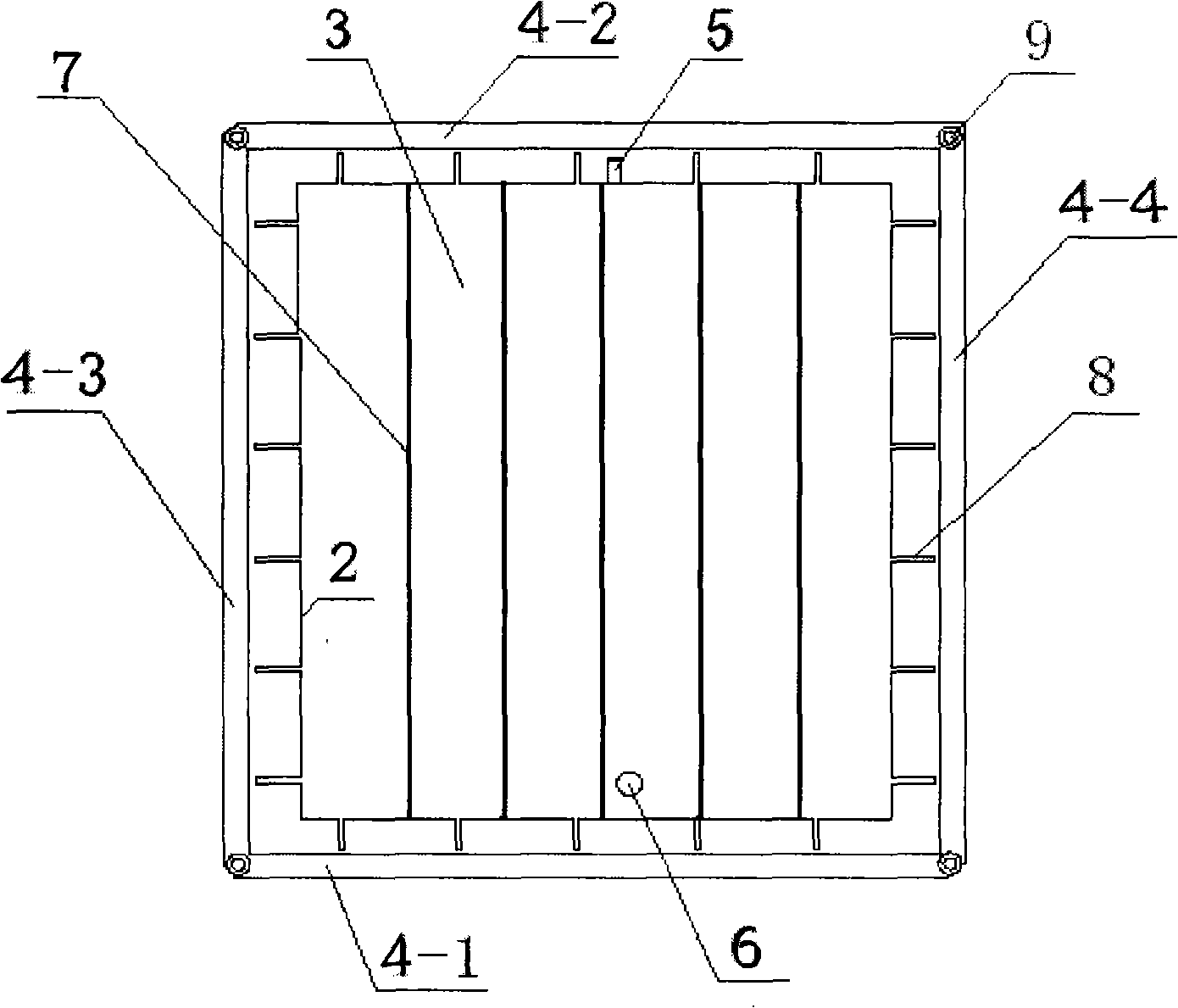

[0011] see figure 1 , The cold storage and cooling type solar cell assembly is composed of a solar cell packaging assembly 1, a cooling medium container 2, a cooling medium 3 contained in the cooling medium container, and an automatic opening and closing heat preservation device 4 surrounding the cooling medium container.

[0012] The solar cell encapsulation component 1 is encapsulated by the conventional process, that is, the "sandwich" method of solar glass, EVA, solar cells, EVA, and the back sheet is vacuum-heated and laminated on the laminator, and the back sheet is anodized and insulated. Metal material, preferably aluminum alloy plate or copper plate can be used. The solar cell encapsulation assembly is obliquely installed above the cooling medium container, the inclination angle is 20°-50°, preferably the geographic latitude of the place of use.

[0013] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com