Encapsulation of silicon substrate LED

An encapsulation method and technology of silicon substrate, which are applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing the transparency of epoxy resin and increasing the cost, and achieve the effects of low cost, low defective rate and optimized operation mode.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention provides a silicon substrate LED packaging method.

[0023] The embodiments of the present invention take an LED chip made of gallium nitride material as an example. Gallium nitride is the luminescent material for blue and green LED chips, and an 8mil blue chip is used to produce white light, and the height of the chip containing the silicon substrate is 200 μm. The chip electrode is a single electrode structure.

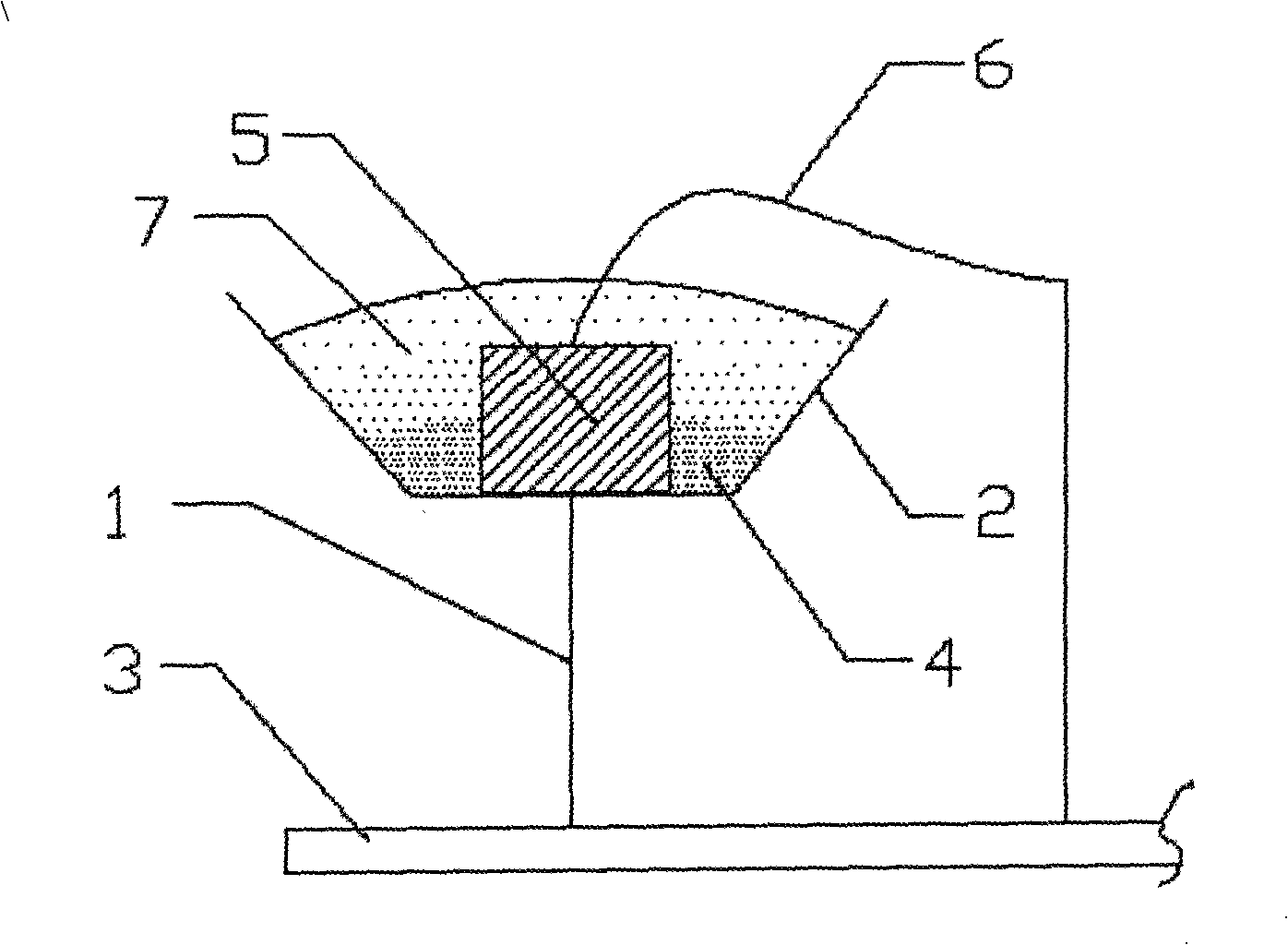

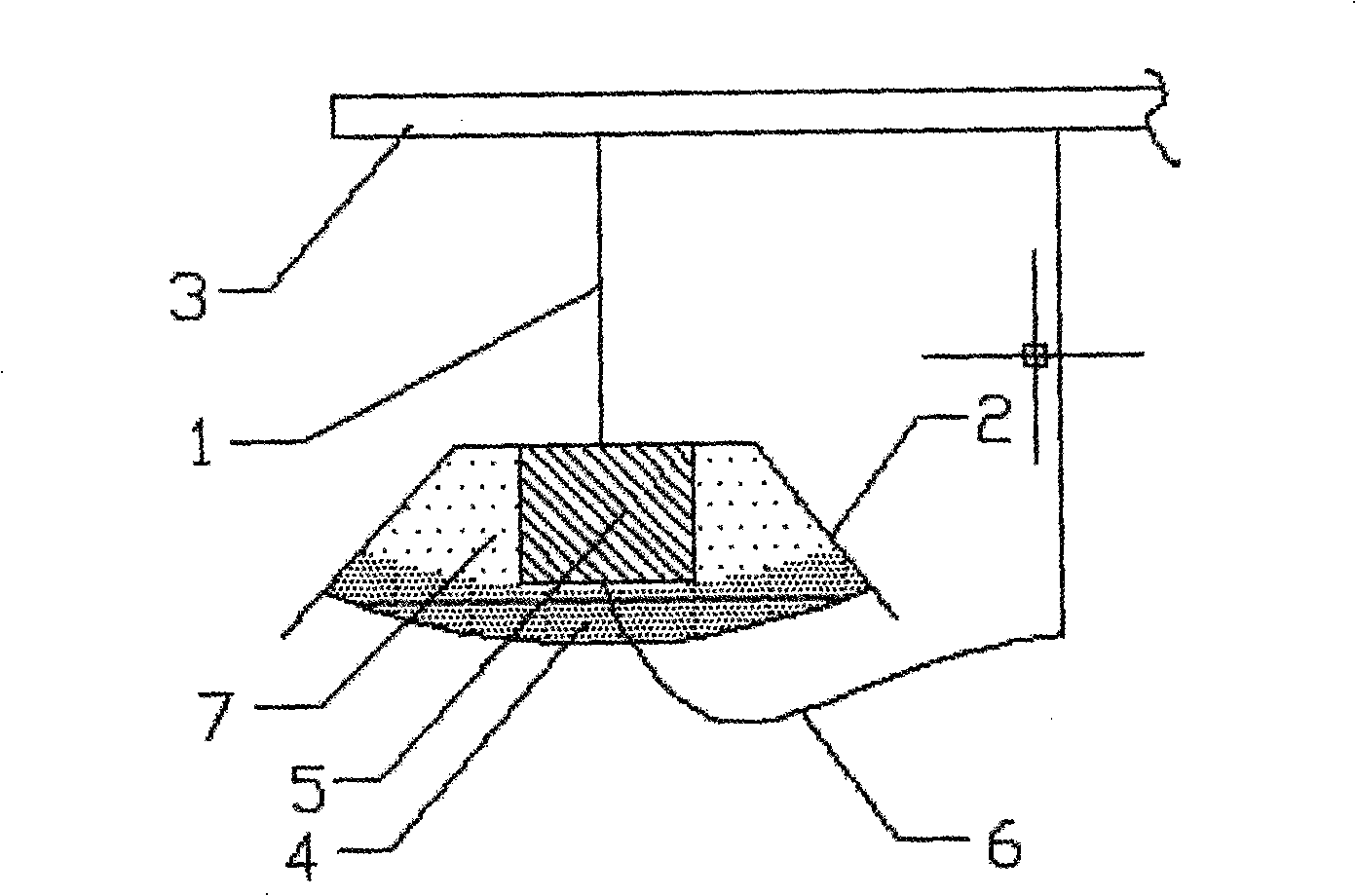

[0024] Test one, see figure 1 , made according to traditional techniques:

[0025] Wire bonding, solder wire 6, connect the electrode of the chip 5 to the pin of the bracket 1; mix the glue, mix the phosphor powder 4 in the transparent epoxy resin 7; dispense glue, fill the epoxy resin mixture into the reflector 2 In the process, the chip 5 is covered to form a lens shape that is conducive to astigmatism; for curing, the LEDs that have been glued are placed in a curing furnace for baking and curing. The curing temperature is 130 degrees Celsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com