Steel finned tubular radiator nozzle and header automatic soldering technique as well as fixture

A technology of automatic welding and finned tubes, applied in the direction of manufacturing tools, welding equipment, welding equipment, etc., can solve the problems of manual arc welding welding quality instability, low work efficiency, etc., to reduce labor intensity and work difficulty, improve work efficiency, The effect of improving the high-quality product rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

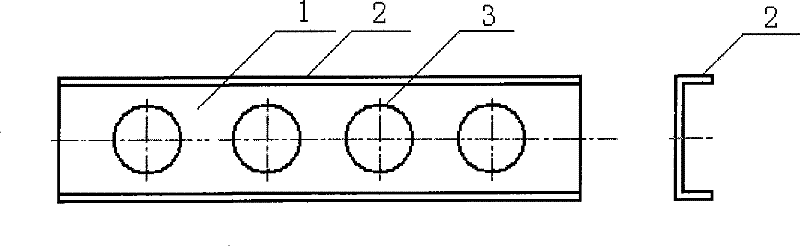

[0015] Embodiment 1: ① Carry out fine punching to the baffle. Such as figure 1 As shown, the edge 2 of the baffle 1 is tilted upwards in a "[" shape, and a nozzle 3 is provided on the baffle. Keep the hole spacing and relative position of each hole consistent.

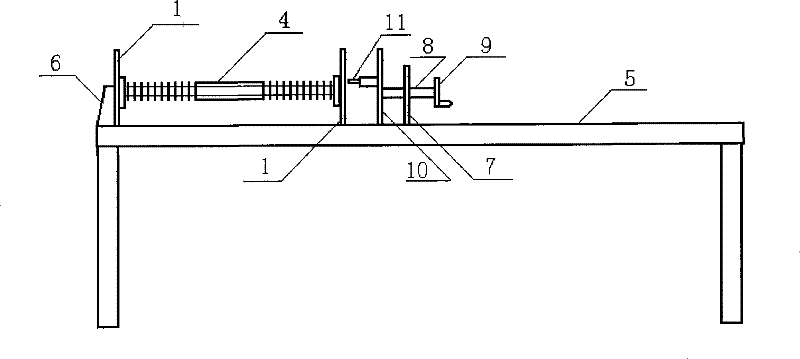

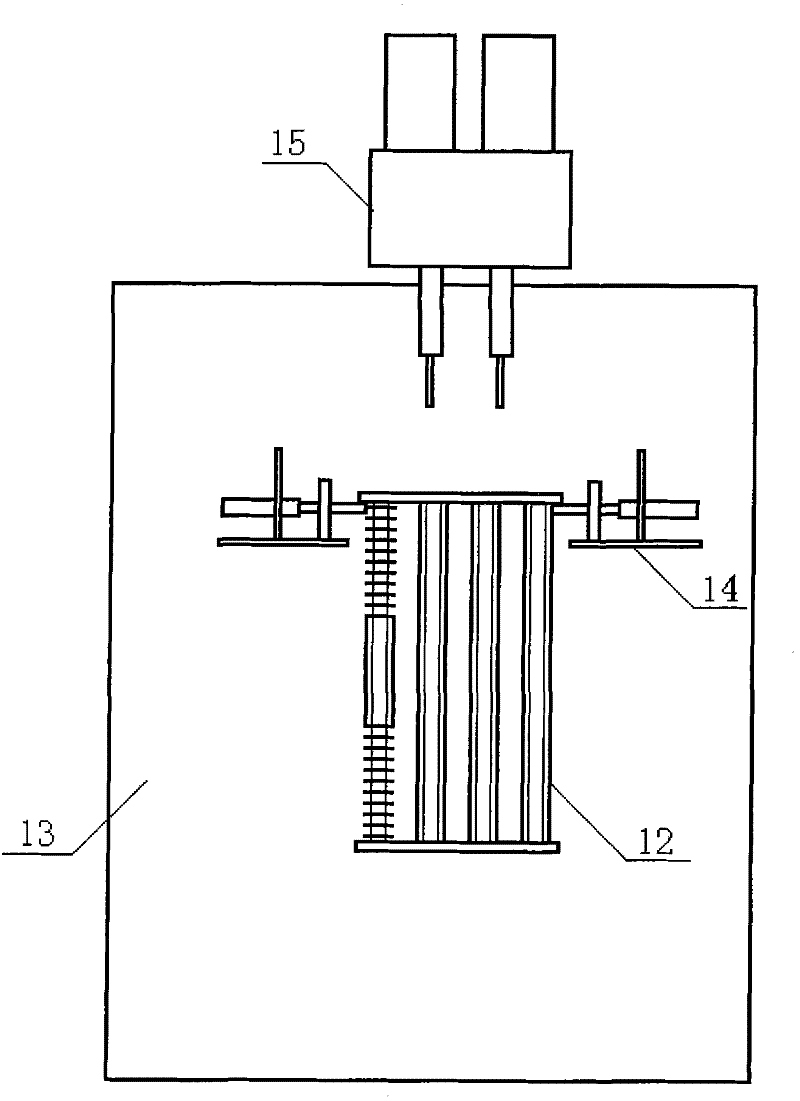

[0016] ②Inner core assembly. The finned tube single tube and the baffle are assembled into one body with the inner core assembly equipment, which can effectively guarantee the accuracy requirements of the assembly size. Such as figure 2 As shown, the front and rear ends of the tube 4 with steel fins are installed in the nozzle 3 of the baffle 1 respectively, and the baffle at the front end is placed on the table top 5 and is blocked by a fixed block 6 arranged on the table top. A fixed plate 7 is arranged on the desktop, and a hole is arranged on the fixed plate, and the shaft 8 passes through the hole, the shaft can rotate in the hole, and the shaft can also be fixed by the bearing; the rear end of the shaft is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com