Combined paper making machine for electrolytic capacitor paper

A technology of electrolytic capacitor paper and paper machine, which is applied in the direction of paper machine, paper making, textile and paper making, etc. It can solve the problem that electrolytic capacitor paper cannot meet the requirements of high tightness and high absorption at the same time, and achieves simple structure, low loss performance, The effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

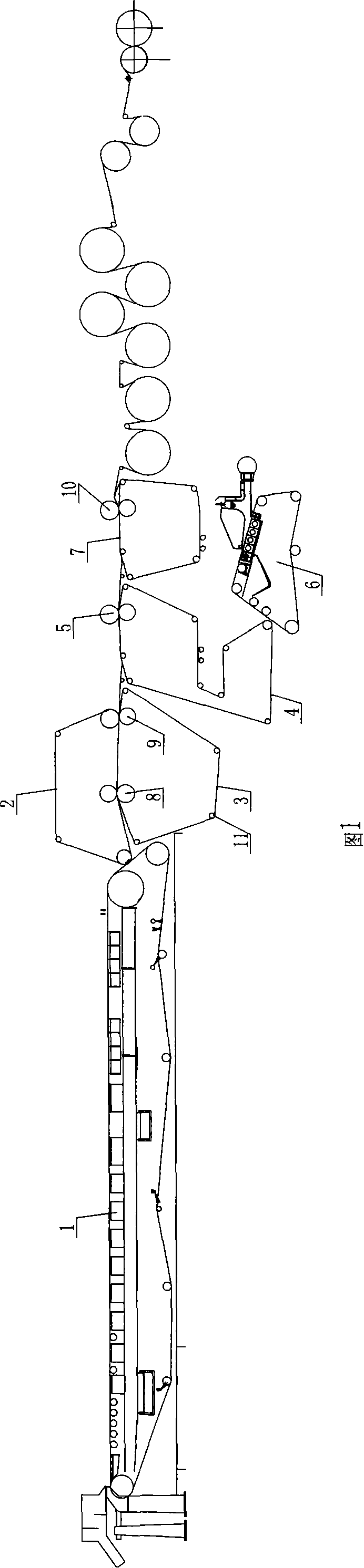

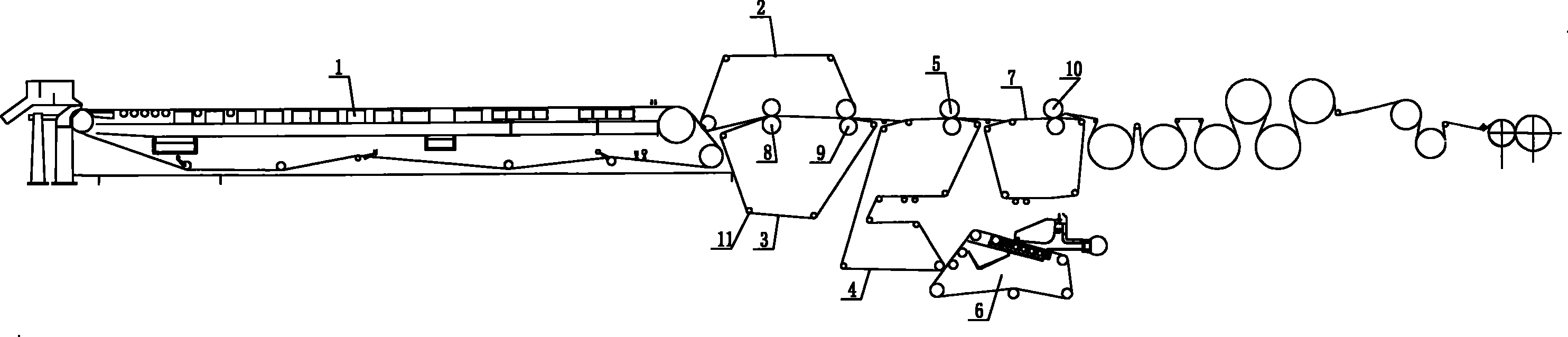

[0013] A combined paper machine for electrolytic capacitor paper as shown in Figure 1, the combined paper machine is composed of fourdrinier paper machine 1 for pressure-resistant layer papermaking and inclined wire paper machine 6 for absorption layer papermaking The fourdrinier paper machine 1 and the inclined wire paper machine 6 are connected by a conveying compound device, and the conveying compound device is connected with a drying cylinder, and the composite paper dried by the drying cylinder is rolled into a reel.

[0014] As shown in FIG. 1 , the conveying composite device includes an upper felt 2 , a lower felt 3 , an inclined wire felt 4 , a conveying felt 7 , a rotating roll 11 , a primary press roll 8 , a secondary press roll 9 and a composite roll 5 . The upper felt 2, the lower felt 3 and the inclined wire felt 4 are respectively arranged on the rotating roller 11 and driven by the rotating roller 11. The upper felt 2 is connected with the fourdrinier paper mach...

Embodiment 2

[0018] With the combined paper machine papermaking of electrolytic capacitor paper described in embodiment 1, the paper pulp of the pressure-resistant layer paper of electrolytic capacitor paper adopts wood pulp, beating degree is 67 ° SR, and wet weight is 5.6g, and the paper pulp of absorbing layer paper uses pineapple Hemp pulp, the degree of beating is 23°SR, and the wet weight is 27g. The paper pulp of the pressure-resistant layer paper is made by fourdrinier paper machine 1, and the paper pulp of the absorption layer paper is made by inclined wire paper machine 6. The pulp fiber of the pressure-resistant layer and the pulp fiber of the absorption layer are hung on the polyester net, respectively. After passing through the papermaking felt, it is composited and formed on the composite roll 5 to form composite pulp fibers. After the composite pulp fiber is separated from the felt, it enters the drying cylinder for drying treatment, and the dried paper is wound on the reel ...

Embodiment 3

[0021] With the combined paper machine papermaking of electrolytic capacitor paper described in embodiment 1, the paper pulp of the pressure-resistant layer paper of electrolytic capacitor paper adopts wood pulp, beating degree is 93 ° SR, and wet weight is 3.3g, and the paper pulp of absorbing layer paper uses sword Pulp, beating degree is 23 ° SR, wet weight 19g. The paper pulp of the pressure-resistant layer paper is made by fourdrinier paper machine 1, and the paper pulp of the absorption layer paper is made by inclined wire paper machine 6. The pulp fiber of the pressure-resistant layer and the pulp fiber of the absorption layer are hung on the polyester net, respectively. After passing through the papermaking felt, it is composited and formed on the composite roll 5 to form composite pulp fibers. After the composite pulp fiber is separated from the felt, it enters the drying cylinder for drying treatment, and the dried paper is wound on the reel to obtain the finished el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com