Cabinet, radiating device and method for installing the radiating device

A heat dissipation device and chassis technology, applied in cooling/ventilation/heating transformation, electrical components, metal casings, etc., can solve the problems of high production cost, cost increase, and high cost of refrigeration chips, and achieve low cost, enhanced heat dissipation effect, and processing simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

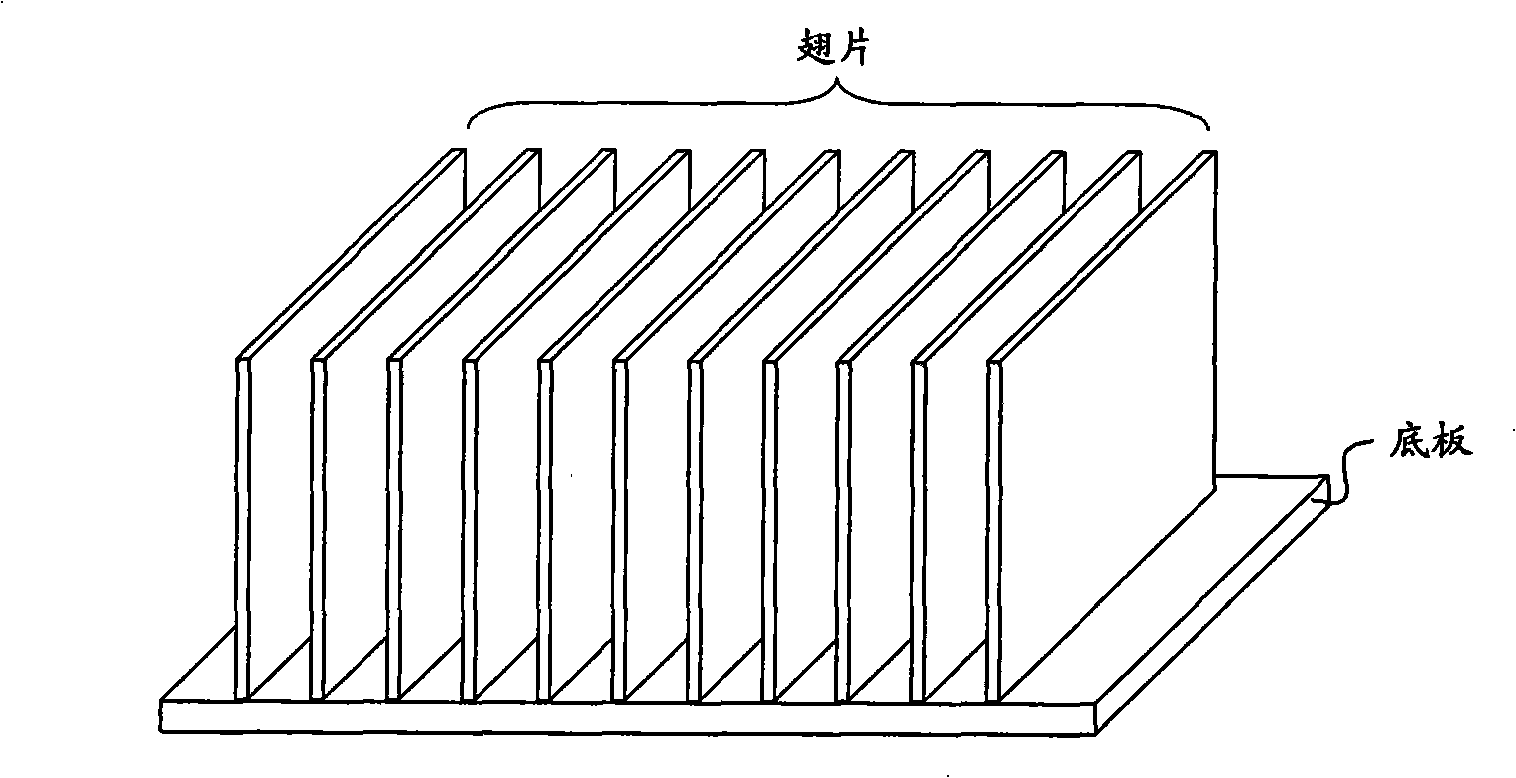

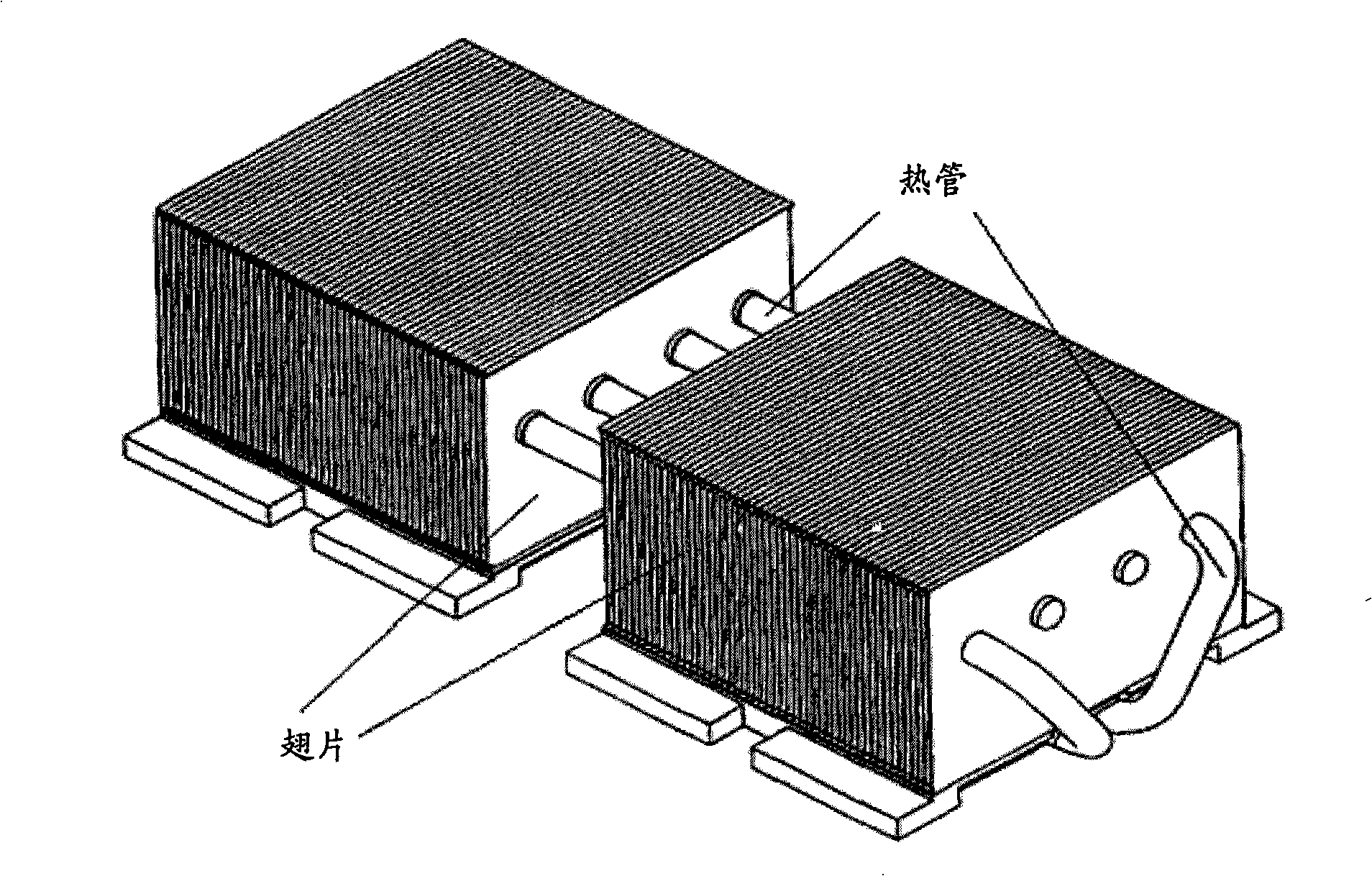

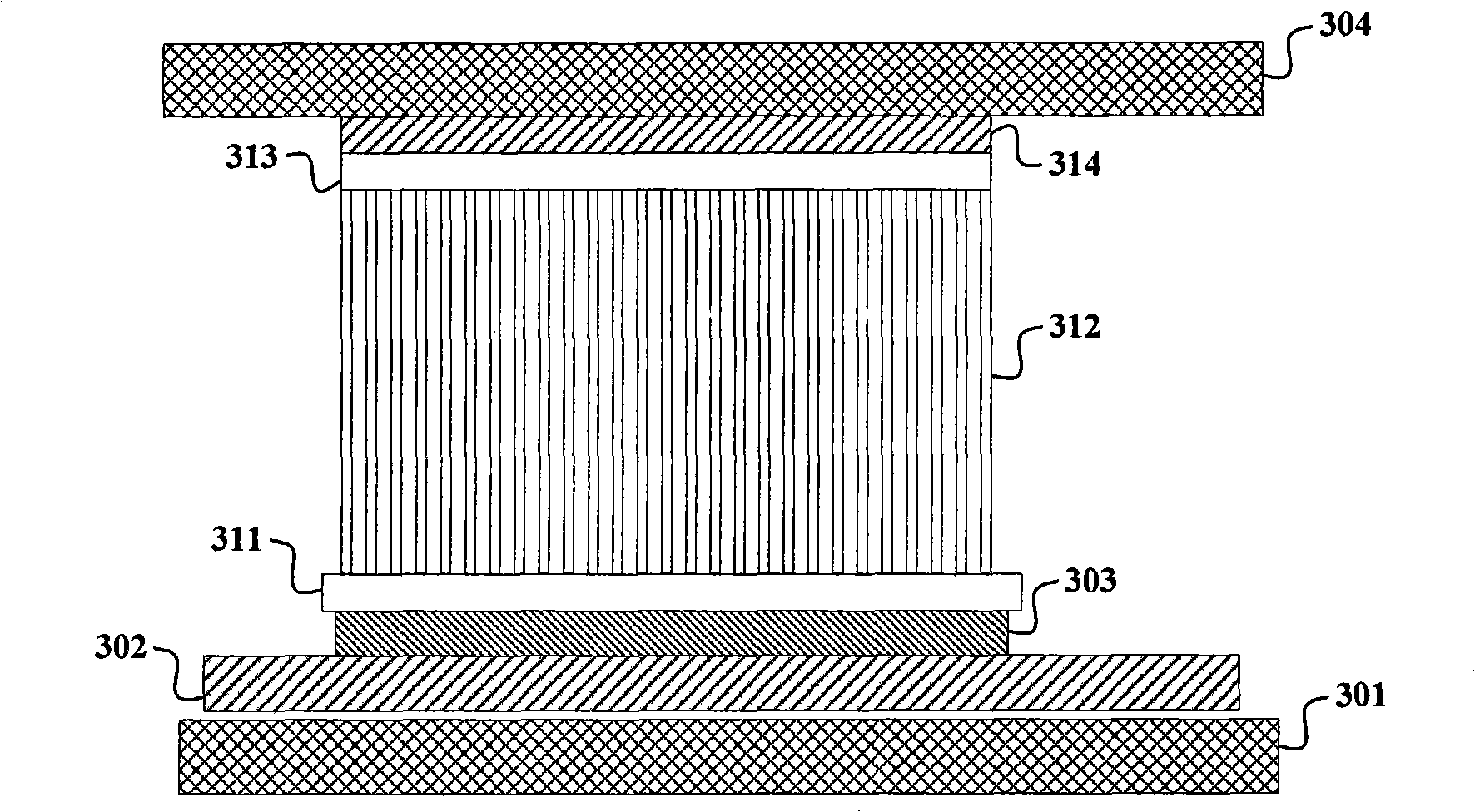

[0028] In the embodiment of the present invention, for the heat sink installed on the chip, the height of the fins of the heat sink is increased to make it close to the case shell; metal sheets and heat-conducting silica gel are placed between the fins and the case shell, and the heat-conducting silica gel is in contact with the case shell , so that the heat of the chip can not only be dissipated through the fins, but also can be conducted to the chassis shell, and the huge surface area of the chassis shell can be used to dissipate heat outward.

[0029] in such as image 3 In the shown case, a circuit board 302 is provided on the bottom plate 301 of the case, and a chip 303 that needs to be dissipated is placed on the circuit board 302 . A heat dissipation device is installed on the outer surface of the chip 303, and the heat dissipation device is also connected to the shell 304 of the chassis. The chassis shell 304 may generally be a removable cover of the chassis.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com