Metallic cord, rubber/cord composite object, and pneumatic tire obtained using the same

A technology of metal cords and composites, which is applied in the field of pneumatic tires, to achieve the effect of improving the wet and heat adhesion characteristics, achieving the effect of increasing the strength and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0073] (1) A brass plating layer is formed on the surface of a steel wire having a diameter of 1.7 mm. Then the electroplating wire was subjected to wire drawing treatment, and the obtained drawn electroplating wire had a diameter of 0.27 mm.

[0074] Brass electroplating is performed by any of the methods described below.

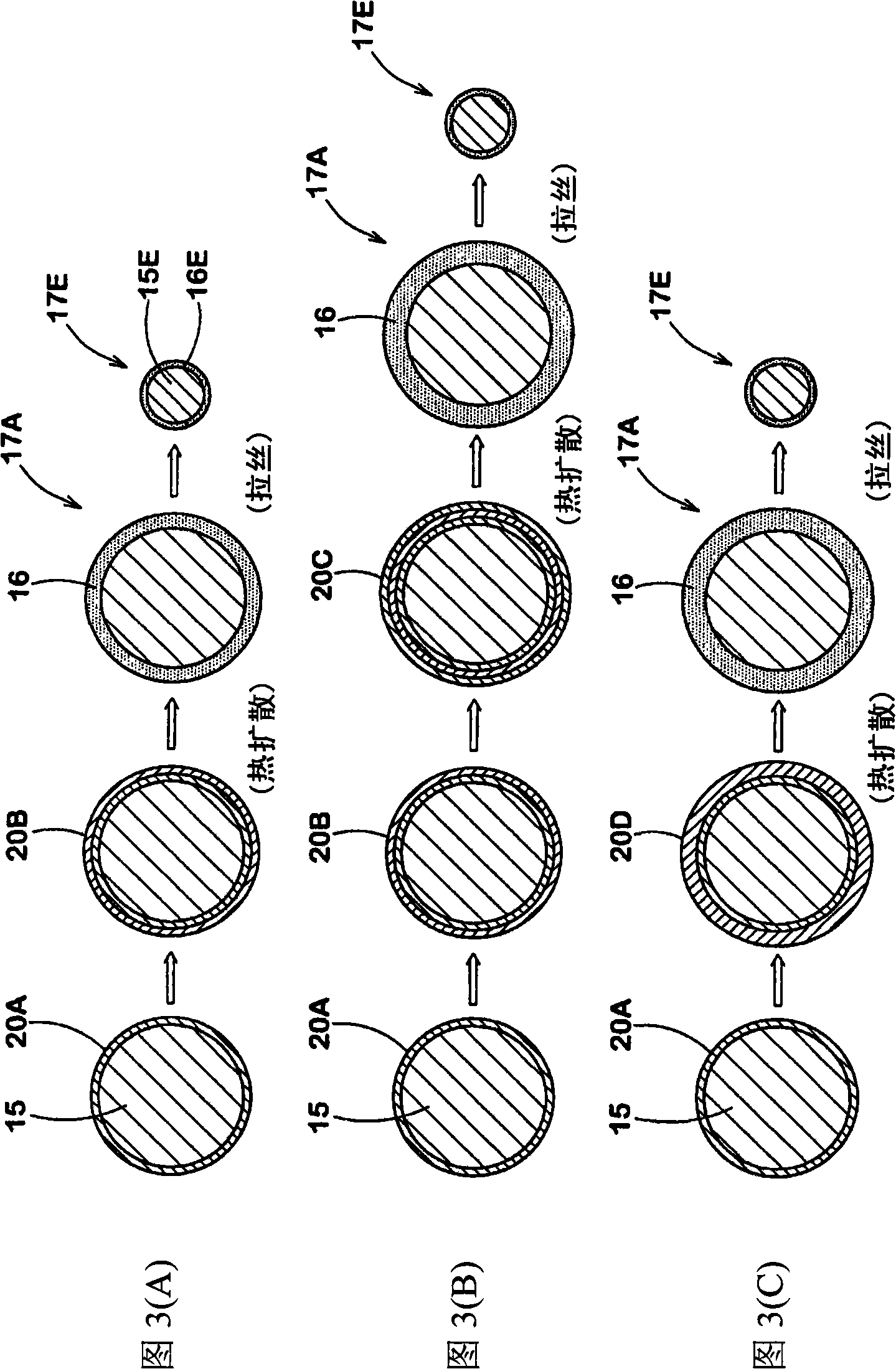

[0075] (A) A copper plating layer and a zinc plating layer are sequentially formed, and then subjected to thermal diffusion treatment to form a binary alloy brass plating layer. This method is referred to as method A.

[0076] (B) sequentially forming a brass coating, a zinc coating, and a third metal coating, and then performing thermal diffusion treatment on them to form a ternary alloy coating. This method is referred to as method B.

[0077] (C) sequentially forming a brass coating and a zinc alloy (zinc / nickel alloy, or zinc / cobalt alloy) coating, and then performing thermal diffusion treatment to form a ternary alloy coating. This method is refer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com