Apparatus and method for evaporating and concentrating liquid

A technology of membrane evaporation and evaporator, which is applied in the field of liquid evaporation and concentration equipment, can solve the problems of uneven temperature of hot side fluid, influence of liquid evaporation efficiency, easy blockage of hollow fiber membrane flow channel, etc., and achieve the effect of reducing sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

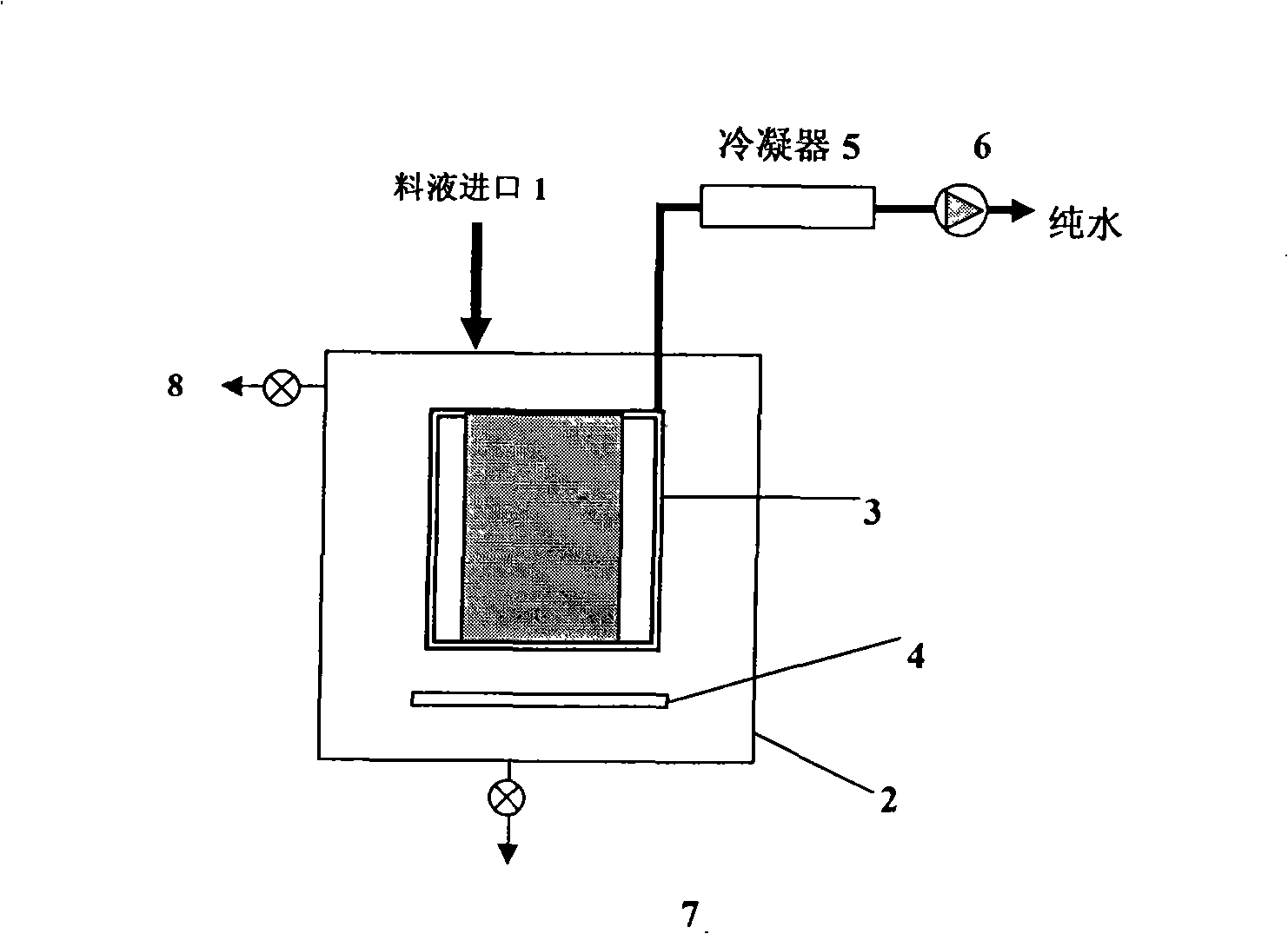

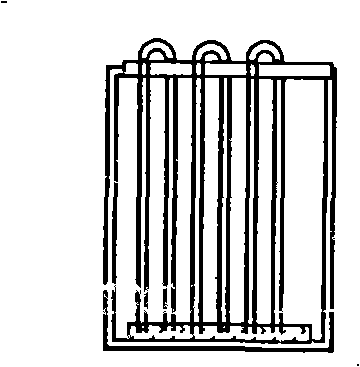

[0017] like figure 1 As shown, the membrane evaporation part of the present invention includes: a hot pool 2; a feed liquid inlet 1 arranged on the hot pool 2; a submerged hydrophobic hollow fiber membrane evaporator 3 arranged in the hot pool 2; a perforated exposure to control membrane fouling Trachea 4 is arranged on the bottom of evaporator 3; hollow fiber condenser 5 arranged on the outside of heat pool 2; negative pressure pump 6 is arranged behind the pure water outlet of condenser 5, adopts negative pressure suction, and water vapor Introduce in condenser 5 to carry out condensation collection.

[0018] Solids such as concentrated crystalline salt are discharged from the evaporator from the low discharge outlet 7 arranged at the bottom of the hot pool 2 .

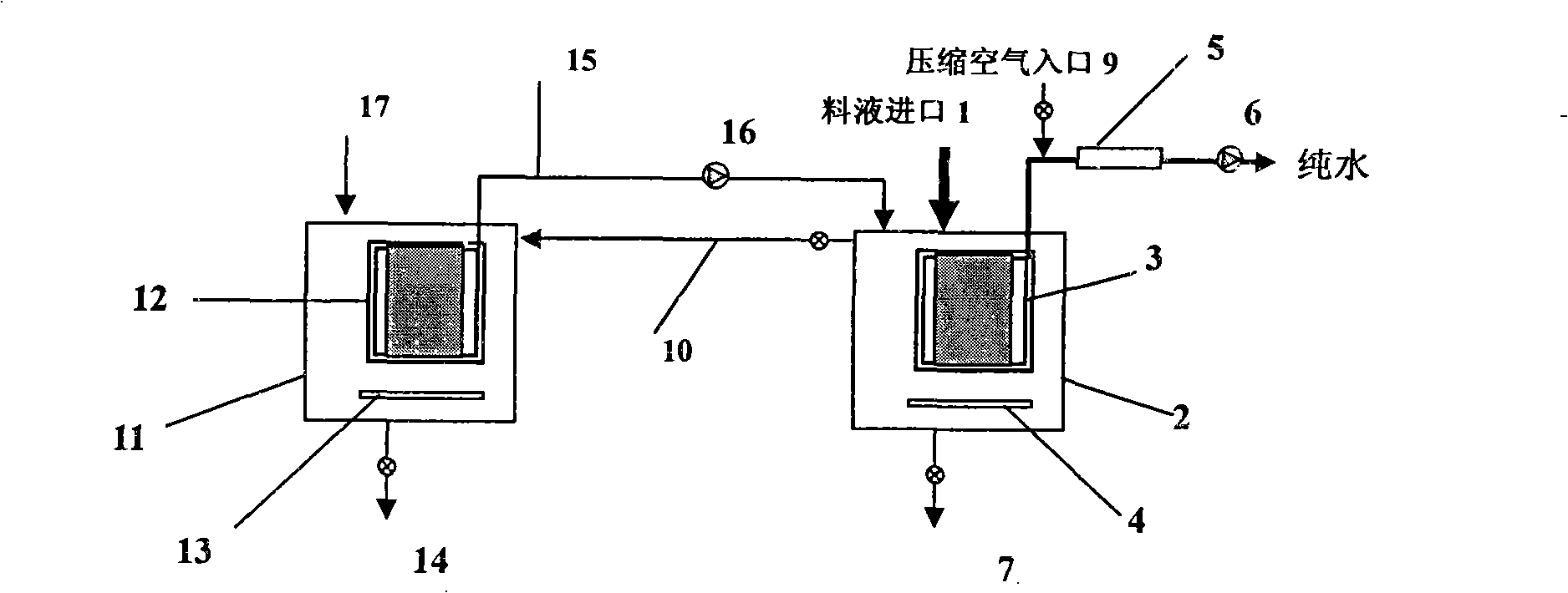

[0019] like figure 2 It is a schematic diagram of the main process of the MEC system. like figure 2 As shown, the hot pool 2 and the reaction filter pool 11 are connected through the floating pollutant overflo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com