Treating process of dilute emulsified oily watewater

A treatment process and oxidation treatment technology, applied in the field of water treatment, can solve problems such as large fluctuations in effluent indicators, air pollution, and impact on clean natural water sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

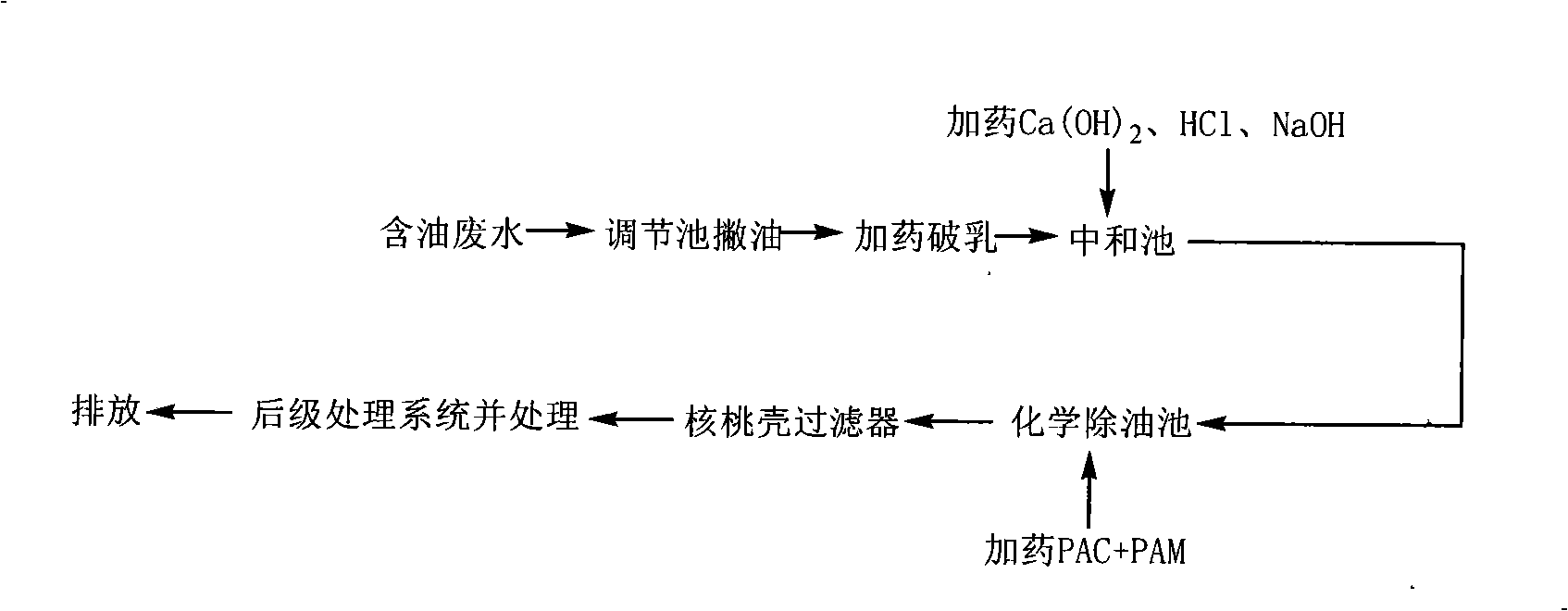

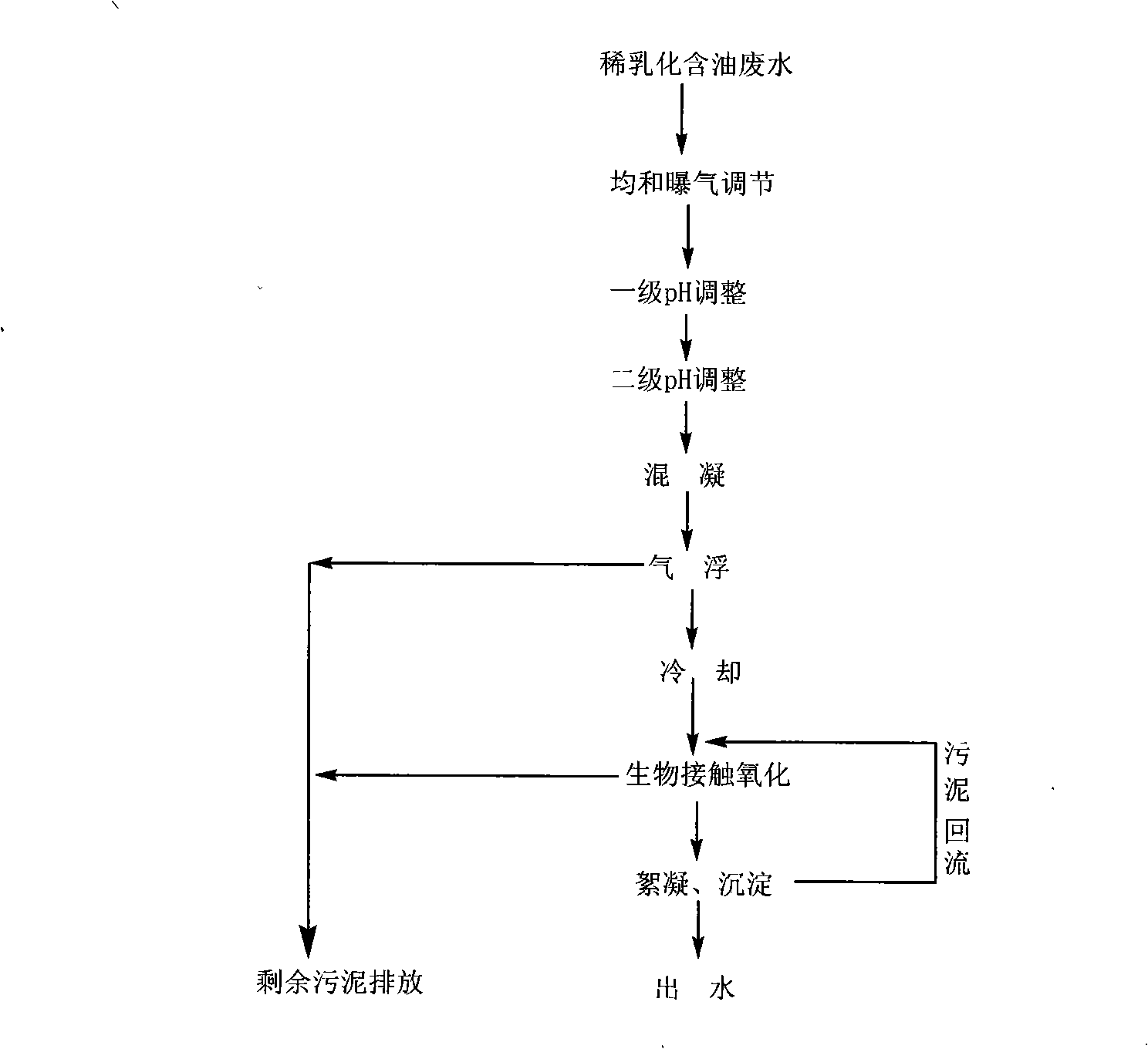

[0047] The process of the present invention has been applied to Baosteel No. 5 cold-rolled steel strip project, and the treatment process of cold-rolled dilute emulsified oily wastewater is as follows:

[0048] (1) Uniform aeration adjustment, air is passed through the adjustment tank, and the air-water ratio is 5:1 to make the water quality and water quantity even;

[0049] (2) Primary and secondary pH adjustments, dosing chemicals through pneumatic regulating valves or metering pumps, and the dosage is interlocked with the pH meter for controlling wastewater;

[0050] (3) Coagulation and air flotation, add Jingshuiling with a concentration of 5% as a flocculant, and the dosage is 10mg / L, so that part of the dissolved oil in the wastewater can be separated out, and removed together with the slick oil under the action of air flotation ;

[0051] (4) Cooling, which can be the first-level cooling and cooling, or the second-level and above cooling;

[0052] (5) Biological contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com