High on-stage voltage right-handed LED integrated chip and manufacturing method thereof

A technology of integrated chips and manufacturing methods, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of poor high-voltage resistance performance of LED integrated chips, and achieve a small footprint, small chip integration, and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

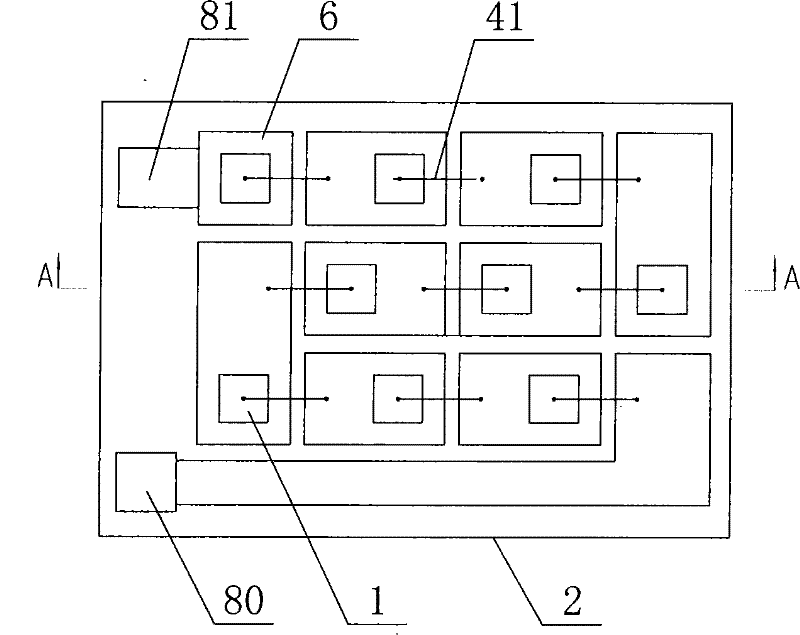

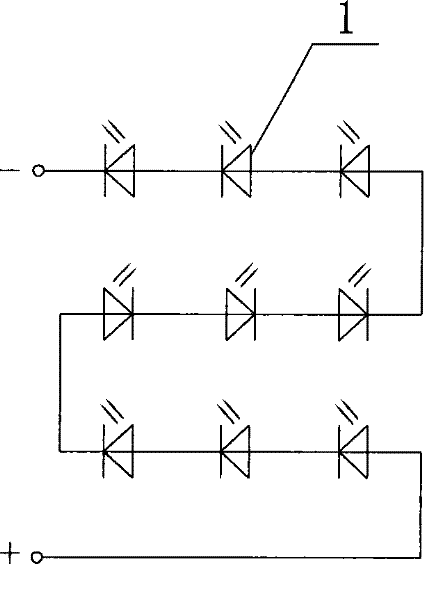

[0045] like figure 1 , image 3 , Figure 4 As shown, the high conduction voltage front-mounted LED integrated chip of this embodiment includes nine LED bare chips 1 and a silicon substrate 2, the LED bare chips 1 are single-electrode chips, and the LED bare chips 1 include gallium arsenide ( GaAs) substrate 10 and N-type epitaxial layer 11, P-type epitaxial layer 12, certainly, described substrate 10 also can be the substrate of other materials such as silicon carbide (SiC), described silicon substrate 2 is P-type silicon substrate, the front side of the silicon substrate 2 is formed with a thermally conductive insulating layer, and the thermally conductive insulating layer is solely composed of a second thermally conductive insulating layer 5 formed by deposition, and the second thermally conductive insulating layer 5 is composed of a silicon nitride layer, The thermal conductivity of silicon nitride is very high, and its thermal conductivity is more than 100 times higher ...

Embodiment 2

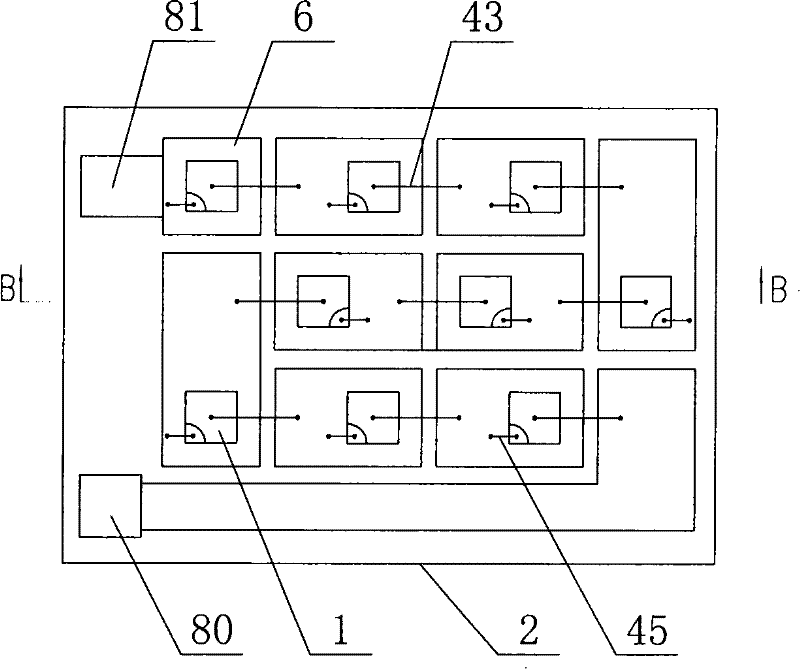

[0054] like figure 2 , image 3 , Figure 5 to Figure 9 As shown, the difference between this embodiment and Embodiment 1 is that: the LED bare chip 1 is a double-electrode chip, and the substrate 10 is aluminum oxide (sapphire, Al 2 O 3 ) substrate, the P-type epitaxial layer 12 and the N-type epitaxial layer 11 are soldered to two adjacent metal layers 6 through metal wires 43 and 45 respectively.

[0055] The remaining features of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0057] like figure 1 , image 3 , Figure 10 As shown, the difference between the high turn-on voltage front-mounted LED integrated chip of this embodiment and the first embodiment is that a layer of N+ diffusion layer 3 is diffused inwardly from the front side of the silicon substrate 2 described in this embodiment, and the N+ A first thermally conductive insulating layer 4 is grown on the diffusion layer 3, a second thermally conductive insulating layer 5 is deposited on the first thermally conductive insulating layer 4, and a metal layer 6 is deposited on the second thermally conductive insulating layer 5, that is, the The thermally conductive insulating layer is composed of the first thermally conductive insulating layer 4 formed by growth and the second thermally conductive insulating layer 5 formed by deposition, the first thermally conductive insulating layer 4 is made of silicon dioxide, and the second thermally conductive insulating layer 5 is composed of silicon ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com