Numerical controlled plate thermal stress surface shaping machine

A curved surface forming and thermal stress technology, which is applied in the mechanical structure of curved surface forming machines and in the field of steel plate curved surface forming processing, can solve the problems of CNC automatic processing and measurement errors, poor controllability and reproducibility, and large pollution of the working environment to achieve improvement The degree of automation, the controllable energy input, and the effect of easy automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with specific embodiment and accompanying drawing, the present invention is described in detail as follows:

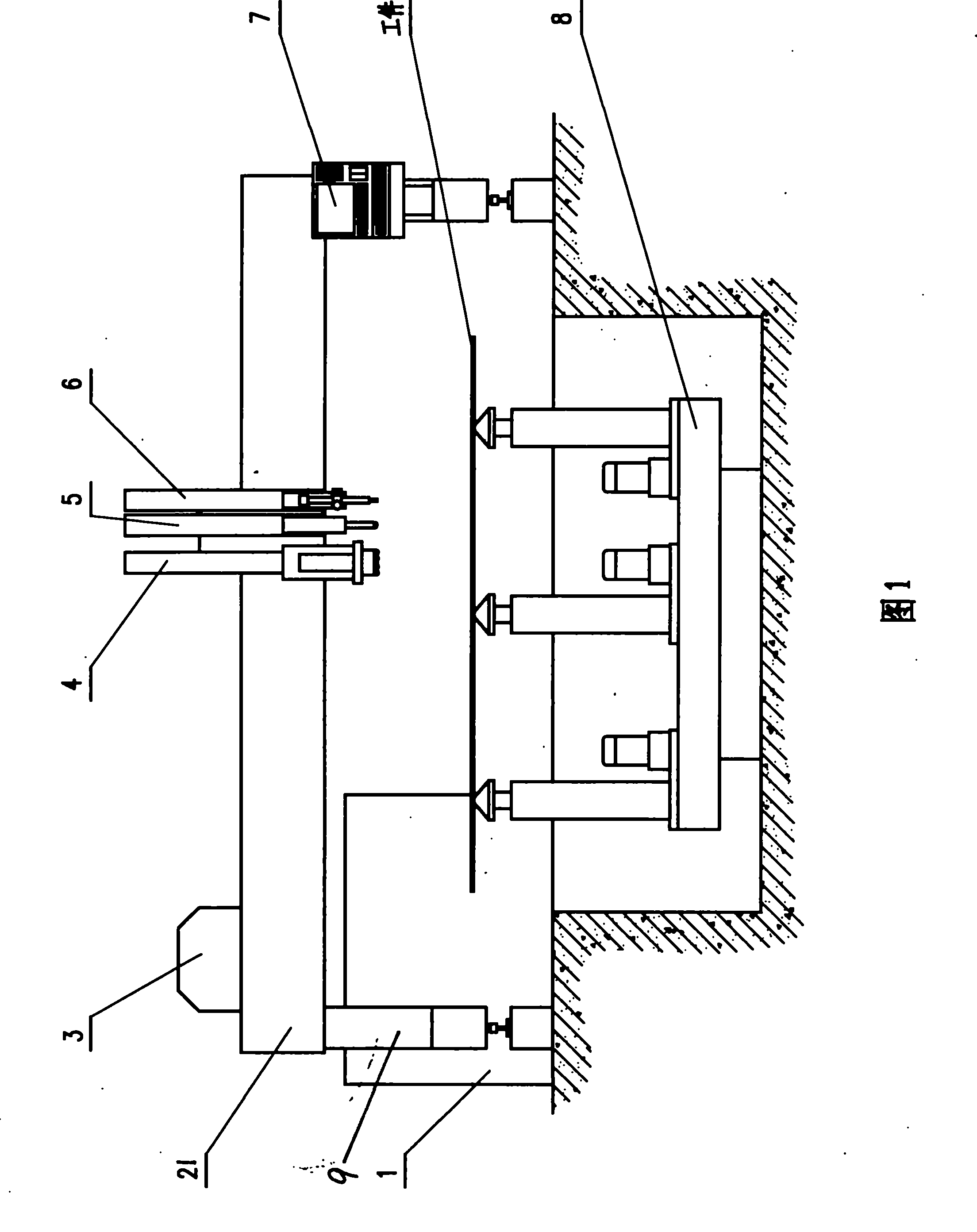

[0042] The present invention is a numerically controlled plate heat stress curved surface forming machine, mainly composed of X, Y traveling mechanism 2, heating device 4, detection device 5, marking device 6, support mechanism 8, cooling device 1 and control system 7.

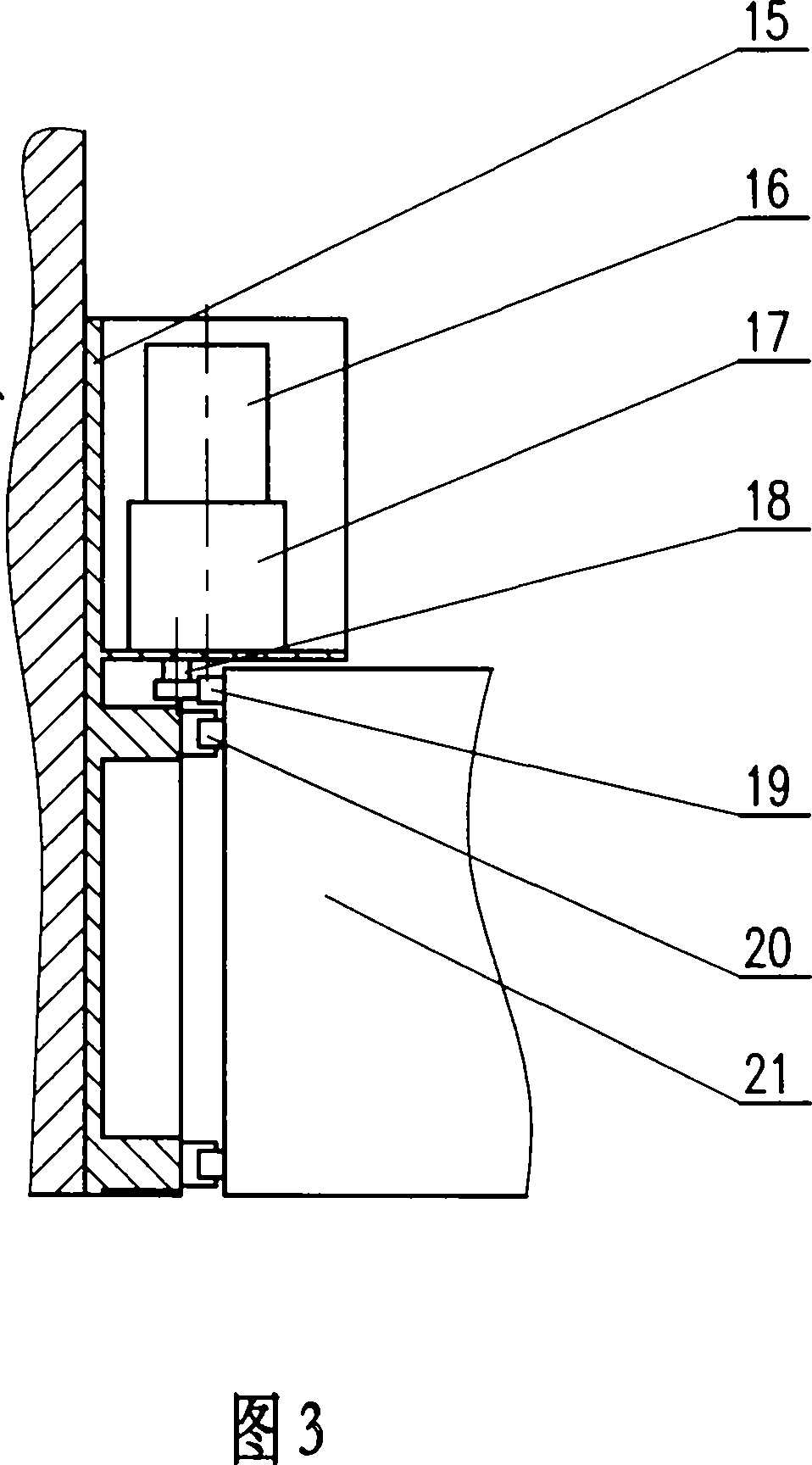

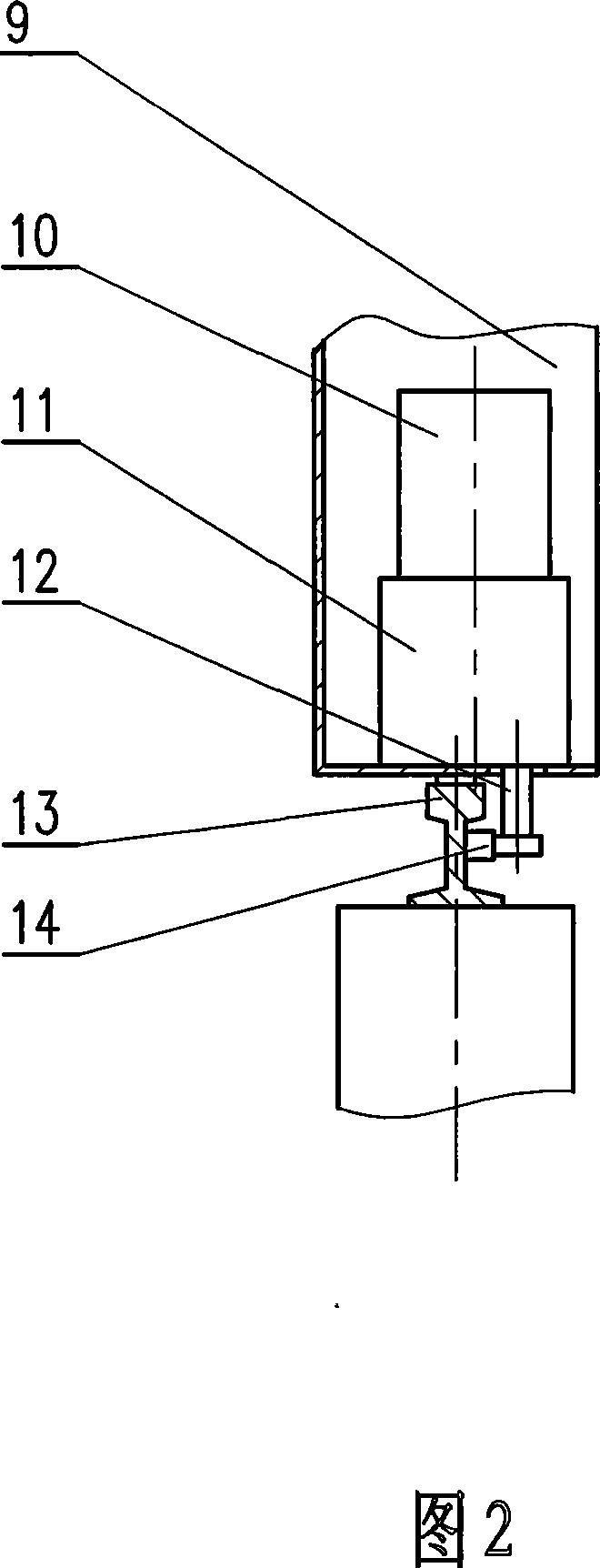

[0043] Specifically, a numerically controlled sheet material thermal stress curved surface forming machine, which mainly consists of beam 21, end frame 9, trolley 15, and guide rail 13 components to form X, Y traveling mechanism 2, and the power supply 3 of high-frequency induction heater is installed on the beam. The guide rail 20 and the trolley 15 are equipped with a heating device 4, a detection device 5, a marking device 6, and a control system 7, and a support mechanism 8 for placing heated steel plates is provided under the beam 21, which is different from the prior ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com