A fixing unit for sealant uv cure machine

A technology of fixed unit and ultraviolet light, applied in optics, electrical components, nonlinear optics, etc., can solve the problems of large size of photomask supporting glass, lower work efficiency, and increased manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Several exemplary embodiments of the present invention will now be described in detail with reference to the accompanying drawings. In the following description, for the sake of brevity, detailed descriptions of conventional functions and structures have been omitted.

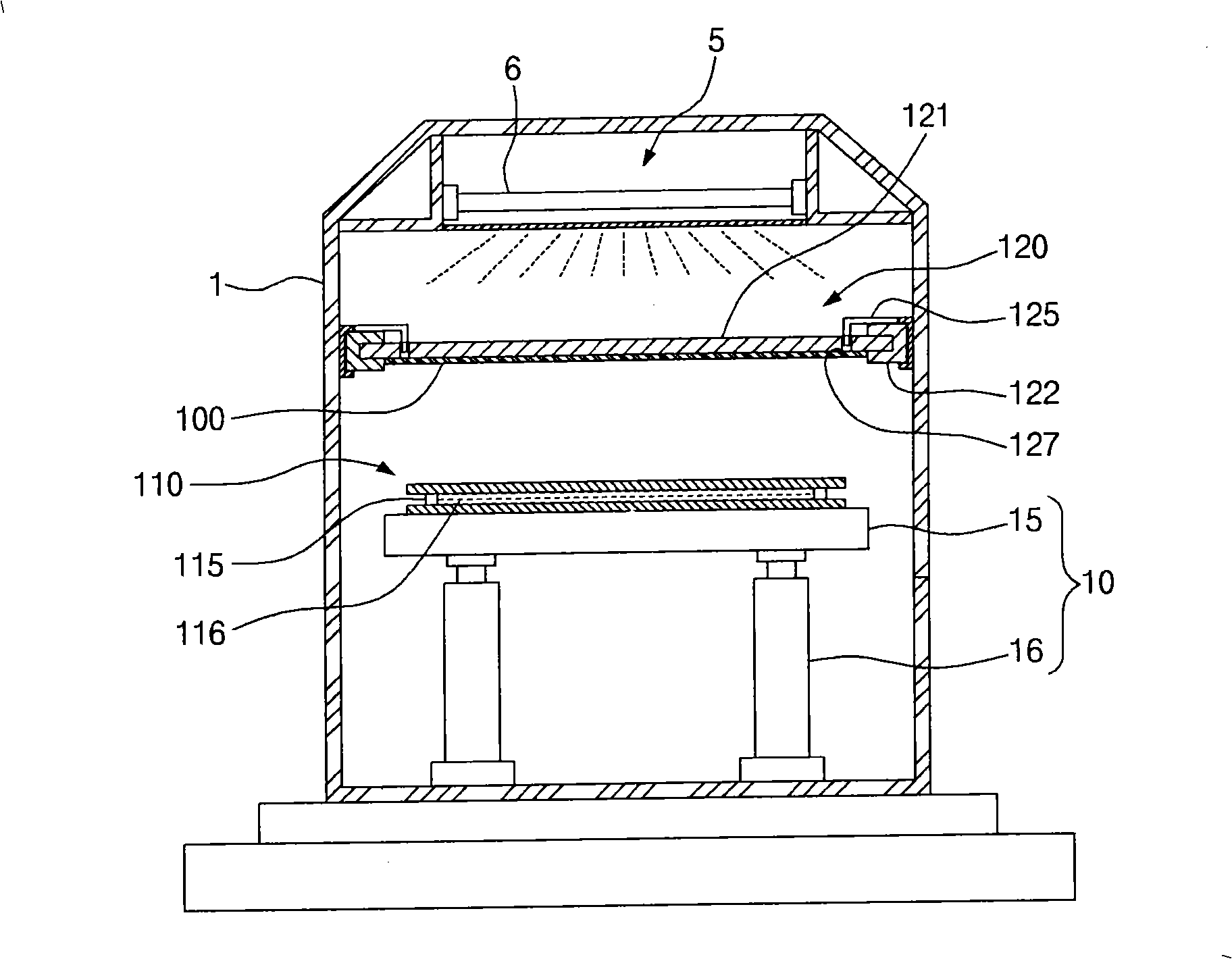

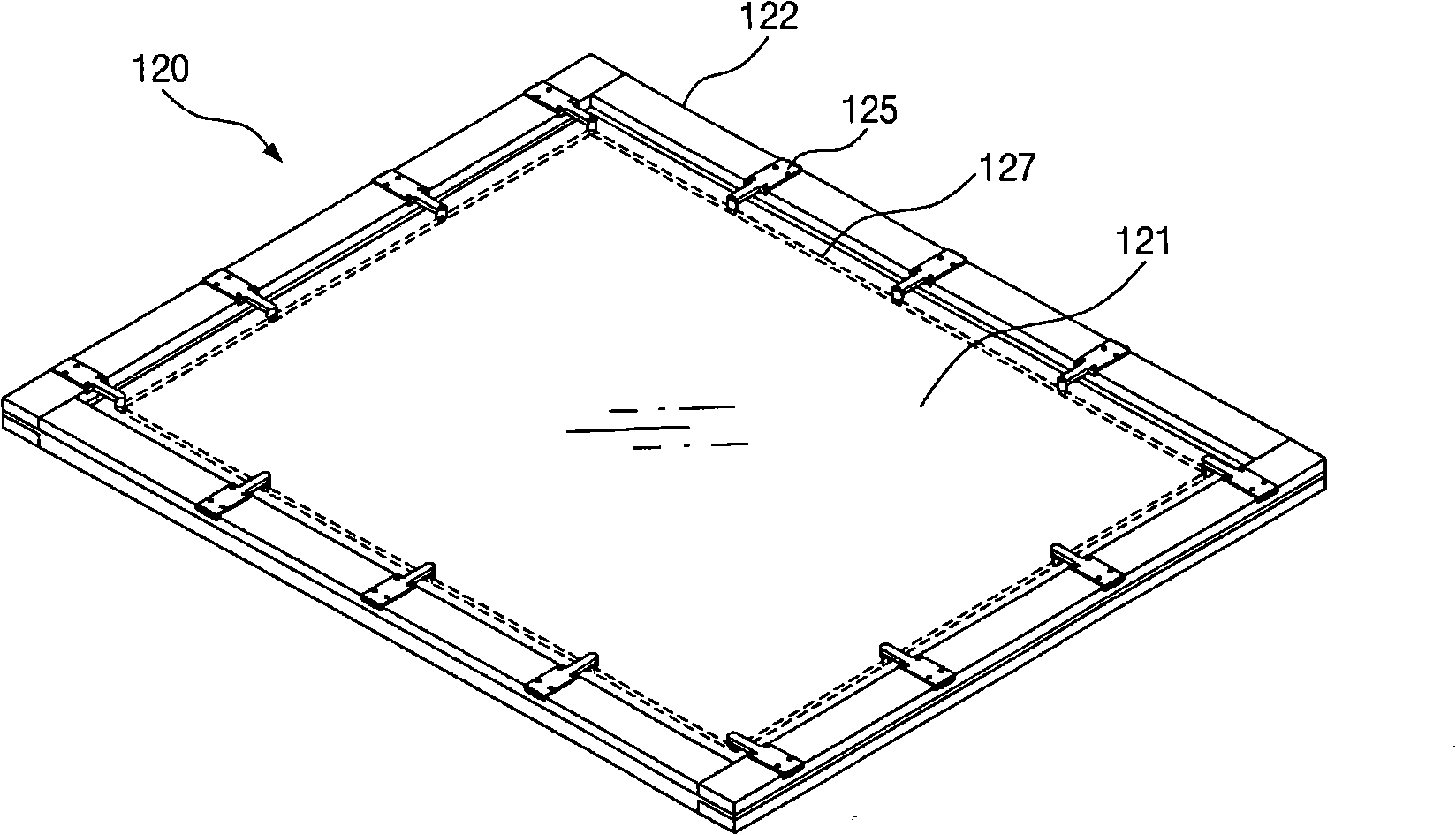

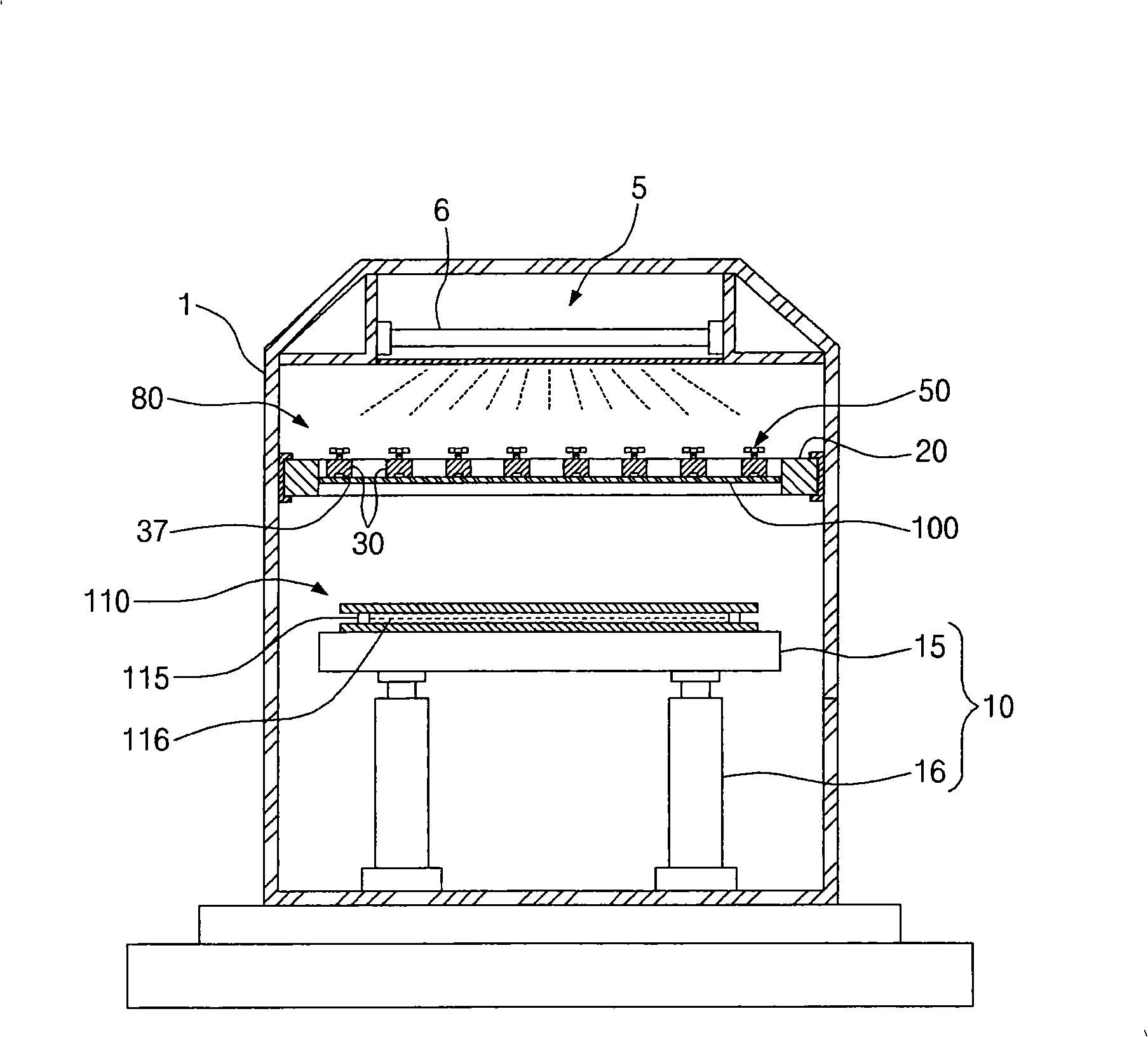

[0043] image 3is a schematic cross-sectional view of a sealant UV curing machine, in which a fixing unit according to an exemplary embodiment of the present invention is used. Figure 4 It is a partially exploded perspective view showing a fixing unit 80 for a sealant UV curing machine according to an exemplary embodiment of the present invention. Figure 5 is an exploded view showing Figure 4 Part "A" in .

[0044] Such as image 3 As shown, the sealant UV curing machine includes a container chamber 1 , a light emitting unit 5 , a photo cover glass fixing unit 80 , and a substrate supporting unit 10 .

[0045] The chamber 1 has a predetermined size and provides a space for performing sealant curi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com