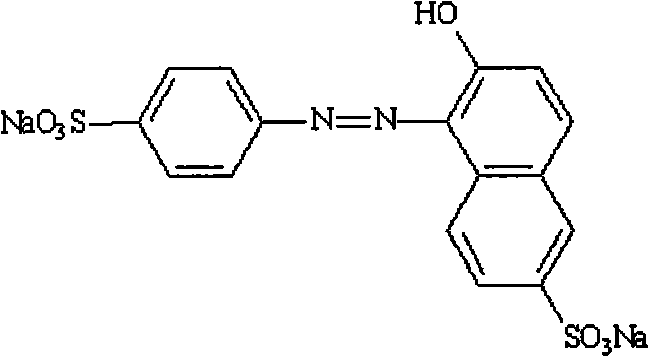

Preparation method for enhancing yield of edible sunset yellow

A technology of yellow yield and p-aminobenzenesulfonic acid, which is applied in the field of preparation of food coloring, can solve the problems of low conversion rate, affecting the purity and quality of final products, etc., and achieve the effect of improving reaction effect and good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

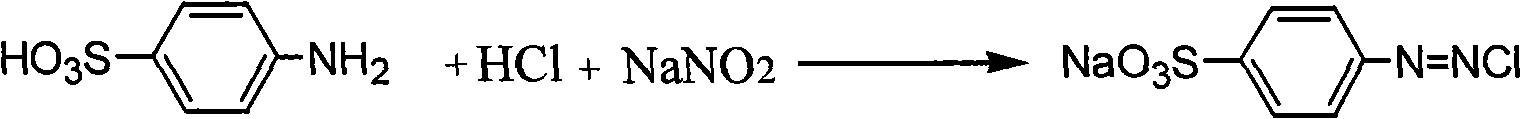

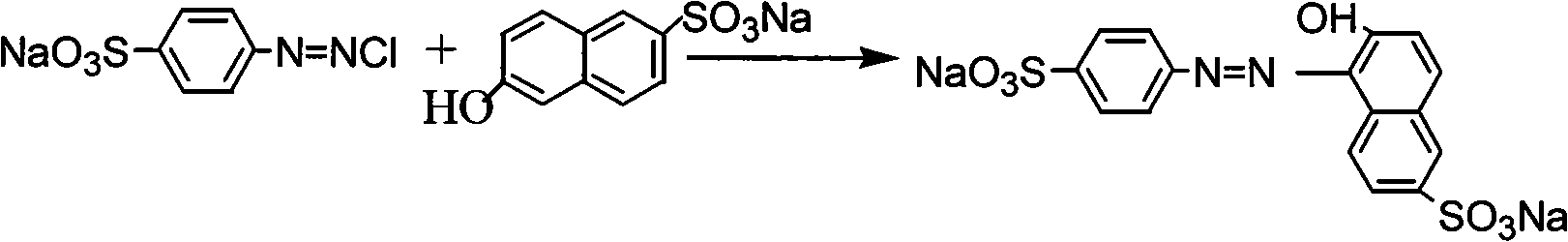

Method used

Image

Examples

Embodiment 1

[0025] In a 500mL four-necked flask, add 180mL of hot water (60°C), then add 2g of polyethylene glycol 1000 (PEG-1000), add 35g of 99.0% p-aminobenzenesulfonic acid (0.2mol) under rapid stirring, and stir for ten minutes, cooled to room temperature, and added industrial hydrochloric acid. Continue to cool to 0-5°C, add 47.3g 30% sodium nitrite solution (0.202mol) dropwise under the liquid, and maintain the temperature at 5-12°C (keep the blue color of the Congo red test paper and the light blue color of the potassium iodide starch test paper. Continue to Stir for 20 minutes, add a small amount of sulfamic acid to eliminate excess nitrous acid.

[0026] Add 500ml of water and 2.5g of polyethylene glycol 1000 (PEG-1000) into a 1000ml beaker, and add 57.6g of 87.1% sodium scheffrate (0.204mol) under stirring. Sprinkle sodium carbonate slowly and stir for 15 minutes. After cooling to 12-15°C, it becomes milky white thick paste, pH 10-11. Slowly add the diazonium salt under stir...

Embodiment 2

[0028] Replace 2 g of polyethylene glycol 1000 (PEG-1000) with 0.5 g of polyethylene glycol 1000, and the rest are the same as in Example 1. The total reaction conversion rate was measured to be 98.7% (calculated as p-acid), and the HPLC purity of sunset yellow in the coupling solution was 92.6% (239nm).

Embodiment 3

[0030] Replace 2.5 g of polyethylene glycol 1000 (PEG-1000) with 0.8 g of polyethylene glycol 1000, and the rest are the same as in Example 1. The total reaction conversion rate was measured to be 97.8% (calculated as p-acid), and the HPLC purity of sunset yellow in the coupling liquid was 91.2% (239nm).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com