Chemically-reactive dyes with sulfanyl and beta-sulfate ethylsulfonyl

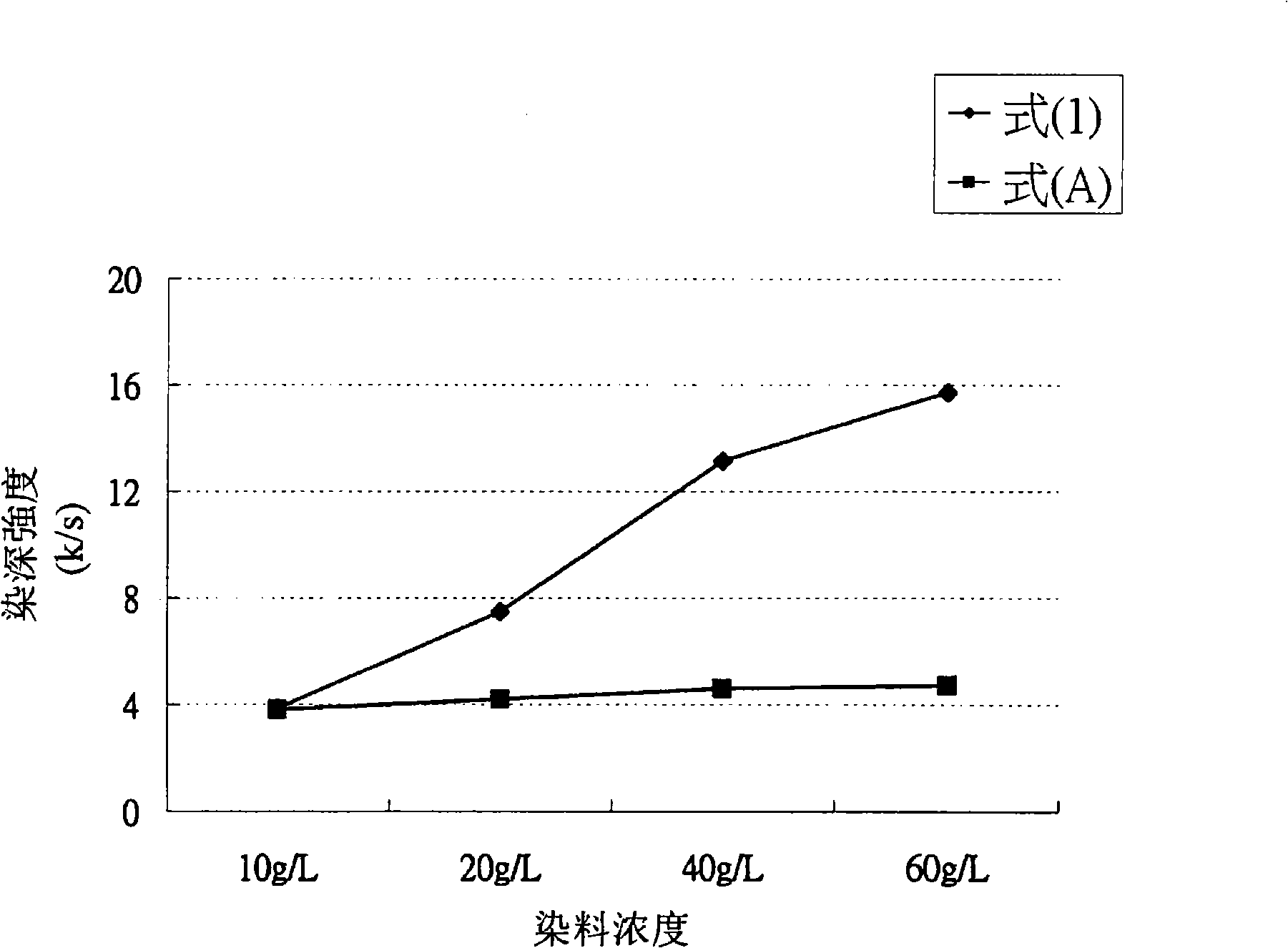

A reactive dye, ethylsulfonyl technology, applied in the direction of reactive dyes, organic dyes, azo dyes, etc., can solve the problems of poor solubility in alkali resistance, inability to apply cold press dyeing or continuous dyeing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

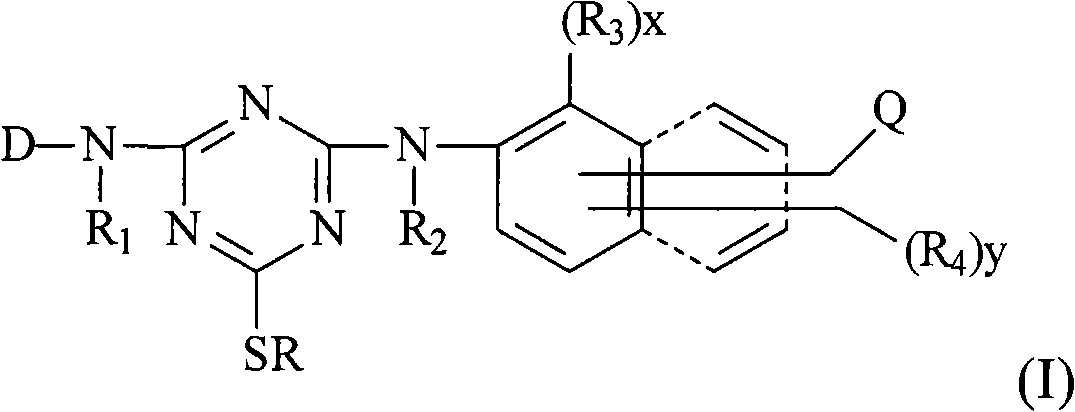

Method used

Image

Examples

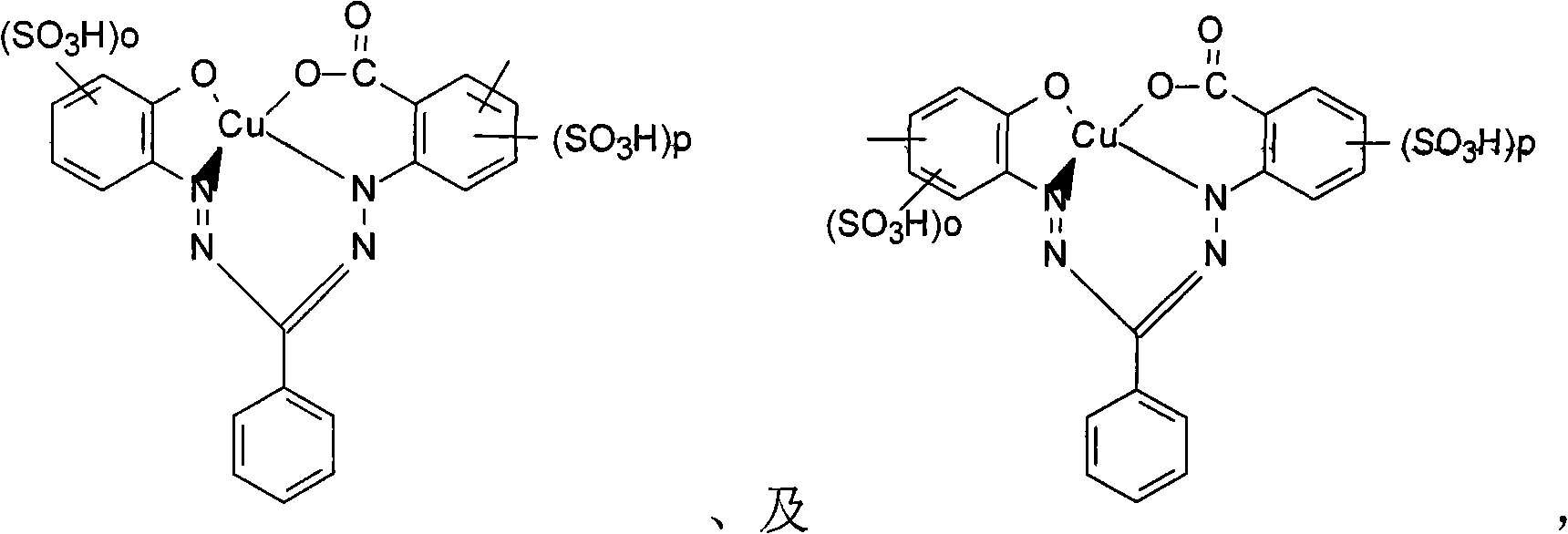

Embodiment 1

[0140] a) Disperse 28 parts of cyanuric chloride in 150 parts of water at 0°C, and then add 90 parts of formazan Chromophores (Cuprate(3-), [2-[[[[3-amino-2-(hydroxy-O)-5-sulfophenyl]azo-N2]phenylmethyl]azo-N1]-4-sulfobenzoato(5- )-O]-(Formazan base)), with sodium carbonate (Na 2 CO 3 ) adjusting the pH value to 5-5.5, controlling the temperature below 10-15°C, and reacting at the temperature for 2 hours to obtain a blue product for later use.

[0141] b) Add 21 parts of thioglycolic acid to the aqueous solution obtained in the above step (a), adjust the pH value of the reaction solution to between 7 and 8 with sodium carbonate powder at 20 to 25 ° C, and react for 2 hours with Generally, the filter cake is taken out by acid precipitation and salt precipitation, and the blue product is obtained for later use.

[0142]

[0143] c) After redissolving the filter cake in step (b) with 100 parts of water, add 5 parts of N-ethylaminophenyl-3-(beta-sulfato-ethylsulfone) and ad...

Embodiment 2

[0146] a) Disperse 10 parts of cyanuric chloride in 70 parts of water at 0°C, and then dropwise add 12 parts of 2-amino-5-naphthalene-7-sulfonic acid (2-Amino-5-hydroxynaphthalene-7- sulfonic acid), adjust the pH value of the reaction solution to 1-3 with 15% sodium carbonate aqueous solution, control the temperature below 5°C, keep the temperature and react for 2 hours, filter and take the filtrate for later use.

[0147] b) Take 80 parts of water at 0°C, add 15 parts of 2-aminonaphthalene-1,5-disulphonic acid (2-aminonaphthalene-1,5-disulphonic acid) and 14 parts of 32% hydrochloric acid aqueous solution to fully stir and disperse, then add 4 parts of sodium nitrite aqueous solution, control the diazotization reaction at 0-5 ° C for about 0.5 hours to complete, add the filtrate obtained in the above step (a), slowly adjust the reaction pH value to 6-8 with sodium carbonate, and react 3 An orange product was obtained after 1 hour for further use.

[0148] c) Add 5 parts of T...

Embodiment 3

[0152] a) Take 50 parts of water and add 8 parts of m-Aminophenyl Urea (m-Aminophenyl Urea), adjust the solution with sodium carbonate and set aside.

[0153] b) Take 70 parts of water at 0°C and add 19 parts of 7-aminonaphthalene-1,3,6-trisulphonic acid (7-aminonaphthalene-1,3,6-trisulphonic acid), dissolve with sodium carbonate and then add After 4 parts of sodium nitrite, 13 parts of 32% hydrochloric acid aqueous solution was added dropwise and stirred thoroughly, and the diazotization reaction was carried out at a temperature of 5-10°C for about 0.5 hours. The aqueous sodium carbonate solution slowly adjusted the reaction pH value to 5-6, and after 0.5 hours of reaction, a yellow product was obtained for future use.

[0154] c) Disperse 10 parts of cyanuric chloride in 150 parts of water at 0°C, then pour it into the solution of step (b), slowly adjust the reaction pH value to 5-6 with 15% aqueous sodium carbonate solution, and filter to obtain a yellow color after the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com