Tobacco on-line laser boring mechanical installation

A technology of laser drilling and mechanical devices, applied in laser welding equipment, tobacco, cigarette manufacturing, etc., can solve the problems of complex structure, increase of clamping manipulators, increase of cost, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

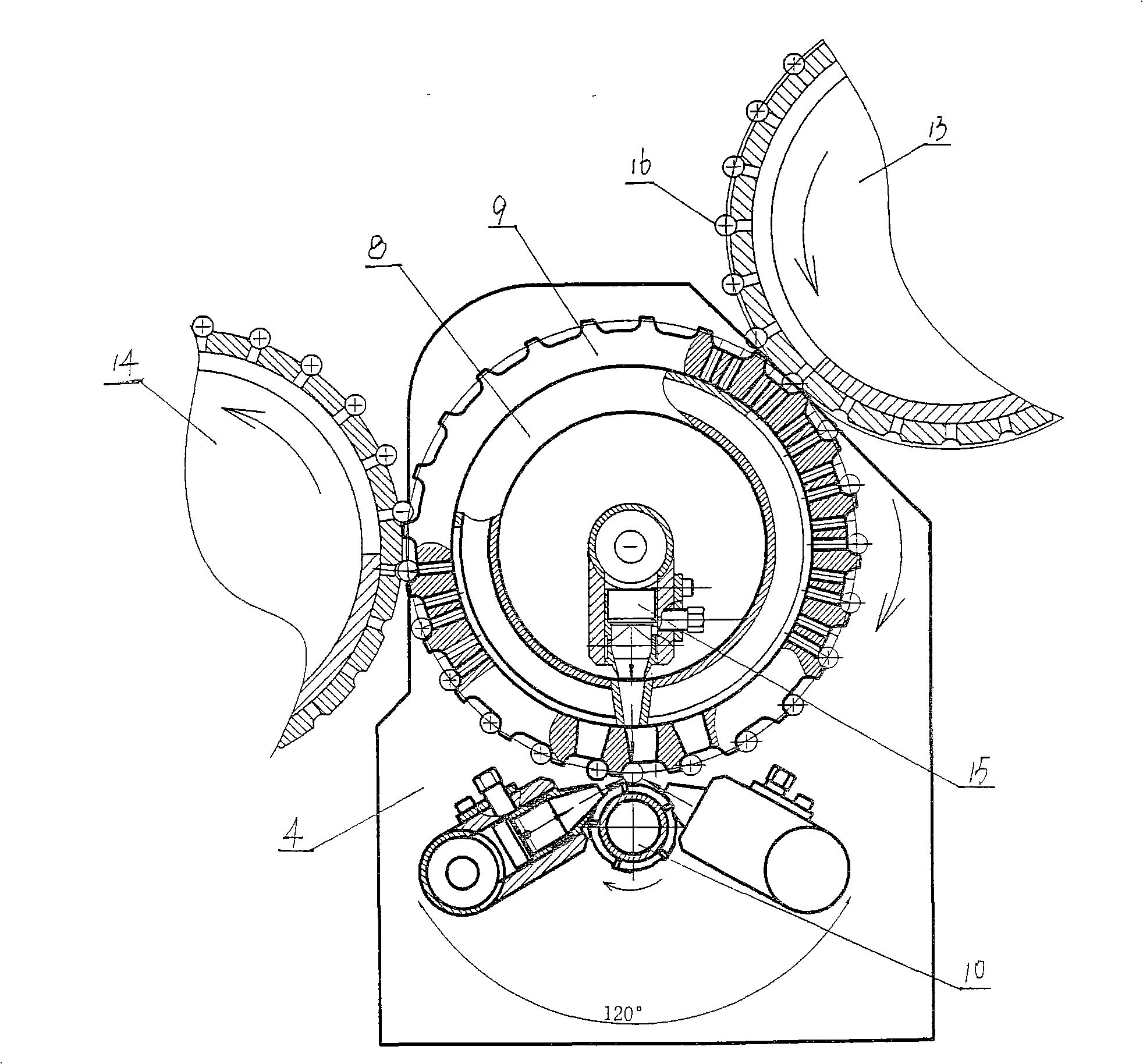

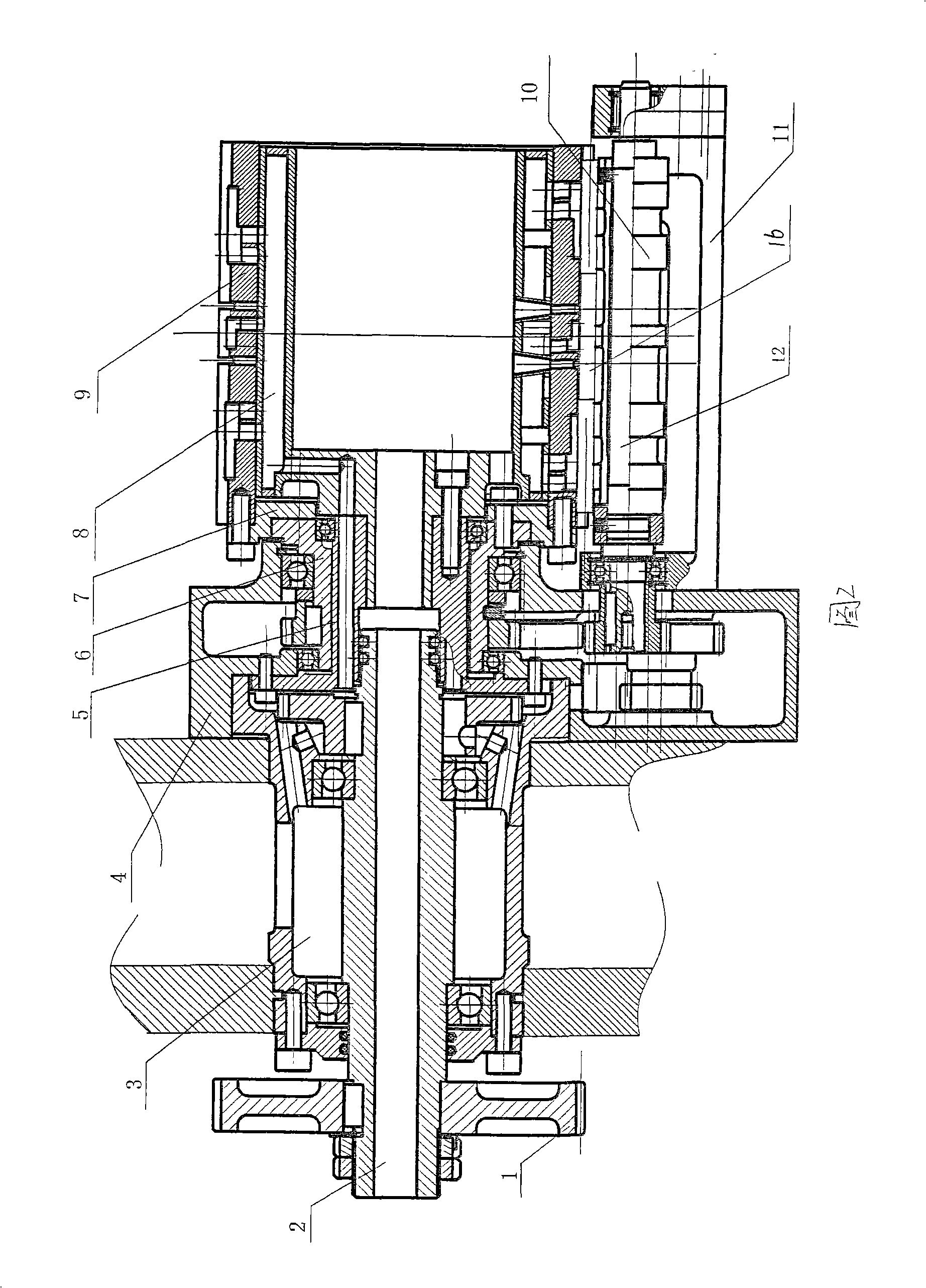

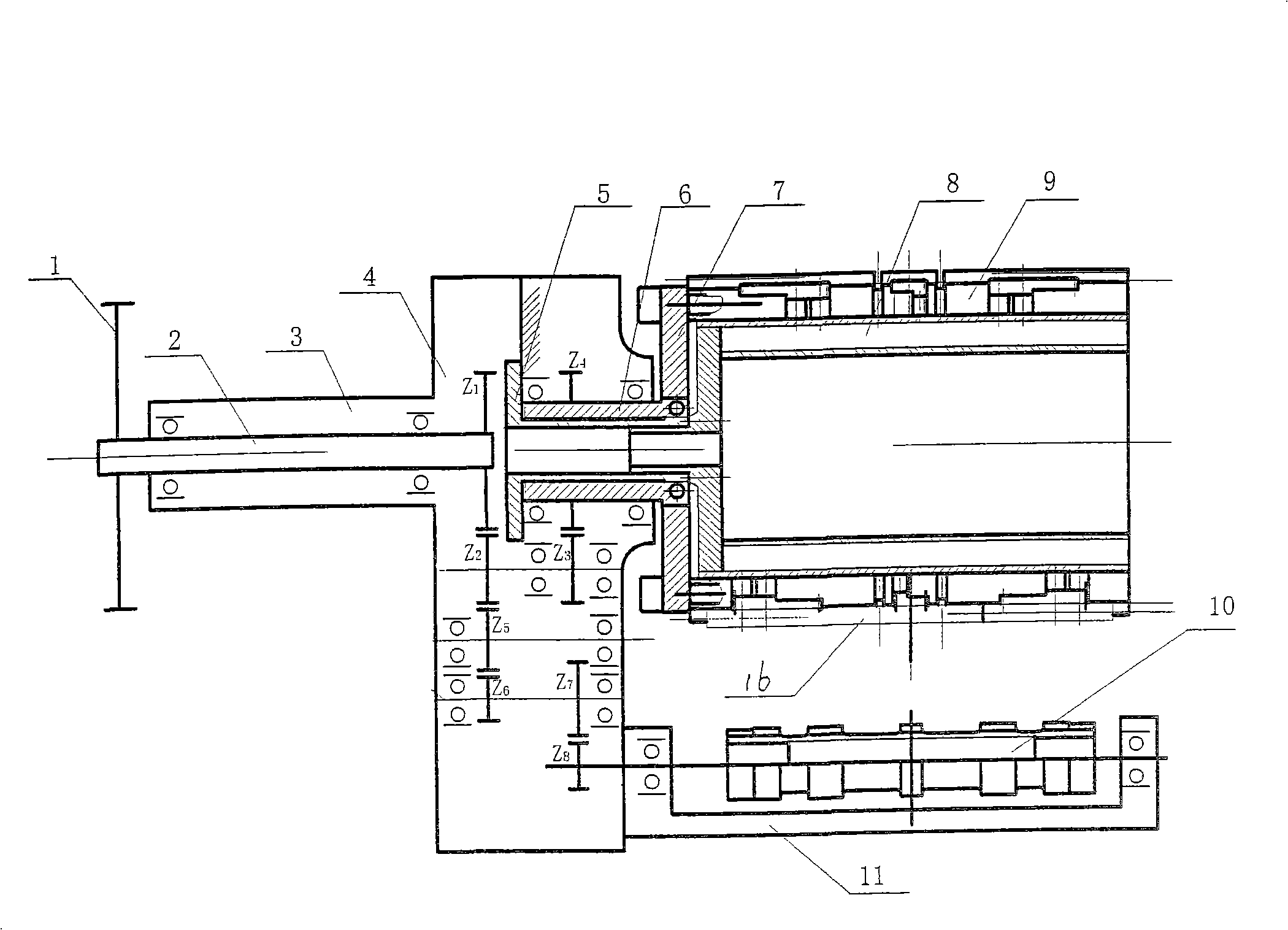

[0024] like figure 1 As shown in -8, a cigarette online laser drilling mechanical device is installed between the drying wheel 13 and the cutting wheel 14 of the PASSIM cigarette rolling machine. The punching mechanism and the gear transmission mechanism are composed of input gear 1, input shaft 2, bearing housing 3, and gear transfer case 4. The input gear 1, input shaft 2, bearing housing 3, and gear transfer case 4 are on the same axis in turn. Installation, the bearing housing 3 and the gear transfer case 4 are combined, and the gear transmission of the gear transfer case 4 is driven by two parallel output shafts, one of which is the output shaft 6 of the perforated drum wheel, and the other is the output shaft 12 of the smoke rubbing wheel; The above-described adsorption transmission mechanism is composed of a support seat 5, a connecting flange 7, a negative pressure suction valve 8, and a perforating drum 9. The output shaft 6 of the perforating drum is a hollow shaft w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com